From fuels and lubricants to asphalt, bitumen, plastics, and polymers, petroleum products are essential throughout the world. Anton Paar has been offering outstanding analytical solutions to companies in this industry for decades. We have a wide range of instruments to support clients in increasing their efficiency and lowering waste across all upstream, midstream, and downstream activities.

Enhanced crude oil analysis

Anton Paar offers solutions for measuring the density, viscosity, flash point, rheological behaviour, salinity, and refractive index of crude oil, as well as solutions for digesting petroleum samples for subsequent trace analysis.

The instruments are used at many points during oil recovery, refining, and transportation. The refining process is especially sensitive to changes in the crude oil composition and has to be monitored constantly so that immediate reactions to any changes are possible and by-products can be detected. Anton Paar solutions for crude oil analysis help customers control and optimise production with reliable and accurate measurements.

For example, Anton Paar Viscometers can be used to optimise the viscosity of your drilling fluid and reduce fluid availability risks or problems and costs associated with excess fluid disposal.

Our particle size analyzers will enable clients to control mud systems and detect LGS in drilling muds. During oil transportation, Anton Paar’s highly precise density meters are able to detect differences in oil products within the shortest time.

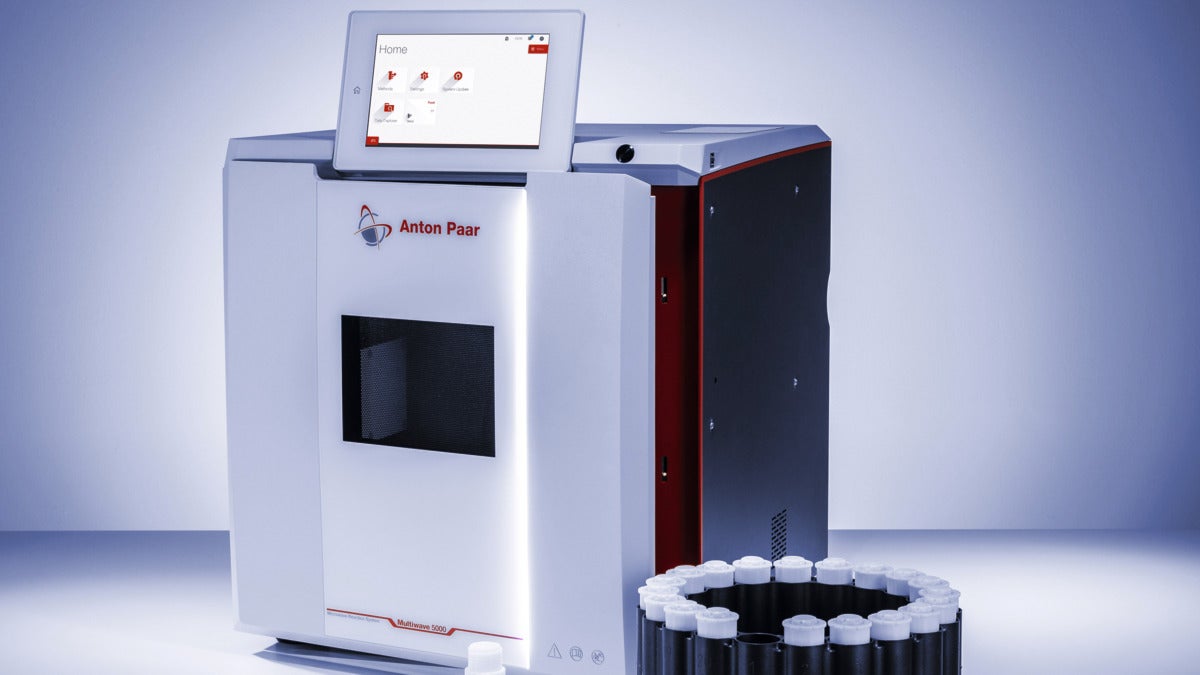

Whenever there is a need to characterise crude oil for classification and quality control, Anton Paar’s microwave-based sample preparation instruments digest crude oils in the quality needed for modern measuring techniques such as ICP-OES or ICP-MS to determine even low limits of the available trace elements.

Increased productivity and maximised return through fuel analysis

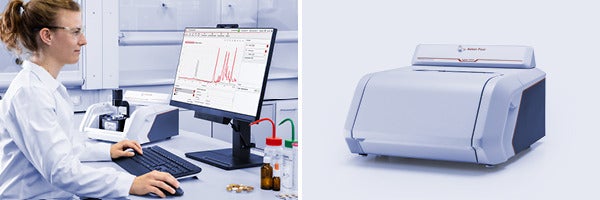

The analysis of fuels calls for robust and accurate measurement solutions. Anton Paar’s instruments provide process and laboratory measurements to identify incoming raw material, monitor production processes, or undertake fuel quality testing of final products such as diesel, ethanol, jet fuel, fuel oil, automotive gasoline, kerosene, biofuels, synthetic fuels, bunker oils, and other fuels.

Parameters such as density, viscosity, distillation behaviour, flash and fire point, rheological behaviour, and oxidation stability can be determined by Anton Paar devices according to governmental and environmental regulations such as ASTM, EN, and ISO.

For example, the Diana 700 can help ensure that incoming crude oil keeps flowing as it should and that the additives you use have the right composition when delivered. Our density meters such as the DMA 4500 and the handheld DMA35 will test the density and quality of your fuel.

The RapidOxy 100 will evaluate the client’s fuel stability and the Anton Paar GUM tester will test the gum content of fuels. The PNR12 measures consistency. ABA 500 is an ideal solution for automatic high-precision flash point testing in the petroleum, chemical and test laboratories according to EN ISO 13736, EN ISO 1516, EN ISO 1523, IP 491, and IP 492.

Get the correct stability and consistency of asphalt and bitumen

Analysis of asphalt and bitumen and their additives at the refinery ensures that they meet the specifications. Anton Paar’s measuring instruments and dedicated asphalt testing solutions deliver valuable insights into material properties which affect the processing of asphalt and bitumen such as long-term stability and consistency, as well as behaviour in storage and during transportation. The right measuring instruments optimise customers’ products so they withstand all environmental conditions.

For example, the BPA 5 is the automatic breaking point tester that determines the brittle behaviour of bitumen at low temperatures. The Dynamic shear rheometers (DSR) SmartPave allows precise measurements on asphalt binder and bitumen for ultimate quality control. The PNR12 measures bitumen consistency. More specifically, the PNR 12 measures the resistance material provides against being pierced by a specifically shaped test body.

Determining the low-temperature, low-shear-rate viscosity of lubricants

The low-temperature viscosity of hydraulic fluids such as automatic transmission fluids, gear oils, and other lubricants is important for the proper operation of mechanical devices. Anton Paar’s rotational viscometers allow clients to analyse an oil’s lubrication behaviour to guarantee the proper operation of mechanical devices at low temperatures.

Fully automatic measurement methods according to common standards are implemented in the software of the viscometers (including the ViscoQC). Thanks to a powerful air-cooled Peltier temperature device, the measurement is fast, accurate, and reliable. You do not need a PC as the temperature device is directly controlled by the viscometer for the greatest ease of use.

Measuring the fuel’s kinematic viscosity

In addition to kinematic viscosity and density according to ASTM D7042 and D4052, Anton Paar’s SVM 3001 Cold Properties also simultaneously determines the Cloud point of diesel fuel thanks to its built-in optical cell.

In order to satisfy various specifications as defined by ASTM D975, ASTM D6751, ASTM D7467, EN 590, EN 14214, EN 16734, EN 16709 and others. SVM 3001 Cold Properties provides kinematic viscosity, density and the Cloud point in one go as a scan. Measuring kinematic viscosity at -20°C does not require external counter-cooling equipment.

About Anton Paar

Anton Paar is based in Graz, Austria, and employs more than 4,000 people in total. We operate eight other producing subsidiaries and 35 sales divisions worldwide.

The company’s core competence, high-precision production, combined with its close contact with the scientific community, form the basis for the quality of its instruments.

Anton Paar is owned by the charitable Santner Foundation.