Offspring International Limited (OIL) is a leading supplier of single point and deepwater mooring systems, offloading hoses, marine breakaway couplings, engineered ropes and navigational moorings.

Based in Birmingham, UK, and with a subsidiary office in Laguna Hills, California, US, OIL is a dedicated team of mooring professionals with over 100 years’ experience in offshore mooring. OIL employees are active members of the Oil Companies International Marine Forum (OCIMF), where the company has contributed to single-point mooring (SPM) best practice. OIL is also represented on many oil and gas industry joint industry projects’ (JIPs) deepwater mooring committees.

OIL is the exclusive worldwide agent for Lankhorst Ropes Offshore Division (part of WireCo WorldGroup), and is the international agent for MIB Italiana’s MIBreak marine breakaway couplings and EMSTEC GmbH offloading hoses.

OCIMF-compliant single-point mooring systems

OIL supplies a range of SPM and tandem offtake mooring systems following the OCIMF 2007 "Recommendations for Equipment Employed in the Bow Mooring of Conventional Tankers at Single Point Moorings", including single or dual hawser configuration, single leg-type mooring hawser and grommet-type mooring hawser manufactured and supplied in strict accordance with the OCIMF 2000 ‘Guidelines for the Purchasing and Testing of SPM Hawsers’.

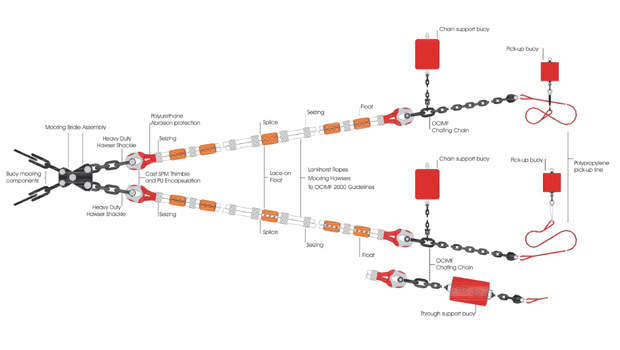

Chains, ropes, buoys and other SPM products

All OIL SPM systems and products offer outstanding operational performance, reliability and safety, and include chafe chains, mooring hawsers, pick-up and messenger ropes, support buoys, shackles, associated fittings and load-monitoring equipment. In addition, OIL is able to supply MIBreak marine breakaway couplings and floating, submarine and catenary hoses in accordance with OCIMF requirements.

MIBreak marine breakaway couplings

MIBreak breakaway couplings are designed to minimise the effect of tanker breakout and internal pressure surge events. Its next-generation rapid response, petal valve design minimises oil spills, yet is easy to reset on-site, reducing terminal downtime following an incident.

MIBreak features unique on-site reassembly after activation, enabling the MIBreak to be quickly and easily put back into service. There is no need to return the coupling to MIB to be reset. Moreover, on-site preventative maintenance by trained engineers ensures longevity of coupling service life. MIBreak is maintenance free for 5 years and designed for a 20-year life subject to periodic maintenance.

Single and double carcass offloading hoses

Offspring International is able to supply a full range of floating, submarine and catenary hoses in accordance with OCIMF requirements.

Deepwater polyester rope mooring systems

OIL offers deepwater mooring systems for floating production platforms including spars, FPSOs and FPUs using high-performance ropes from Lankhorst Ropes, the world’s leading supplier of deepwater polyester rope-mooring systems. Lankhorst Ropes’ range of deepwater mooring products includes GAMA 98® polyester rope tethers, Moduline® polyester ropes and GAMA 98® rope made with DYNEEMA®.

Major deepwater mooring projects handled by OIL include: Thunder Hawk DeepDraft Semi, Tahiti Spar Platform, the first FPSO deepwater mooring in the Gulf of Mexico Cascade-Chinook FPSO, and Lucius and Heidelberg Spar platforms.

Fibre rope connectors for MODU deepwater mooring

Offspring International is a joint developer of the innovative LankoFirst range of deepwater fibre connectors for rope to rope, wire or chain connections on mobile drilling units (MODUs). In place of a large spliced soft eye, normally used with H-link and shackle connections, the LankoFirst uses a sub-connector Donut that is integrated into the rope termination during manufacture. This innovative and smaller donut splice is much easier to handle offshore.

The LankoFirst connector can be assembled in just 15 minutes, compared with at least an hour and 15 minutes for a traditional shackle. LankoFirst only requires two people for assembly compared to three for a traditional shackle, reducing the number of people required on deck during hazardous line make-up operations.

LankoFirst gives naval architects and installation contractors a dedicated deepwater fibre mooring connector that is smaller, lighter, stronger and more efficient than current plate links and thimbles, for the same minimum breaking load (MBL).

Industry leading rope test and SPM manufacturing facilities

Lankhorst deepwater mooring ropes and SPM hawsers are manufactured in a purpose-built factory at Viana do Castello, on the coast north of Porto, Portugal. The factory covers 3,600m² production facilities together with a 2,400m² storage area. In addition to rope production machinery, it includes a large SPM make-up and storage area reflecting the factory’s increased SPM production capacity.

Lankhorst Ropes has invested €2M in a synthetic fibre rope test machine that enables OIL to conduct ‘what if’ mooring scenarios, simulating the effects of storms and hurricanes on deepwater mooring lines. It can also be used to test the mechanical performance and fatigue behaviour for new materials and rope constructions for deepwater mooring and SPM systems.

ISO 9001-compliant mooring system supplier

In line with its commitment to offer fit-for-purpose mooring systems, OIL is compliant with ISO 9001-2008 and other industry-related quality management systems and all relevant safety and environmental standards. Additionally, all equipment supplied by OIL is approved by the leading classification societies and supplied with the appropriate certification.