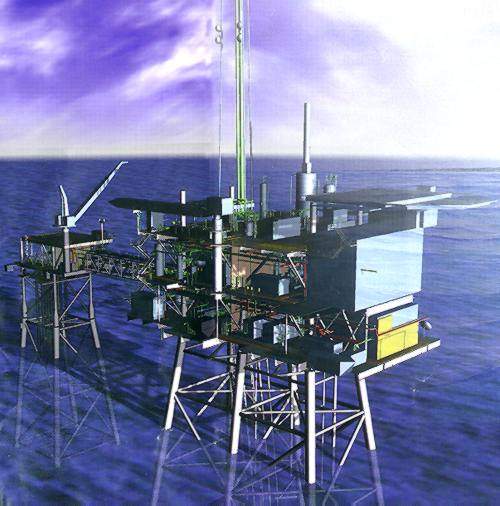

Burner Fire Control® JJM is an independent manufacturer of large-capacity and high-performance special hazards fire equipment and offshore heat suppression systems.

Manufactured systems consist of dry chemical powder (DCP) skid units, twin-agent skid units, as well as aqueous film-forming foam (AFFF) and compressed air foam systems. The company also provides related services to offer turnkey project capabilities and a full equipment lifecycle programme.

Offshore services comprise Water Curtain® rig cooling, pre-US Coast Guard (USCG) and Bureau of Safety and Environmental Enforcement (BSEE) inspections, as well as fire equipment and system inspections.

Burner Fire Control also provides a number of equipment lifecycle services such as design, engineering, repair, reconditioning, re-certification, spare parts procurement, rental, training and technical support.

Large-capacity fire suppression equipment

Burner Fire Control manufactures an extensive line of self-contained fire suppression systems. For the last 40 years, our portfolio equipment has been procured by more than 1,600 of the industry’s largest companies, spanning 26 countries worldwide. All equipment manufactured is designed, fabricated and assembled to withstand the most extreme conditions.

Special hazards fire equipment design

Burner holds a NICET level III certified systems designer on staff and with numerous completed projects worldwide, it has the capability to deliver turnkey customised solutions to fit any land or offshore project requirements.

Initial site surveys and inspections, design services, installation and refurbishment are all included in service designs.

Special hazards fire equipment manufacturing

Our manufacturing and assembly process has been field tested and proven for more than 40 years. The result is a range of high-quality equipment, using premium system components that have operated continuously in the harshest environments.

Fire equipment inspection and maintenance

Our maintenance and inspection capabilities have developed over years of experience in completing global projects for top companies. Burner’s teams have performed numerous land-based and offshore surveys on platforms, barges, marine vessels and LNG tankers.

Fire equipment testing and refurbishment

All newly built and refurbished systems go through a rigorous testing, inspection and re-certification process to ensure maximum integrity and reliability. Hydrostatic testing is required for all pressure vessels in accordance with ASME Code.

Burner specialises in the following fire suppression systems:

- CO2 fire suppression systems

- Dry chemical systems

- Dry powder system skids

- Twin-agent system skids

- Compressed air foam systems

- AFFF fire protection units

- Fire and gas detection systems

- Clean agent fire suppression

Land field and offshore platform maintenance services

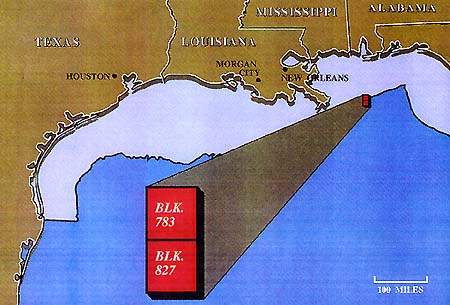

Burner also provides a comprehensive range of on-site maintenance services. With the capabilities from standard land applications to highly customised offshore solutions, the goal is to help our clients maximise asset up time and build a compliant safer working environment. Burner’s offshore platform maintenance programmes are used by the world’s top companies.

Burner’s memberships and certifications include DNVGL, ABS, UL, NAFED, NFPA, NICET, ASME and ISNetword.

Safety compliance and fire inspection services

Burner holds certifications by both American Bureau of Shipping (ABS) and Det Norske Veritas (DNV). Our management team has more than 100 years of combined experience in the fire protection industry and we ensure the maximum protection for your personnel and project assets.

Our experience in arrangement surveys, safety inspections, PPE sales, rental capabilities, as well as fire-fighting equipment inspections, design and manufacturing, have proven to provide the required resources to meet and exceed compliance and safety requirements.

We also perform pre-USCG surveys, BSEE inspections, fire equipment and safety inspections for countless major companies globally.