Co.L.Mar is a specialist provider of acoustic subsea leak detection equipment. One of the company’s most recent and featured products is the underwater acoustic hydrophone, which allows for the effective detection of sound propagation in a liquid setting.

The company has been operating in the marine industry since 1982 and is experienced in acoustic engineering and geophysical investigations. Co.L.Mar is certified ISO 9000 – 2015.

Subsea leak detection systems for pipelines and subsea installations

Co.L.Mar. has released an acoustic subsea leak detection system ALD® (acoustic leak detector) which is able to locate very small leaks on the sea line even in extremely hard environmental conditions. After the first leak detection, back in 1998, the technology and the relative service have been developed for many years and an international patent has been obtained.

It is currently one of the fastest, most accurate and reliable methods for sea line leak inspection, especially when an emergency occurs. We are an international leader in this specialist area thanks to our decades of experience and history of delivering proven leak-detection solutions.

Since 2017, the ALD® technology has been qualified by DNV ‘for locating leaks in subsea pipelines and installations’. Our products, such as the underwater acoustic hydrophone for offshore applications, provide opportunities for a variety of applications that require subsea detection.

In the many offshore inspection projects we have worked on worldwide, we have been able to detect leaks as small as 0.04lt/minute.

Underwater pipeline leak inspection

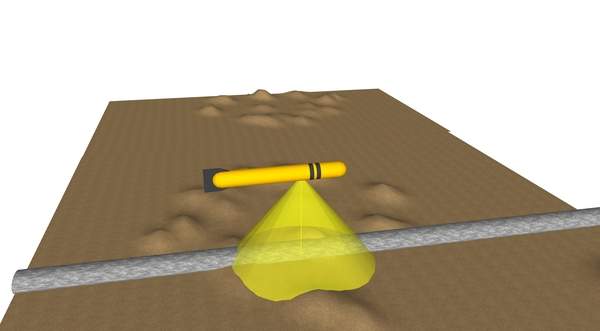

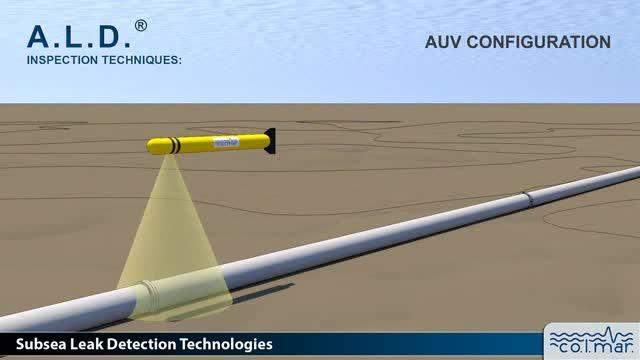

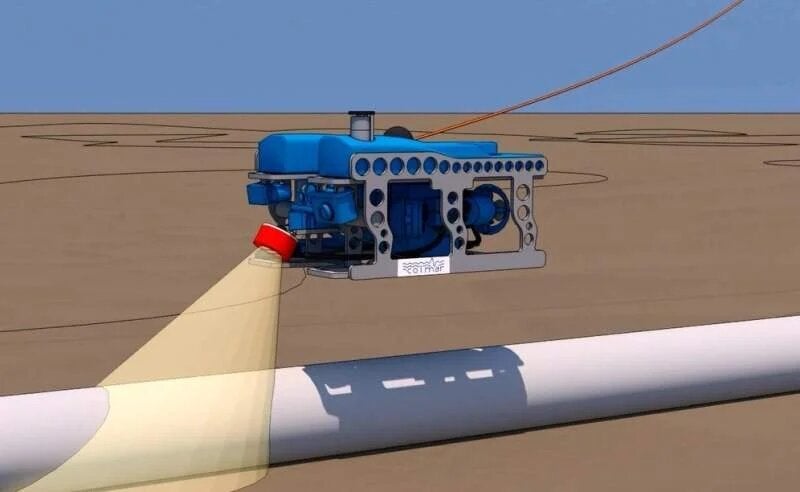

The ALD® underwater pipeline leak detection system features an underwater sensor that collects acoustic data as it scans the pipeline. The acoustic data is transferred online to an onboard receiver, then to a PC, where it is analysed, displayed and recorded by proprietary software.

Compared with other leak detection techniques, ALD® has the following advantages:

- Not affected by current, turbidity or pipeline burial

- No need to stop production

- High sensitivity for small leak detection

- Reliability: as of May 2015, 100% rate of success

- Rapidity: fast mobilisation worldwide

- Zero environmental impact

- ROV, TOWED, DIVER, AUV inspection modes available

- We served SAIPEM, ExxonMobil, McDermott, SHELL, BP, PETRONAS, TOTAL, TECHNIP, BJ Services, FUGRO and HORIZON

Underwater leak detection and inspection techniques

During years of development, different underwater leak detection and inspection techniques have been defined:

- ROV inspection – the sensor is installed on the vehicle, which follows the line at a speed of about 0.7kts

- TOWED FISH – the sensor, in a ‘fish’ configuration, is towed by a vessel along the pipeline track

- DIVER – the handheld sensor configuration is driven by a diver (suitable for flange inspections)

- AUV – a special version of ALD® can be easily fitted into any AUV payload

- VERTICAL DEPLOYMENT – the sensor is lowered from the boat in a line kept vertically by ballasts

Additional sensors integrated into the main system are available depending on the cases:

- Dye detectors

- Hydrocarbon detectors

- Methane detector

- Bubble detectors

25 years experience in subsea leak detection

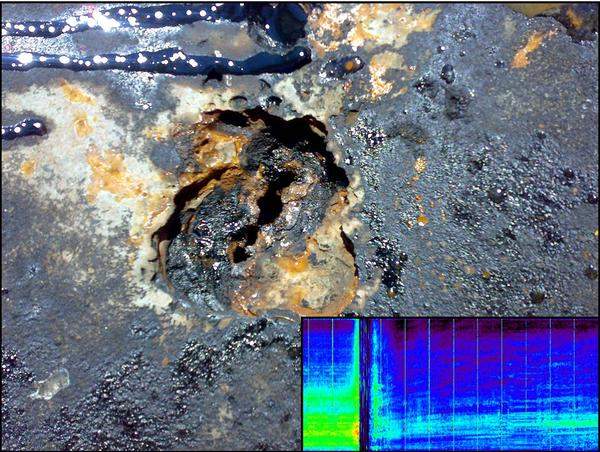

Colmar is probably the company that has detected the largest number of leaks in subsea installation, in 2023 thus number reached the value of 60. This is very large considering how rare is a leak event.

We have detected leaks worldwide, from the Caspian Sea to Borneo, from the USA to China and West Africa. We have been working under the ice or over 2.000m depth.

We have detected leaks on many different structures including:

- Oil, water and gas pipelines

- Hydraulic circuits

- FJ weld, longitudinal weld

- Buried pipelines

- Flanges

- Valves

- Umbilicals

- Umbilical connectors

- Riser

- Clamps

- Wellhead

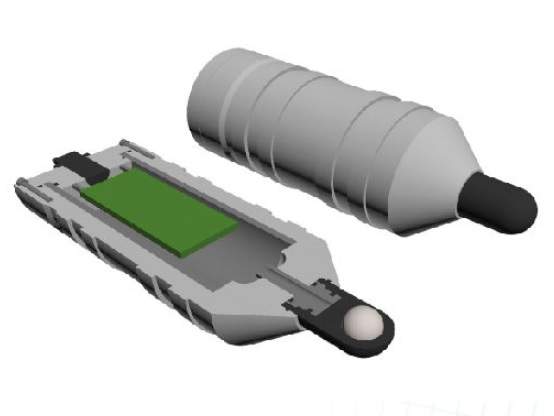

Underwater Acoustic Hydrophone

One of the most featured products by Co.L.Mar is the underwater acoustic hydrophone, which essentially refers to the study of acoustic waves in liquid environments and relates to the top-quality subsea detection services that the company already provides.

Designed to be either passive or active sensors according to the client’s application needs, the underwater acoustic hydrophone basically functions as a technology dependent on their intrinsic noise as well as the sea noise level. This allows the hydrophones to be versatile and can be applied explicitly to the oil and gas sector for offshore applications as they can be used both for shallower waters and deep water environments.

Clients will be specifically drawn to the customised nature of the hydrophones, their precision when it comes to noise detection, and their widespread application for a variety of subsea projects, which benefit from Co.L.Mar’s patented Acoustic Leak Detector technologies for subsea leak detection.

Hydrophones vary from low-noise and omnidirectional ones to digital hydrophones and many more.

ALD® as leak contingency plan during hydrotest

During the hydrotest of subsea installation, a leak contingency plan has to be put in place. This traditionally consists in injecting fluorescine or other kinds of dye and then proceeding with a visual inspection if required.

But in this case, very often the visual inspection fails because leaks on new installations are typically very small (FJ solder crack or leaking flange) and spotting any sign of dye became impossible. Not to mention if visibility is poor or some current burial is present. As a consequence, we are often called out on a very urgent base after the failure of the hydrotest of the traditional visual inspection.

For this reason, many clients contract us to standby on-site during any hydrotest so that, with a small cost they can have the best leak detection service guaranteed in case of need.

Also, dyes are pollutants and in many areas of the world are interdicted, while ALD has zero environmental impact.

So we can provide a more effective and environmentally friendly leak contingency plan during pre-commissioning.

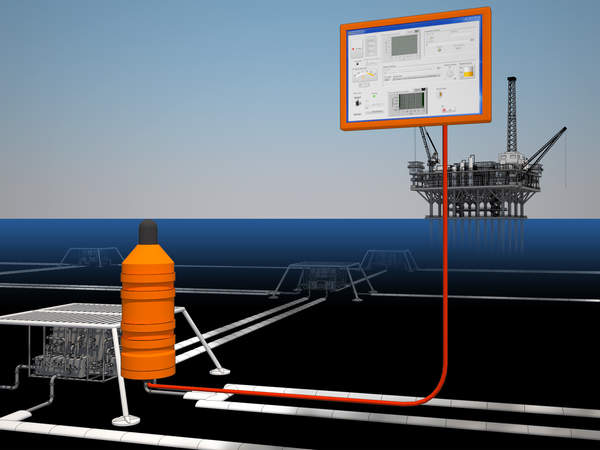

ALM acoustic leak monitoring of subsea installation

On the base of the experience gained in subsea leak inspection, we have recently developed a system for permanent monitoring of the most critical areas of subsea installation: manifolds, wellheads, valves, etc.

The system is composed of one of the more intelligent sensors to be installed subsea and of a surface station for settings and alarm generation. The subsea units are designed for a 25-year life expectancy with no maintenance and an operating depth of 3,500m.