Metaval is an Australian engineering firm that has been leading the pipeline industry for over 50 years since its establishment in 1967. Our state-of-the-art manufacturing facilities, located in Australia, India, and the UAE, make us a perfect one-stop shop for all pipeline needs. We are proud pioneers in the manufacturing of valves, flow measurement, instrumentation, and forging products. Our products are highly customisable to meet your specific requirements. With over 55+ years of experience, our team of highly specialised industry veterans ensures that only the best products pass our stringent quality checks.

Our comprehensive range of services includes design, forging, casting, flow calibration, and lab testing.

Our company comprises four divisions: Metavalve, Metaflow, Metalok, and Metaforge, each offering a diverse range of products across different industries and sectors, including oil and gas, energy and power, pulp and paper, chemical, petrochemical, sugar, fertiliser, dairy, food processing, mining and minerals, water, and wastewater, and many more.

Premium quality valves: customisable, reliable, and globally trusted

Our comprehensive valve portfolio comprises a wide range of options, including Gate Valves, Globe Valves, Ball Valves, Butterfly Valves, Check Valves, and Strainers, among others. Each valve is meticulously manufactured using cutting-edge technology and high-quality materials to guarantee exceptional reliability, durability, and efficiency. We understand that different applications require specific requirements, which is why we offer a diverse selection of sizes, materials, and configurations to cater to your unique needs.

Additionally, our team is equipped to provide customised solutions, ensuring that our valves are tailored precisely to meet your specific demands. Whether you require standard options or bespoke designs, our valves are built to deliver optimal performance and enhance the efficiency of your operations.

Forgings that exceed expectations: Top-quality strength and precision

Our manufacturing capabilities encompass a wide range of products designed to cater to various industrial needs. We specialise in producing Weld Neck, Blind, Slip-on, Socket Weld Neck, Reducer, Lap Joint, and Threaded flanges, offering versatility and flexibility in piping systems. Additionally, we manufacture Spectacle Blinds and Spacers & Paddles, which provide effective flow control and maintenance solutions. Our product range extends beyond flanges, including other components like Self-Reinforced Nozzles, Ring-Joint Gaskets, Stub Ends, Flushing Rings, and Tube Sheets.

Furthermore, we offer the advantage of customisation, allowing our customers to select different materials based on their specific requirements. Our available materials include Carbon Steel (such as ASTM A105, SA 350 LF2 Cl.1, 2, SA 350 LF3 Cl.1, 2, C22.8, ST37.2), Stainless Steel (such as 304, 304L, 316, 316L, 410, 321, Duplex F51, 53 & 55), Alloy Steel (such as F5, F11, F22, F91), as well as Inconel and Monel alloys. This extensive range of materials ensures that we can deliver products tailored to meet the diverse needs of our customers across various industries.

Accurate flow measurement solutions for every industry

We offer a comprehensive range of flow measurement products designed to provide accurate and reliable measurements in various applications. Our product lineup includes Orifice Plates, Meter Runs, Venturis, Averaging Pitot Tubes, Wedge Flow Meters, V-Cone Meters, and Magnetic Flow Meters.

Our range of flow measurement products finds application in a wide array of industries and scenarios. Orifice Plates, Restriction Orifices, and Orifice Meter Runs are commonly used in oil and gas, chemical, and petrochemical industries for accurate measurement and control of fluid flow rates.

Certified flow calibration services: Ensuring accuracy and compliance

We offer a comprehensive flow calibration service for all flow measurement products, ours and everyone else’s as well. Our experienced team and completely automated flow lab, and adherence to international standards ensure accurate and reliable calibration. With our calibration service, customers can maintain optimal performance, accuracy, and industry compliance. Our flow calibration service supports operational efficiency and quality assurance needs.

Innovative instrumentation for accurate measurements and control

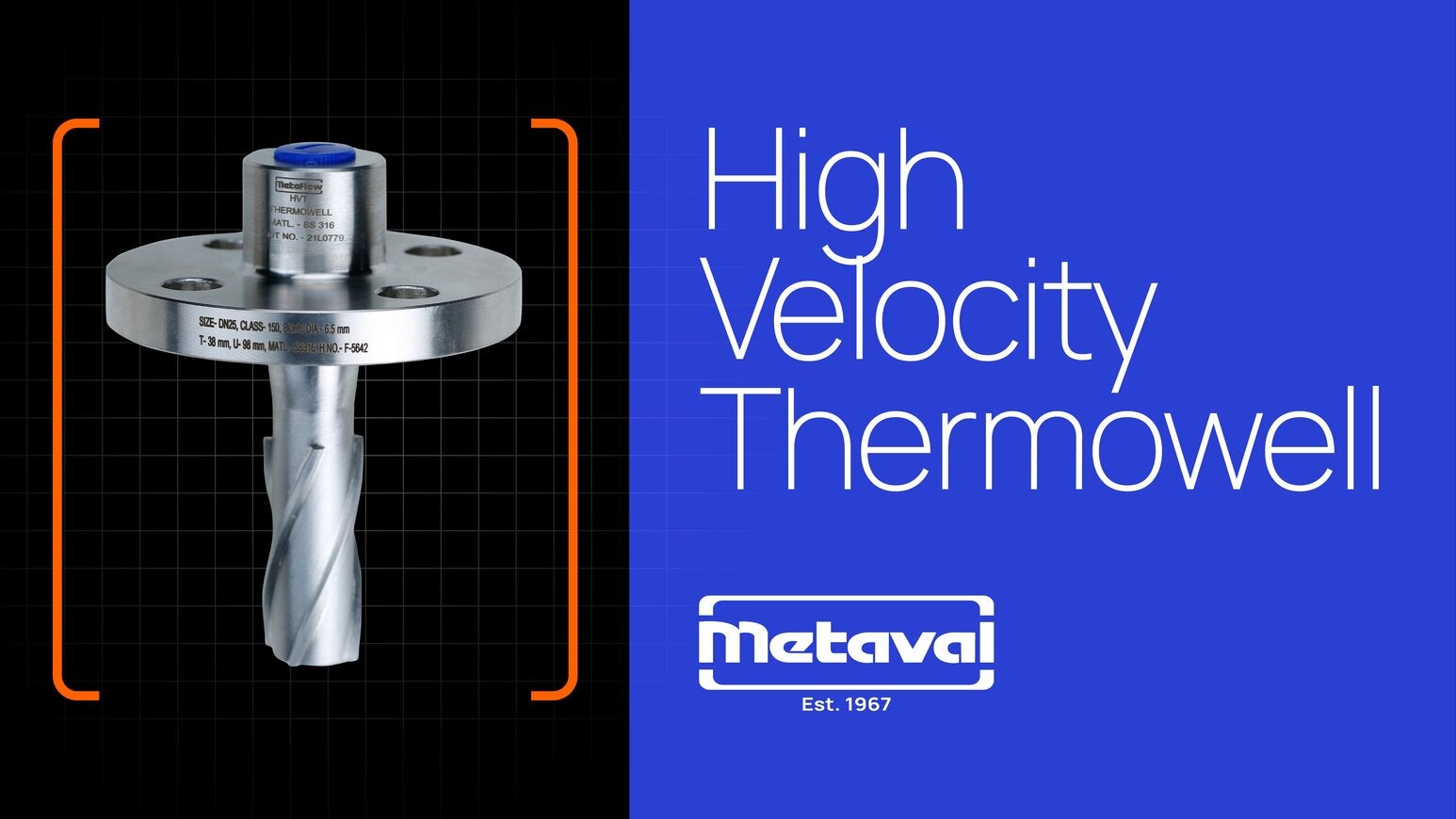

Our instrumentation division offers a diverse portfolio of products designed to meet various industrial needs. Our range includes Gauges to measure pressure, differential pressure and temperature, RTDs and Thermowells for temperature sensing and protection, Needle Valves and Pressure Gauge Valves for precise flow and pressure control and a selection of two-Valve, three-Valve, and five-Valve Manifolds for efficient instrument mounting and calibration. Additionally, we provide Gauges for accurate pressure measurement and a comprehensive range of Fittings to ensure secure and leak-free connections. With our instrumentation products, customers can rely on quality, precision, and durability to meet their measurement and control requirements in a wide range of industries.

We provide high-quality, customisable products that meet industry standards. Our fast turnaround time ensures timely delivery. With over 55+ years of expertise, we are leaders in the pipeline industry. Our competitive pricing maintains quality. Our exceptional customer service promptly addresses your queries and concerns. We hold ISO 9001:2015, 14001:2015, 45001:2018, PED certifications. Our ILAC-MRA/NABL certified Flow calibration lab guarantees accurate testing. Our in-house ASNT NDT Level III qualified personnel to ensure top-notch product quality. With 500+ worldwide clients and exports to 40+ countries, our products are globally trusted. Our headquarters in Australia, India, and UAE make us accessible to customers worldwide.

Our commitment to innovation and customisation means that we can tailor our products to meet the specific needs of our clients. We understand that every project is unique, and we work closely with our customers to deliver solutions that meet their exact requirements.

At our core, we believe that quality, innovation, and customer satisfaction are the keys to our success. We strive to build long-lasting relationships with our customers, providing exceptional service and support at every stage of the process.