WDH Hydraulics designs and manufactures bespoke hydraulic cylinders for offshore platforms.

Using industry experts and by cooperating with its partner companies, WDH is able to provide a comprehensive service quickly, flexibly and efficiently.

The company understands the differences between various working environments, and engineers the most appropriate solution for the client’s application by matching their requirements with its own extensive experience.

Typical customers include offshore equipment builders, dredging companies and shipyards.

Customised hydraulic cylinders for the offshore industry

WDH Hydraulics manufactures custom-made products, which are often the result of an extensive, collaborative engineering process between the company and the client.

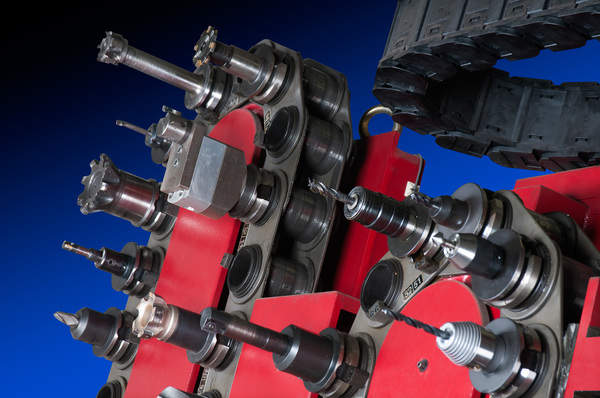

Typical products include:

- Hydraulics cylinders

- Turn transits

- Closing heads

- Piston accumulators

All products are engineered to perform under severe conditions and provide reliable power and safe controls for marine and offshore applications.

Cylinder maintenance and repair for marine structures

WDH Hydraulics fully understands that equipment downtime will have financial repercussions. Limiting downtime is therefore crucial in the company’s designs, as well as ensuring a quick turnaround in the event of a cylinder repair. In order to prevent future downtime, WDH often modifies the components as well.

The company has proven to be a reliable partner for professional industrial organisations, such as Huisman Equipment, Heerema and Boskalis. Short communication lines, quick decision-making and a good cooperation make WDH Hydraulics an extension of the client’s company.

Engineering design services

WDH’s engineering department’s broad knowledgebase and advanced computer-aided design (CAD) technology (Solid Works) ensures that staff can design the optimum solution effectively and efficiently.

The company fully understands the requirements of various important classification societies such as Lloyd’s, Veritas, DNV and ABS.

Quality management services

WDH Hydraulics’ quality management system has been successfully certified under lSO standard ISO 9001: 2008. This enables the company’s employees to focus on quality and continuous improvement. Certification for ISO 9001: 2015 is planned for early 2016.

The ISO 3834-2 standard is also in place, which ensures that WDH works in accordance with approved procedures and fully qualified welders under the supervision of a welding coordinator.

Equipment storage services

WDH Hydraulics stores customers’ spare cylinders and its extensive, in-house machine park is fully equipped to make, modify or repair other large equipment parts.