Sensima Inspection is a technology company arising from the Swiss Federal Institute of Technology (EPFL), which develops advanced electro-magnetic solutions for non-destructive testing (NDT) and quality control.

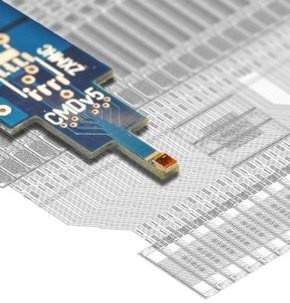

Sensima Inspection is a unique combination of the most advanced technologies including IC design and a recognised expertise in NDT. Our innovative products are designed to improve performance, to reduce equipment size and weight, and to facilitate integration in and interfacing with your inspection systems.

Ultraportable eddy current tester

Sensima’s ultraportable USB eddy current tester is one of the most compact of its category. Special care has been taken to ensure that the instrument is quickly set up and intuitive to use. It integrates advanced features such as multifrequency, multiplexing, probe identification and digital communication.

The tester is provided in an inspection kit containing all accessories necessary to perform an inspection, including the software, a probe and calibration notches machined into the casing wall.

Underwater eddy current tester

TThe underwater USB eddy current tester is a specialised version of the ultraportable eddy current tester designed for underwater inspections down to 1,000m. The unprecedented compactness and performance of this product match the demanding needs of professional underwater NDT companies. The tester can be directly attached to the divers gear and does not require additional communication modules even for long distances (1,000m).

The tester is designed to be connected to a probe operated underwater by a diver or an ROV on one side and to a computer located on surface on the other side. The surface operator has access to the data in real-time.

Sensima provides full solutions for probes, cables, UW monitor, and connectors, or is able to adapt the tester to your accessories.

ROV integration

Sensima’s compact eddy current technology is ideally suited to instrument an ROV, both for ground and submarine applications. Together with our partners, we can provide full solutions or customise your ROV for NDT applications.

Consultancy

Sensima’s team has acquired recognised experience in high-profile NDT projects for power generation and other large industries. Our skills cover R&D studies, inspection of complex geometries and instrumentation of automated inspection systems. Our laboratory is fully equipped to assess and optimise your EC NDT equipment and procedures.