Miko Marine AS of Norway has won a significant contract to supply Japanese-owned rig and platform builder MODEC with four cofferdams and water inlet covers for the latest floating production storage and offloading (FPSO) vessel that it is building for Equinor.

Construction of the new FPSO’s hull is being carried out at the DSIC yard in Dalian, China, and on completion, the vessel will be operated by Equinor on the Bacalhau field offshore Brazil.

The new sea chest inlet covers are scheduled for delivery in March 2021 when they will form part of the new FPSO’s equipment inventory making them available for use whenever required. They feature Miko’s magnetic attachment techniques and will be available to be fitted and used repeatedly without the need for welding or permanent hull attachments. They provide the benefit of enabling repairs and maintenance to be carried-out inside sea-chests whenever necessary and without the need for dry-docking, thereby enabling the FPSO to remain on station.

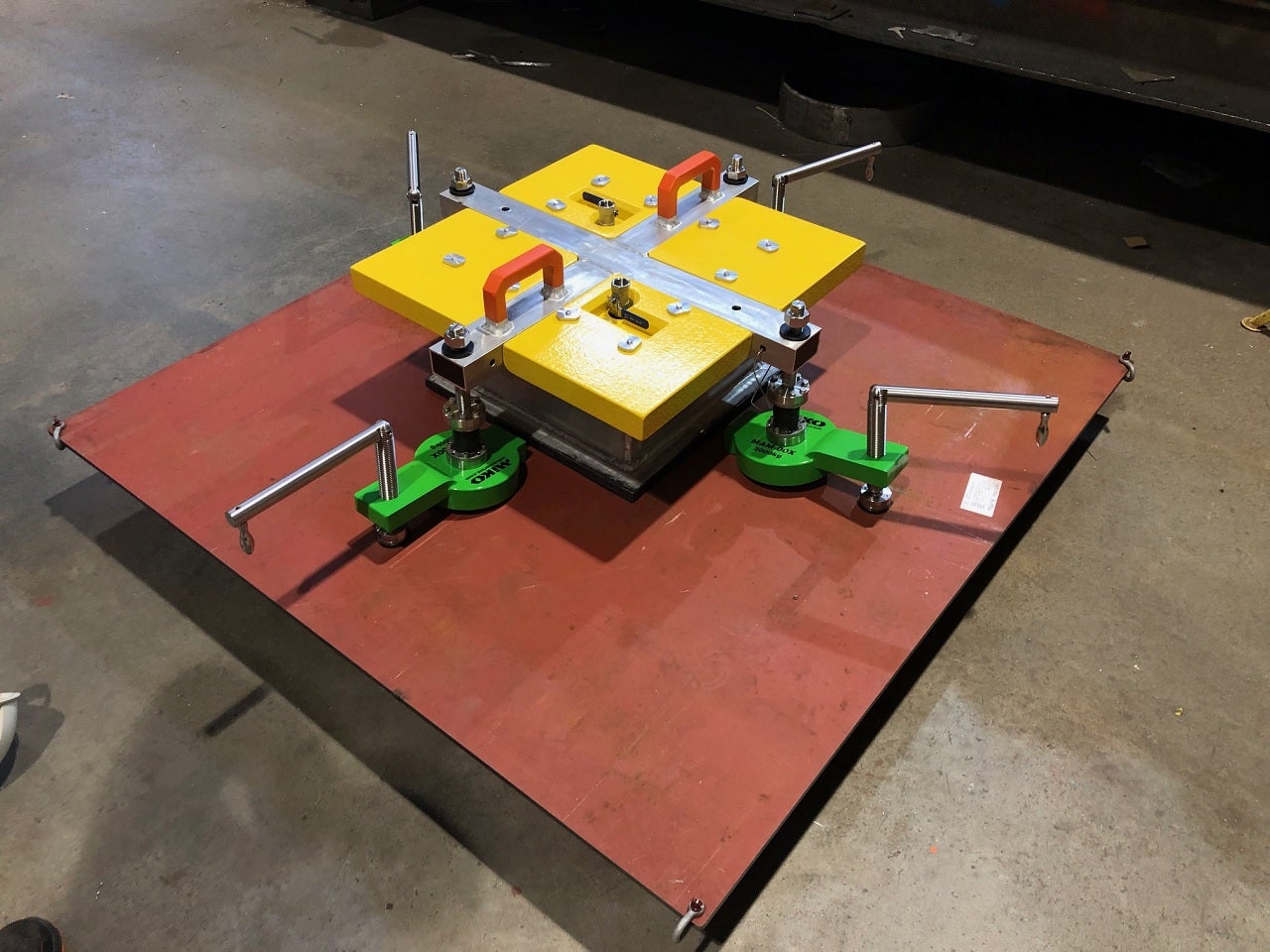

Miko has developed considerable expertise in the design and manufacture of hull closures and cofferdams. Their designs will vary according to the requirements of the individual vessel but the Bacalhau project will feature Miko’s successful and unique use of high-power permanent magnets to position and hold the closure in place. Depending on the size of the closure, four to ten powerful Miko MAM permanent magnets are used to hold the cofferdam in place.

With each magnet being capable of holding up to 2,000kg, it is possible to achieve an immediate watertight seal for the closures without the need for any other fastening devices being fitted to the hull. Flotation material is integrated within the blanking plates and this makes them neutrally buoyant and easily handled underwater by ROV. Each magnet is attached to its closure by a flexible joint which enables the plate to be manoeuvred and positioned precisely against the hull before it is tightened into place. When the repair work is finished the magnets are simply freed by having their release lever rotated by a diver or ROV, enabling the blank to be quickly retrieved by crane and stored onboard.

Miko Marine AS is based in Oslo, Norway, from where it also provides a range of unique salvage and support products for the marine industry. Most widely known is its range of magnetic plasters which can be used to seal hull damage and enable a vessel to be moved safely to a yard for permanent repair. The company’s most recent innovation has been the Moskito oil recovery tool that was recently introduced as the first device that can enable bunker fuels and other hydrocarbon cargoes to be quickly and easily extracted from the tanks of sunken vessels.