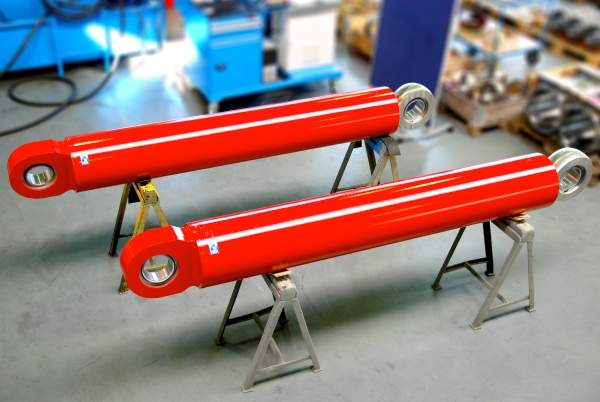

RUHFUS Systemhydraulik offers complete system engineering and turnkey package for oil and water hydraulics. We design, manufacture and supply special hydraulic cylinders, power packs and electrical control panels.

Our custom-designed hydraulic cylinders (servomotors), power units, electrical controls (PLC or relay-contactor based) and single parts are being used in demanding applications and harsh environments such as offshore, oil and gas, marine, naval, ship building, shipyard and dry docks, ports, salvaging, dredging, bridges and locks, hydropower and dam gates, water and wind turbines, mining, cement, lifting, presses, heavy machinery and others.

Applications and capacities

We have the capacity to produce long stroke hydraulic (and pneumatic) cylinders with an overall length of 20m, piston stroke range of up to 15m, piston diameter of up to 1,200mm, outer diameter of up to 2,000mm and total weight of up to 25t for:

- Riser tensioner

- Heave compensation

- Heavy lifting, marine-grade crane and hoist

- Submersible equipment, underwater machinery

- Linear motor, actuators, jacks

- Energy dissipation or storage (cylinder with integrated accumulators)

- Jack up, drilling rigs, platforms

- Pipe laying vessels, A-frames, salvaging

Our equipment displays a wide range of special features, including:

- Lightweight, high-pressure cylinders

- Stainless-steel and high strength material for parts or for complete cylinder

- Bearings in composite, bronze and stainless

- Hollow rods and telescopic cylinders

- Various safety and control valves

- Corrosion protection options (carbide, ceramic, nickel-chrome, chrome, laser cladding of super alloys)

- Various stroke measuring systems such as LPM, wire transducer, tempo sonic

Our cylinders are designed and produced to class requirements, such as:

- Det Norske Veritas – DNV

- Germanischer Lloyd – GL

- Lloyds Register of Shipping – Lloyd’s

- American Bureau of Shipping – ABS

- Bureau Veritas

Other services that we offer include:

- Maintenance, repair, upgrading, reconditioning of hydraulic cylinders

- Parts and spares, spare cylinder

- Parts for OEMs e.g. for hydraulic-driven solids pumps, for hydraulic hammers and so on

- General machining services ( turning, milling, deep hole drilling, honing, skiving and roller burnishing, grinding, polishing, welding, coating and cladding)

Technically-skilled and experienced engineering team

Our engineers work closely with your experts to develop cost-effective solutions and guarantee the highest quality. We design and manufacture complete hydraulic systems for various applications, and have collected considerable experience during the past decades. Our flexible team uses experience gained from our previous work to develop new solutions.

Quality management system

The documentation of processes, which had begun in 1981, was confirmed in 1996 by the Bureau Veritas International (BVQI) with the EN ISO 9001 Certification of Quality Management. We have had no non-conformities for the last 14 years, witnessed by semi-annually surveillance audits. Among others, we are certified by German Railway according to DIN EN 13261 and DB AG – BN 918 275 as well as AD 2000 and DIN EN ISO 3834-2 by TUV Rhineland.

Contact our local representatives or our head office in Neuss Germany for further information.