Sensima Inspection recently obtained a major contract from a leading Swiss power company to develop and implement an underwater scanning inspection system. The system will be used to automatically scan a 100m wide by 30m deep underwater grid protecting the intakes of hydro power turbines. About 500 scans are expected to be performed over a time period of three to five years.

Sensima Inspection formed a consortium together with partners to respond to the call for tender. The consortium has successfully demonstrated its capability to produce a system combining a durable mechanical scanning mechanism with a dedicated inspection device aimed at producing relevant maps of the grid condition. A key aspect of the project is the application of manufacturing and power generation industry standards into a civil engineering underwater infrastructure.

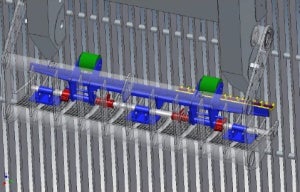

The system will be delivered in June 2014. The above figure illustrates the concept developed by the consortium. The 1.5m-long inspection system contains an array of eddy current probes which are scanned on the bars of the grid. The system is attached to a crane that is also used for other tasks.

With this project, the consortium positions itself as a major Swiss integrator for monitoring and inspection in harsh environments. The consortium is now actively seeking underwater monitoring and non-destructive testing (NDT) projects in the oil and gas industry.

Contact Details

Sensima Inspection

Mont Blanc Plaza

31 ave Mont Blanc

CH-1196 Gland

Switzerland

Tel: +41 22 364 49 20

Fax: +41 22 364 49 30

Email: info@sensima.ch

www.sensimainsp.com

Sensima Inspection is a technology company arising from the Swiss Federal Institute of Technology (EPFL), which develops advanced electro-magnetic solutions for NDT and quality control.

Sensima Inspection is a unique combination of the most advanced technologies including microelectronics design and a recognised expertise in NDT. Our innovative products are designed to improve performance, to reduce equipment size and weight, and to facilitate integration in and interfacing with your inspection systems.