DSM Dyneema is the inventor and manufacturer of ultra-high molecular weight polyethylene (UHMWPE) fibre branded as Dyneema®, the world’s strongest fibre™.

Dyneema® offers maximum strength combined with minimum weight. Ropes made with Dyneema® are far lighter and much safer than steel wire rope traditionally used in offshore applications. They also out-perform ropes made from any other type of synthetic fibre. Ropes with Dyneema® are now used in a wide range of applications in the offshore industry. They are easy to handle, exhibit excellent stiffness and high-resistance to cyclic fatigue, abrasion and attack from the elements.

Mooring for offshore production

Permanent mooring lines made with Dyneema® Max Technology ensure safe station-keeping even in ultra-deep water. Dyneema® Max Technology enables stiffer mooring lines, providing more freedom in mooring and riser design. Lines are 70% lighter than polyester lines, they are weightless in water, and 30% thinner, so installation can be carried out quickly and safely, and transport vessels can be downsized. All this can accelerate time to first oil.

Ropes made with Dyneema® also provide the most reliable temporary solution when wire and chain mooring systems are damaged and need backup.

MODU and barge mooring

Operators of mobile offshore drilling units (MODU) and barges carrying out dredging or pipe installation need improved ropes. Waters are deeper and barges are repositioned more often, so ropes have to be strong but light.

Ropes made with Dyneema® SK78 are thinner than polyester and significantly lighter than steel wire rope. Time taken to install lines in pre-set MODU mooring systems is 40% less than with equivalent polyester ropes, and up to three times more rope can be rolled onto reels.

Deepwater installations

From suction piles to massive subsea templates, lines made with Dyneema® are the ideal choice to push boundaries in deploying and retrieving subsea installation. In ultra-deep subsea fields, costs and complications of working with steel wire rope become virtually unbearable.

Ropes with Dyneema® float in water, adding no weight to a payload at any depth. This is why they can be found in the deepest offshore projects in the world.

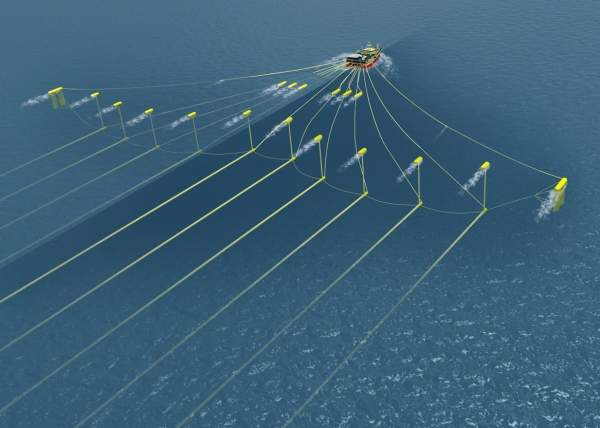

Seismic lines

Seismic lines made with Dyneema® outperform traditional alternatives in every way. Dyneema® SK78 fibre has outstanding breaking strength, reliability and endurance. Compared with alternatives, these ropes allow more precise seismic sensor positioning thanks to their lower and predictable elongation. Their exceptional abrasion resistance provides long lifetime, they create lower drag through the water, and the risk of ‘snapback’ in the event of a breakage is extremely low, increasing crew safety.

Heavy lift slings

Dyneema® fibre is seven times stronger than steel according to each unit weight, so slings made with Dyneema® can have exactly the same strength as a steel wire sling at the same diameter, at a fraction of the weight. Crews can handle them more quickly and safely, and this can be crucial when working in offshore conditions or when completing an operation before a weather window starts to close.

Advanced technologies

DSM Dyneema continues to make significant progress in the technologies behind Dyneema® fibre. Dyneema® Max Technology rewrites the rules regarding the capabilities of synthetic ropes in deep water permanent moorings. It enables the production of ropes that are not only light and strong, but almost completely resistant to creep.

Dyneema® XBO Technology has been specially developed to deliver bending performance superior to that of any other synthetic fibre. DSM Dyneema’s most recent innovation, Dyneema® SK99, is the strongest Dyneema® fibre ever developed, delivering the highest strength/weight and lowest rope diameter for a given strength.