Mactech Offshore has introduced the revolutionary ROV (remotely operated vehicle) Diamond Wire Saw.

The ROV Diamond Wire Saw was designed to address economical efficiencies and advantages while focusing on personnel and environmental safety when cutting equipment for abandonment operations.

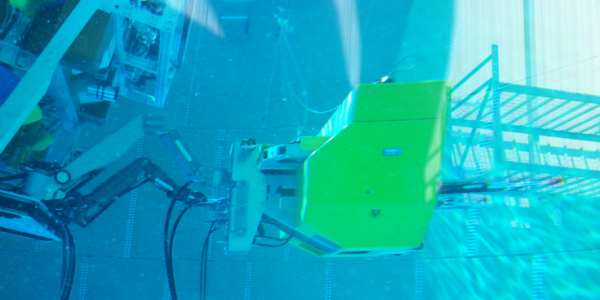

Creative solutions often come from creative equipment, and the ROV Diamond Wire Saw offers operators and contractors the ability to keep divers out of the water, maintain controllable and precise cuts, and operate at a subsea weight of approximately 160lb.

Mactech Offshore has both surface-controlled and ROV Diamond Wire Saws available. When considering ROV-operable, there are several considerations and levels of involvement that need to be evaluated to determine the scenario for subsea operation.

Here are some example scenarios for ROV application:

Scenario 1

Saw is deployed on a winch or crane line and operated by surface power. An ROV is used to position the saw at the cut location. Requirements: ROV handles may be required for the manipulator to grab.

Scenario 2

Saw is deployed on a winch or crane line, but is positioned and powered by the ROV. The acting saw and ROV are mated on the surface by hard plumbing hydraulic hoses. Requirements: ROV handles may be required for the manipulator to grab.

Scenario 3

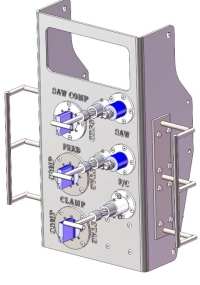

Saw is deployed on a winch or crane line, but is positioned and powered by the ROV. Mating is to be completed diver-less and subsea. Requirements: in addition to the handles, an interface panel with hot stab connections would be required. If the stabs are to be installed below 600FSW, a compensator would need to be added to the interface panel to equalize internal and external pressures. Mactech offers a compensated interface panel designed to withstand 10,000FSW. The interface panels can be custom-designed to fit to a specific ROV model and hot stab requirement.

Scenario 4

The ROV needs to freely "fly" the saw around while disconnected from the winch line. Requirements: a buoyancy package is added to the saw to reduce its wet weight to something manageable for the ROV. Wet weight of the saw without the buoyancy package is approximately 800lb, but lowers to 160lb with the package. A buoyancy package from Mactech Offshore is designed to withstand pressures to 10,000FSW.

If you would like more information about this solution, contact Mactech Offshore today.

Mactech Offshore’s versatility in the subsea and underwater machining world is what makes its capabilities truly unique. No job is too big or small, with cutting capabilities of machines ranging from four inches to 102in, and an expanding fleet of 36 diamond wire machines that have successfully performed more than 500 diamond wire cuts.

Mactech Offshore designs, develops and manufactures products used in the maintenance, repair, upkeep and decommissioning activities of the offshore oil and gas industry. Its products are specifically designed for operation in a subsea and potentially hazardous environment.