Trelleborg Offshore is a leading engineering company that specialises in the development of advanced high-integrity polymer and syntactic foam solutions to seal and protect critical applications, optimising performance in harsh marine environments.

Our cutting-edge innovations are designed to optimise the quality, safety and efficiency of clients’ operations across all segments of the oil and gas industry in a sustainable manner.

Subsea flowline protection for oil and gas projects

The increasing reliance on data and product transfer solutions within the offshore industry, and the need for these transfer networks to run through increasingly harsh environments, has led to a demand for advanced cable and flowline protection systems to safeguard against wear and abrasion.

Trelleborg’s innovative Uraduct® range has been specially designed to provide reliable, impact-resistant protection for a wide range of subsea flowline systems, including fibre-optic cables, power cables, umbilicals and hoses.

Our versatile cable protection products are available in various sizes and may be attached to the main pipeline using an optional clamp arrangement during installation to ensure the secondary lines are adequately supported between the surface and seabed.

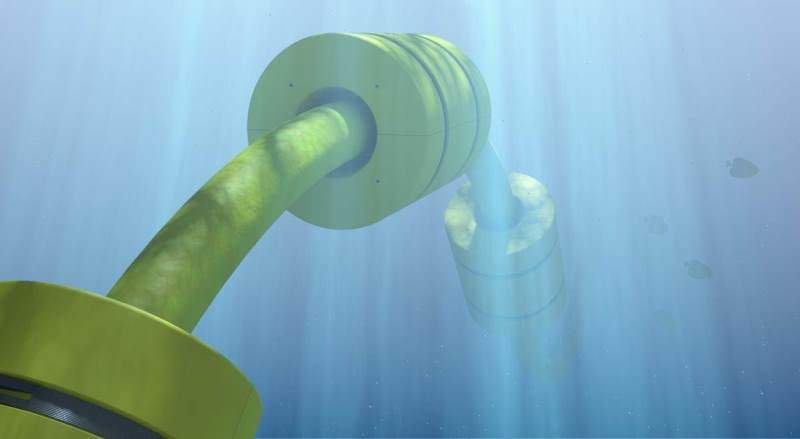

Bend control solutions for critical locations

When flexible tubular systems are connected to a structure, normal operational movement or the application of force during the installation procedure can lead to potential damage at the termination point.

Our advanced bend control solutions are intended to mitigate this damage. We provide a range of bend stiffeners and restrictors, as well as NjordGuard™ cable protection system that have been specially optimised for seismic, offshore and renewable industry applications.

Trelleborg’s NjordGuard™ for the renewable industry is fabricated from API 17L-certified Uraduct® materials and require minimal assembly. NjordGuard™ can also be easily installed and removed without the need for diver intervention or remote operating vehicles (ROVs).

Buoyancy systems for offshore applications

Floating productions in the oil & gas and renewables industries often feature pipelines such as flexible cables, risers and umbilicals that need to be held underwater in specific geometric configurations to prevent over-utilisation.

Trelleborg offers an array of standardised, distributed, and rotating buoyancy and buckling mitigation modules to provide vital stability during installation and operation. Trelleborg’s range of subsea buoyancy also includes riser towers, tether bases and midwater arches to ensure the highest possible degree of structural support for clients’ floating productions.

Trelleborg’s drill riser buoyancy solution provides buoyancy modules in order to reduce its weight in the water to a manageable amount. Trelleborg’s comprehensive range of drilling buoyancy solutions also includes helically grooved buoyancy for the drill risers, and repair solutions.

Flame-resistant materials for passive fire protection

Protecting on-site equipment and structures allows more time to evacuate personnel in the event of an accident, as well as giving fire services valuable time to control the situation.

Trelleborg’s FireStop™ material is able to significantly delay the escalation in temperature in steel structures and can be used in various topside applications to safeguard assets from fire, explosions, collisions and vibrations.

Trelleborg’s flexible piping system, Elastopipe™ is made of synthetic rubber and is approved for offshore deluge systems. This robust, low-maintenance solution requires no welding during installation and is available in a fire-resistant (FR) variation for freshwater and seawater applications, as well as a fire and oil resistant (FOR) versions for harsh environments involving hydrocarbons, additives, solvents, hydrogen sulphide and acids.

Furthermore, our hand-mounted FireNut™ system delivers powerful protection for bolted connections against jet and hydrocarbon fires for up to two hours, significantly prolonging the structural integrity of worksite structures in critical situations.

Thermal insulation coatings for offshore sites

Trelleborg’s range of Vikotherm™ insulation materials are designed to mitigate the gradual formation of hydrate plugs and wax build-up within offshore structures.

Trelleborg’s extensive portfolio of materials,ensure high-quality protection in accordance with clients’ individual project requirements, including rubber, silicone, epoxy syntactic foam, glass syntactic polyurethane and syntactic polypropylene tape, as well as a thermoplastics.

Trelleborg is able to deliver hassle-free on-site application of its corrosion treatments, thermal insulation and passive fire protection systems using the company’s Mobile Production Unit (MPU) coating facility.

Comprehensive solutions from downhole to topside for offshore industries

In addition to specialising in flowline protection, buoyancy control and fire safety solutions, Trelleborg’s solutions also covers:

- Clamping and topside solutions

- Riser ancillaries and protection

- ROV / AUV / HOV buoyancy systems

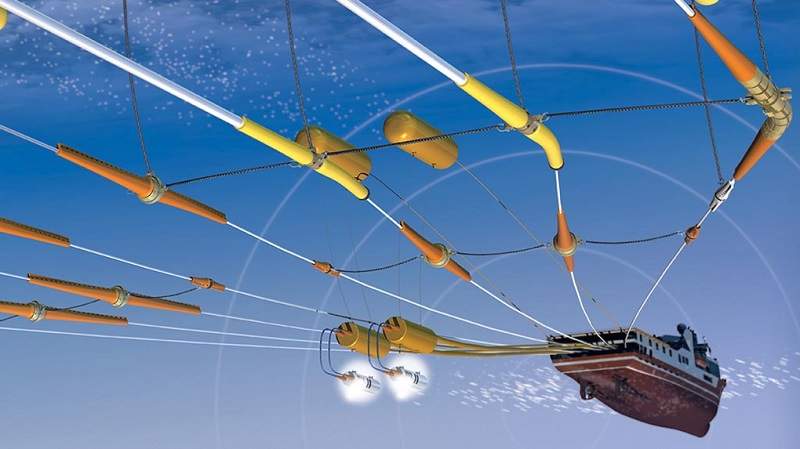

- Seismic cable handling

- Spill prevention

- Crushable foam wrap

- Towing ancillaries and attachments

- Riser ancillaries and protection