Favuseal offers superior, environmentally friendly fire protection solutions for glass-reinforced plastic / epoxy (GRP / GRE) piping, steel piping, fibre optics and power cables. Two of the company’s main products, the Favuseal fire barrier system (FFBS) and the Favuseal fire barrier system X3M (FFBS X3M), provide unprecedented passive fire protection up to 1,400°C. The products can come granulated or in tape roles of various widths, ensuring flexibility for extremely easy installation. FFBS and FFBS X3M are perfect solutions for both pipe and cable manufacturers and for existing installations in need of improvement.

Favuseal products are used worldwide and are thoroughly and independently tested in the most severe conditions. Due to its halogen and fibre-free nature and the absence of corrosive and toxic gases during its transformation, FFBS is very safe for installers and the surrounding environment.

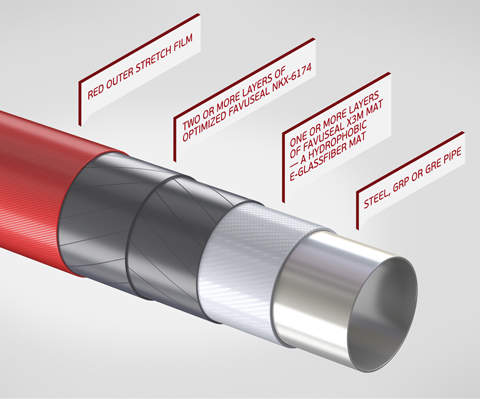

Polymer-based fire protection for GRE piping and cables

FFBS was introduced in 1988 for the protection of GRE piping in the offshore industry. In the 1980s, the novel use of composite piping materials like GRP/GRE opened the way for new technologies that are superior to steel in many respects, but are not tolerant to fire. FFBS is a solution to this problem, and is now successfully used in numerous oil and electrical installations, protecting power and communications cables.

FFBS, a rubber-like polymer-based passive fire protection product, fights extreme heat with a clever two-phase chemical system that results in ceramic formation. It combines two strongly endothermic processes in order to consume excessive heat in a safe and non-hazardous way.

The first phase takes place between 200°C and 250°C, in which crystal water is generated from OH groups in the fillers. A reaction requires a great amount of energy for H2O formation and this secures temperatures of 250°C to 300°C behind the barrier as long as the reaction is taking place.

The second transition phase takes place between 700°C and 800°C, and consists of the generation of cellular ceramics resulting from the oxidation of filler minerals which are also strongly endothermic. The formed ceramic is physically stable up to 1,500°C, creating a powerful insulator for your installation.

Green fire barrier solutions for a safer environment

Favuseal technology uses chemical reactions, but at the same time is eco-friendly and safe. It is halogen and fibre-free, has very low smoke emissions during transition and does not produce corrosive or toxic gases. After a fire, the waste created by the chemical reactions of FFBS is not dangerous and is disposable as regular waste. It does not require any special treatment, which can be the case with similar products. These features make FFBS safe for installers, passersby, firefighters and the surrounding environment.

Impact-resistant installation protection

The primary purpose of FFBS is, of course, to protect your installations from fire. But because FFBS has superior physical properties, it provides some added benefits too. FFBS is a non-rigid, somewhat-compressible, flexible and thin layer of thermoplastic compound. These properties make your composite installation much stronger and more resistant to impact. This saves valuable time and money in case of mishaps, where the outcome would usually demand repair.

Electrical cables protected with Favuseal technology are additionally protected from parallel arcs and heat deformation because of the added width and insulation of the cables with non-conductive FFBS. FFBS is also soft enough to allow cable pulling and bending without trouble or the necessity of any special high-cost cable-pulling equipment.

Easy installation fire protection system

FFBS is installed without mess, spills or expensive tools. Because it comes in two very flexible forms, it is extremely easy to use and apply. Wrap it around something, extrude it onto something, use it in injection moulding or compression moulding – the choice is yours. Favuseal is the world’s most versatile fire protection material.

Favuseal also provides expert technical support. The company’s experts will calculate the right dimension of the barrier for you, using a well-proven mathematical model. Favuseal also provides a comprehensive installation manual for even easier application of FFBS.

Thoroughly tested fire protection systems

A series of tests on FFBS-protected GRE pipes have demonstrated the system’s excellent properties as a fire barrier. Tests have been made in ovens, under jet-fire conditions and in simulated explosions. All tests were extremely successful and resulted in excellent outcomes. Some tests were witnessed by independent parties, such as Lloyds and DNV.

Global delivery

Favuseal can deliver FFBS and other products in any quantity all over the world at relatively short lead times. As a result of its ultimate versatility and adaptability, Favuseal technology can already be found on oil rigs and floating production storage and offloading (FPSO) vessels globally. Materials used in Favuseal’s solutions are suitable for all kinds of climates and temperatures. Ship, rig and building owners around the world trust Favuseal to protect their investments.