ProAnalysis is a supplier of oil-in-water (OiW) monitoring solutions, both for environmental monitoring and produced water treatment process monitoring.

The unique Argus® technology introduces a new generation of oil-in-water analysers that provide accurate and reliable measurements, and are used for water discharge monitoring, as well as produced water treatment process monitoring and management.

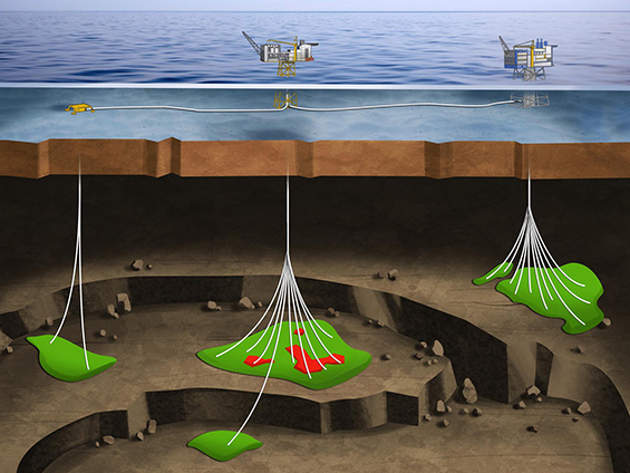

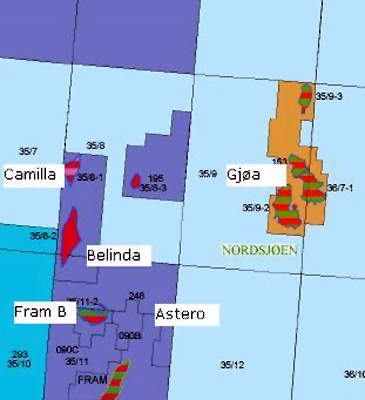

ProAnalysis’ unique proprietary Argus technology has been developed in close cooperation with major oil and gas operators in the North Sea, as a response to the need for reliable OiW monitoring technology operating in challenging process conditions.

Oil-in-water analysers for emissions monitoring and water treatment

ProAnalysis has developed two products from the Argus technology base:

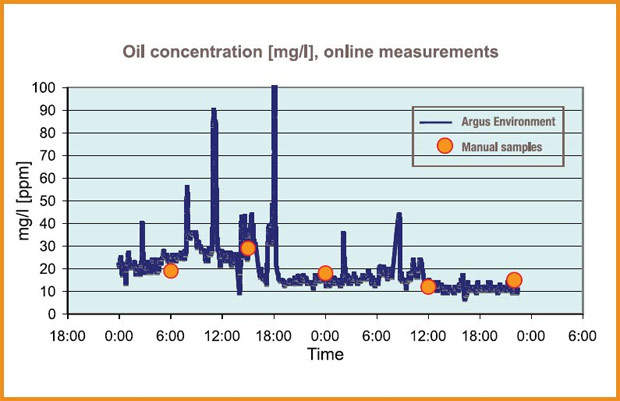

- Argus Environment for emissions monitoring, providing operators with oil-in-water concentrations continuously and real-time, and reducing or eliminating the need for manual sampling and laboratory analysis

- Argus Process for advanced produced water treatment process monitoring, including single or multiple measuring points at different stages of the process

Real-time oil-in-water analysis capability

A key component of the Argus system is the online inline oil-in-water analyser, which provides a continuous stream of real-time oil-in-water data.

Argus has been thoroughly tested at several North Sea oil and gas fields, and first commercial deliveries were made in 2005 and 2006.

Water treatment process measurements

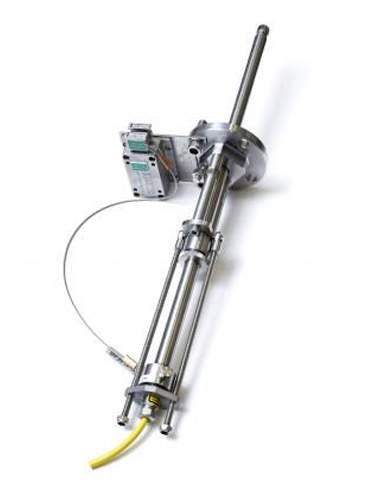

A main challenge associated with traditional OiW monitors is the need for bypass loops, which often are complex, expensive and require frequent maintenance. The Argus technology eliminates these problems as measurements are done through a permanent inline probe installed directly in the pipeline. The solution offers several significant advantages, including:

- Low installation costs, eliminating the need for expensive bypass systems

- Eliminates high-maintenance costs resulting from bypass lines being blocked by deposits

- Representative measurements under real process conditions; sampling through bypass systems is problematic under varying process conditions

- No moving parts – a non-mechanical system

- No consumables – a non-chemical system

- Integrated control software (Argus Manager), incorporating data logging and reporting modules, facilitating easy reporting of historic data

With its inline probe, the unique Argus technology design facilitates measurements at higher pressures and temperatures, enabling measurements throughout the water treatment process. Argus OiW monitors can be used for downstream separators, hydrocyclones, degassers and other process equipment, monitoring different stages of the process and providing the operator with unique process performance control.

Oil-in-water monitoring with laser-induced fluorescence

The Argus technology is based on the measurement principle (laser-induced) fluorescence. A laser, uniquely developed for the sensor, emits ultraviolet light directly into the process line by fibre optics. The laser light interacts with crude oil, and fluorescence is emitted, collected, transmitted by fibre optics, spectrally and temporally filtered and finally quantified by a light sensor. The technology offers several significant advantages:

- Established and proven measurement principle

- Stable and robust under harsh and changing process conditions (temperature, pressure, solids, gas, etc.)

- Accurate quantification of dispersed oil through the measurement of aromatic hydrocarbons (PAHs) – even at ppb levels

Self-cleaning oil-in-water monitors

To handle challenges related to contamination, Argus is equipped with an ultrasound-based technology for the automated self-cleaning of the inline probe. Cleaning of the optical process interface is mediated through an advanced, high-power excitation of the probe’s sapphire window.

The proprietary ultrasound-based self-cleaning technology has proven highly efficient at installations facing severe challenges from scaling on process equipment, making Argus practically a maintenance-free OiW monitor in any application.

High-pressure oil-in-water monitors

Argus Process monitors oil-in-water concentrations at high pressure and/or temperature locations in the water treatment process, paving the way for new applications for online OiW monitors.

Low-pressure oil-in-water monitors

Argus Environment monitors oil-in-water concentrations at water discharges to the environment, online and real time. Oil and gas operators are able to comply with HS&E regulations and reduce OiW levels without the need for manual water sampling and laboratory analysis.

Multipoint oil-in-water monitoring systems

The design of Argus Multipoint enables several in-line measurement probes to be connected to the same central control unit in a multipoint oil-in-water monitoring system, resulting in significant cost reductions compared to using separate OiW monitors at each measurement point.

Up to four inline measurement probes can be connected to the ATEX-certified field enclosure, which houses the Argus control unit (laser, optics and electronics). A typical setup includes one measurement point at the inlet to the produced water treatment system, one measurement point at the outlet, and if needed, one or two measurement points at different stages of the process. Such a system provides unique control and information about the efficiency of the produced water system.