Mactech Offshore specialises in the offshore subsea market, deploying operators and equipment worldwide.

From split frame cutters to diamond wire saws, we have positioned ourselves to design, develop and apply these tailored cutting tools to marine services in the oil and gas industry and the offshore subsea market.

We have the equipment and experience to perform any rig maintenance and removal operation.

Diamond wire machines and systems

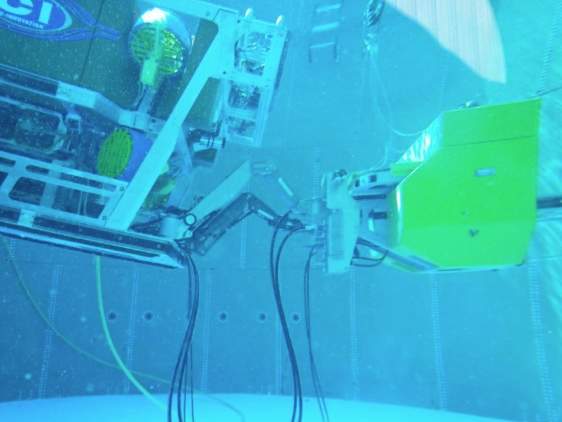

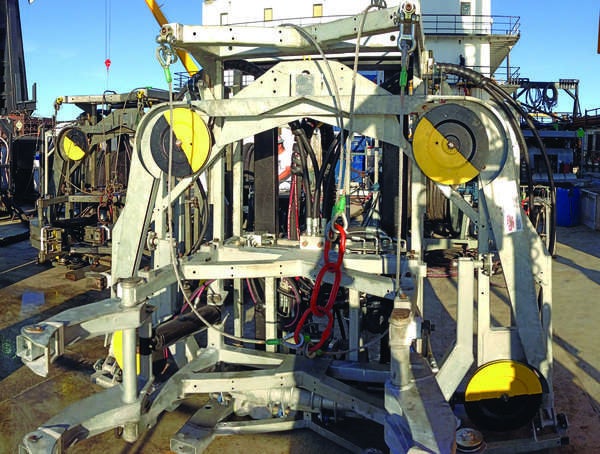

Mactech Offshore’s articulating diamond wire saws are designed to perform below-the-mudline or low-clearance cuts. The cutting capabilities of our machines range from 4in to 102in and are compatible with remote-operated vehicles (ROVs), which enable underwater cutting and maintenance.

An ROV is often unnecessary at times as the saw’s guiding arms can be closed around a pipe and act as an indicator as to where to make the cut.

Additionally, we have recently received patent-approval status for an articulating wire saw system that is designed for subsea and topside cutting.

Mactech Offshore currently has a fleet of 36 diamond wire machines, which have performed more than 500 successful cutting operations worldwide. We also have a variety of equipment available, including clamshell lathes, internal cutters and other cutting machines.

Cost-effective diamond wire solutions for underwater cutting applications

Articulating diamond wire saws are becoming a key tool in increasing the efficiency and effectiveness of low-clearance cuts in the subsea cutting world.

Mactech Offshore’s saws are ideal for cutting multi-string applications or heavy wall legs and cross members in the decommissioning industry, as they use diamond wire technology as a new way to make vertical cuts.

This orientation allows the saw to easily fit into narrow cofferdams or excavations, where other saws cannot fit or operate. The articulated design only requires 2ft of clearance around casings and the cut is made at the bottom of the saw, so there is no need to make additional space.

The compact and robust design creates an ideal cutting environment, as it reduces setup, installation and removal times, while saving time and money.

Split frame cutters

Mactech Offshore’s split frame cutters have recently increased their machining capabilities with attachments to perform milling, sawing and drilling operations.

These plug-and-play attachments provide an environment where unexpected situations become controllable and practical scenarios.

Internal cutting equipment has led to the increased success of machining cuts where the environment is not ideal for an external cut or where time can be saved from unnecessary external drilling or dredging around the mudline.

About Mactech Offshore

Based in Lafayette, Louisiana, US, Mactech Offshore uses the 28 years of field service and customised tool design of its parent company, Mactech, to bring innovative and productive underwater cutting solutions to the offshore market.