Balltec designs and manufactures high load and intensity mechanical connectors for applications in the oil and gas and renewables industries. Core products include tools for mooring, pipeline recovery and heavy lifting. Balltec is currently developing weldless pipe connectors, driverless bend stiffener connectors and drill slip handling tools.

Balltec’s engineering experience can be employed for the design and manufacture of larger bespoke projects. The company is fully equipped to take on complex heavy engineering at our 75,000ft² workshop facilities.

The scope of our services and supply covers:

- Subsea mooring connectors

- Pipeline contingency tools

- Subsea installation tools

- Subsea abandonment and recovery tools

- Subsea deployment and recovery tools

- Mechanical handling tools

- Tube and hydraulic connectors

- In-house capabilities

- Design, manufacture and testing

- Consultancy services

Permanent and temporary subsea mooring connectors

Balltec’s MoorLOK™ is the world’s only patented ball-and-taper subsea mooring connector. The MoorLOK system is designed for the permanent and temporary mooring of all floating structures including FPSOs, drill ships, spars and tension leg platforms. The MoorLOK is built on 30 years of pioneering ball and taper expertise, resulting in the most reliable and advanced connector on the market. Balltec has established a 100% failure-free track record that cannot be equalled. All MoorLOK load-bearing components are manufactured from steel with a proprietary grade of F22. This is stronger and less brittle than other components on the market.

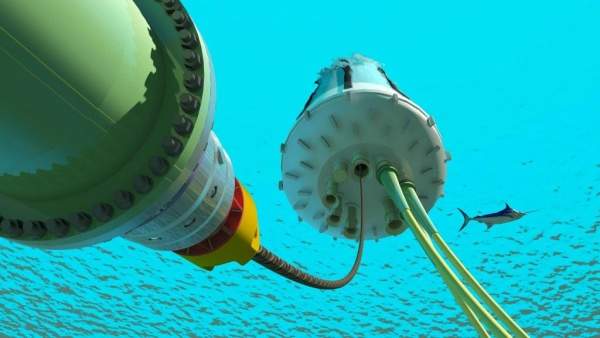

The MoorLOK is the world’s only ROV-less connection method. Its smaller, compact design does not compromise on robustness or strength. The TripLOK™ triple-locking mechanism remains failsafe even during zero loading and inversion, making the MoorLOK the most innovative and dependable mooring connector on the market.

Pipeline abandonment and recovery tools

Balltec’s PipeLOK™ fleet is the world’s largest and most technologically advanced collection of pipeline abandonment and recovery tools in the world. Stock tools of every variation range from 3in to 48in for all pipe sizes. The tools are engineered to provide greater reusability over a broad range of internal pipe diameters. They can be supplied with or without seals and dewatering capabilities with pig catchers.

The quality engineering of the PipeLOK ensures a solid design that can be used for numerous lifts and recoveries with a safe working load of up to 1,200t and no water-depth limitations. Bespoke PipeLOK tools can be manufactured to suit your project’s requirements and additional features can be engineered to find a solution to your problem. The PipeLOK tools have been proven with a 100% track record over multiple internal pipeline lifting projects.

Heavy lifting tools

Balltec LiftLOK™ heavy lifting tools provide a simple, robust, high-capacity method for connecting and disconnecting heavy loads to and from lifting devices. As purely mechanical gripping devices that require minimum ROV intervention, LiftLOK products are ideally suited for the deployment and retrieval of equipment to and from the ocean floor.

The lighter, more compact LiftLOK tool can be engineered to any load capacity with bespoke tools designed for any unique application. The LiftLOK has a failsafe design where the tool can only be released under zero-load conditions, ensuring that there is no risk of accidental damage.

Hand-held coiled tubing handling tools

The Balltec CoilLOK™ is available in sizes ranging from 1in to 3.75in. It has been engineered to gain the maximum safe working load (SWL) while remaining compact enough for use through injector heads and light enough for simple hand-held operation.

CoilLOK tools can be manufactured with a range of interfaces including pad eye, clevis head and wire adaptors as well as custom-made options for alternative applications.

Bend stiffener connectors

The BendLOK™ bend stiffener connector offers a secure and robust permanent mechanical connection between bend stiffeners and I or J tubes on platforms, FPSOs and buoys. Its adaptable design provides flexibility to enable installation of various risers, umbilicals and end terminations. It allows fully automatic engagement and disconnection, without the need for divers or ROV intervention, and has a simple, maintenance-free female part connected to the FPSO or turrets.

Balltec has developed a riser pull-in tool to be used in conjunction with the BendLOK connector. This allows for an automatic release without the need for shear or tension pins or hydraulics. The same tool can also be adapted to function as an automatic BendLOK release system that securely retains the riser and male component during recovery.

Engineering services

Balltec has a team of dynamic and innovative engineers and designers with a vast knowledge of all aspects of the oil and gas industry. The engineering team is available as a solution-based service and has been responsible for the design and installation of hundreds of bespoke tools and projects across the world. The team works closely with clients and their sub-contractors to share, collaborate and innovate.

Balltec engineering is highly accomplished with subsea work. The team offers multi-disciplinary services in the development of conceptual projects, the design of custom tools, feasibility analyses and the implementation of sound-engineered solutions for the industry.