As a hydraulics specialist with a long-standing reputation for supplying solutions for mobile cranes, harbour cranes and hydromechanical engineering, Montanhydraulik has by now also successfully established itself as a system provider to the offshore sector. The engagement in this market segment could be significantly increased in the future thanks to Muns Techniek joining the group.

The product range includes differential, telescopic and synchronised cylinders as well as rotary actuators, piston accumulators, counter-balance lock valves and the designing and fabrication of complete hydraulic and electric drive systems. Modern controllers developed by Muns Techniek ensure smooth and precise coordination of all steering functions. All system components are controlled by local programmable logic controllers (PLCs), each inside a control cabinet, and if needed powered by soft starters. The control system and its components are designed for long operating periods and are thus correspondingly reliable and maintenance-free. Both companies aim to develop systems which are not only durable and loadable, but which also contribute in making processes economical, flexible, environmentally sustainable and completely controllable.

Equipped for special customer requirements

The requirements placed on Montanhydraulik have different focuses: weight optimisation, cost optimisation, fatigue strength, corrosion resistance and low maintenance. To fit the interfaces to customers’ machines and systems, our engineers also develop drive controls with highly complex control technology, integrated displacement measurement systems or special valves. The constantly increasing component and system requirements demand a detailed knowledge about the behaviour of components and materials as a prerequisite. Montanhydraulik completes this knowledge through continuous investment in research and development as well as several test bench investigations which comprise fatigue design appraisal and which also serve to research basic principles.

Montanhydraulik provides the following services and products:

- Differential cylinders (up to 800mm diameter and 21,000mm stroke)

- Telescopic cylinders with hydraulic retraction (up to 500mm diameter and 28,000mm stroke)

- Synchronised cylinders (up to 500mm diameter and 28,000mm stroke)

- Rotary actuators (up to 500 kilonewton metres)

- Piston accumulators (volume between 0.6l and 3,500l and either 160 bar, 240 bar or 400 bar)

- Hydraulic pump units

- Hydraulic oil tanks

- Manifold blocks

- Electrical control cabinets

- Soft starter boxes

- Control panels

- Sliding blocks

- Locking pins

- Cooling units

- Operating desk with HMI

- Multi-port swivels

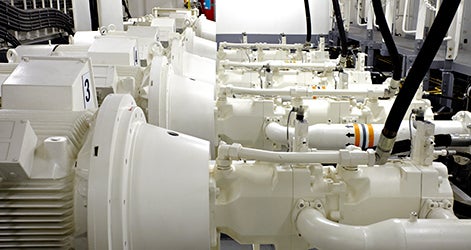

Jack-up vessel with a double-acting lifting system

The system technology of Muns Techniek, paired with Montanhydraulik’s tailor-made hydraulic cylinders, is successfully installed in the offshore systems of many renowned installation companies. The technology guarantees a safe stand in water depths of up to 50m for not only jack-up platforms such as Hochtief’s Odin and Thor, but also for superior systems like the jack-up vessel Vidar. This ship converts into a jack-up platform due to the hydraulic lowering of four movable legs 90m in length and 4.8m in diameter. The jack-up system can lift a total weight of 25,000t out of the water. It consists of 48 corrosion-resistant cylinders, the respective rig fixation systems and guide frames as well as the corresponding electrical control system.

The hydraulic construction is characterised by two mobile guide frames per leg, which are placed on top of each other. Their movement is regulated by means of a synchronous control unit. Muns Techniek developed the control system in order to ensure the synchronous lifting and lowering of the four legs by the necessary stroke, without the platform having to be stopped for the fixation procedure.