Miko Marine is dedicated to the application of magnetic science for solving problems in the offshore industry.

The company is a design specialist that applies its expertise in the practical use of magnets to a variety of challenges in the offshore oil and gas industry. It has unrivalled experience in finding better solutions to problems and has the know-how to employ magnets and magnetic technology wherever appropriate.

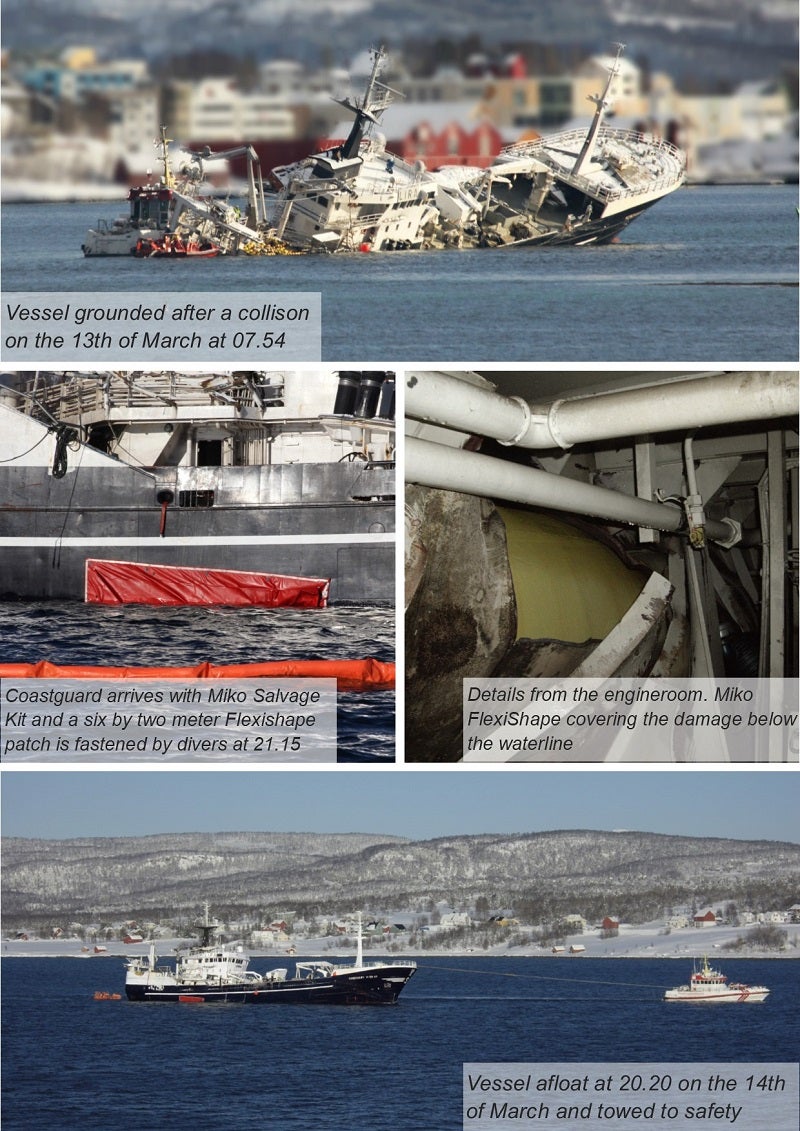

Patches for closing leaks and damage

Miko’s magnetic plasters are at the heart of the company’s product and service repertoire. Magnetic patches can perform the reassuring role of a sticking plaster when applied to a punctured hull or platform jacket.

Qualified by DNV and used throughout the world, Miko magnetic patches can create a water-tight seal in circumstances that might otherwise result in the loss of the vessel.

The Miko Marine service also ensures a quick response to emergencies such as collisions and groundings. It provides the right equipment and expertise for temporary, but dependable, hull or structural repairs.

Miko’s Kevlar reinforced Flexishape patches are used where uneven damage prevents the use of magnetic plasters. The strength of Aramid fibres is used in layers to create flexible patches that can cover curved surfaces or sharp and deformed plating. Rubber edging creates a watertight seal when the patch is applied tightly to the plating with Miko’s own underwater fastening system.

Magnetic patches and Flexi-shape patches can be supplied in kits customised for emergencies or planned in-water repair. The kits contain a choice of patch types and sizes and all necessary tools for a safe operation.

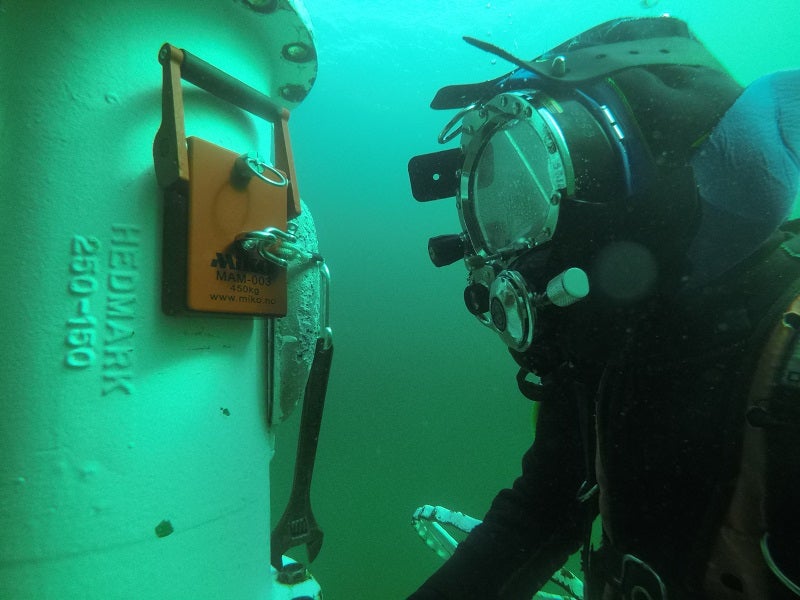

Magnets for fastening and anchor points

With a holding force ranging from 90kg to 2,000kg, Miko magnets fulfil a variety of functions below or above water offshore. With over 17,000 sold worldwide, Miko magnets perform tasks ranging -from fastening items such as diving equipment, anchor points and guide wires for divers to securing instrumentation, including acoustic transponders to subsea structures.

The stronger magnets are used for fastening large objects such as oil booms or other types of heavy diving equipment. They can also be used to create temporary mooring points for lighter vessels, for example, a survey boat, barge or similar, to the ship side or to the rig leg.

The neodymium magnetic components of the magnets are coated with epoxy to improve their corrosion resistance in seawater. They are equipped with a mooring lug and breaking lever for easy release and safe operation. Each magnet also contains a rubber filling which creates increased friction and improved usability.

ROV magnet

With a holding force of 750kg, the Miko ROV-magnet is designed specifically for ROV-use. It is compatible with all common types of manipulator claws and has a mechanical on/off function that enables the gentle handling of painted subsea installations, fragile wrecks and other underwater steel structures.

An interchangeable fixing bracket allows the most appropriate design to be chosen for the job. Connectivity with more ROV-magnets can increase the holding force and make it ideal for stabilising a work-class ROV during a range of tasks. These might include retaining ROVs during inspections or welding operations, performing underwater heavy lifting operations, the temporary storage of ROV tools and for the creation of fixing-points for lights or cameras

Combined with a high-quality pressure compensator, the stainless-steel (SS 316L) housing ensures that Miko’s ROV magnets are corrosion-resistant and usable at all depths.

Pipe closure plugs for maintenance and repairs

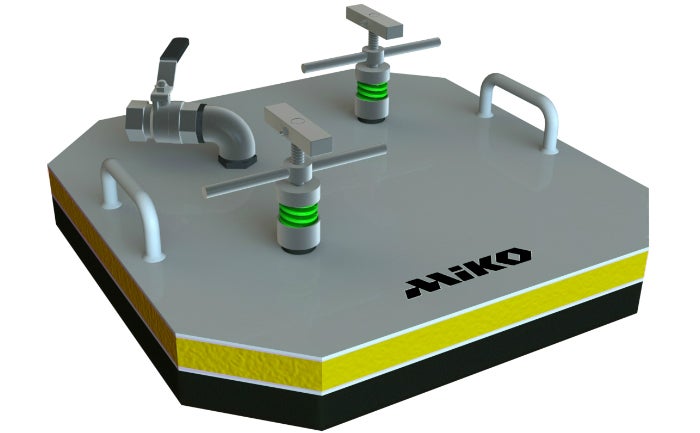

Miko offers highly effective standard and customised plugs for sealing pipes during maintenance or repair work. When inserted into the pipe to be sealed, a watertight barrier is established simply by closing the turning bar. This squeezes the aluminium disks together and expands the soft rubber rings between them. The crossbar prevents the plug from being sucked into the pipe and the through-bore and valve enable the pipe to be flooded before the plug is removed.

Miko plugs have proved highly effective and simple to use for planned maintenance, in-water survey or repair emergencies and during marine salvage operations.

Miko emergency pipe repair kit

A kit developed by Miko can seal leaks in high-pressure pipes by using specially formulated rubber patches. These are slid over a leak and held in place by ratchet straps. The kits can be used to seal leaks in pipes ranging from 2-inches to 20-inches in diameter and can cover holes up to 1-inch across. Tests by Miko designers have demonstrated that when using the correct application technique users can successfully seal a leak through which liquid is escaping at pressures up to ten bar.

Tank Sealer Kit

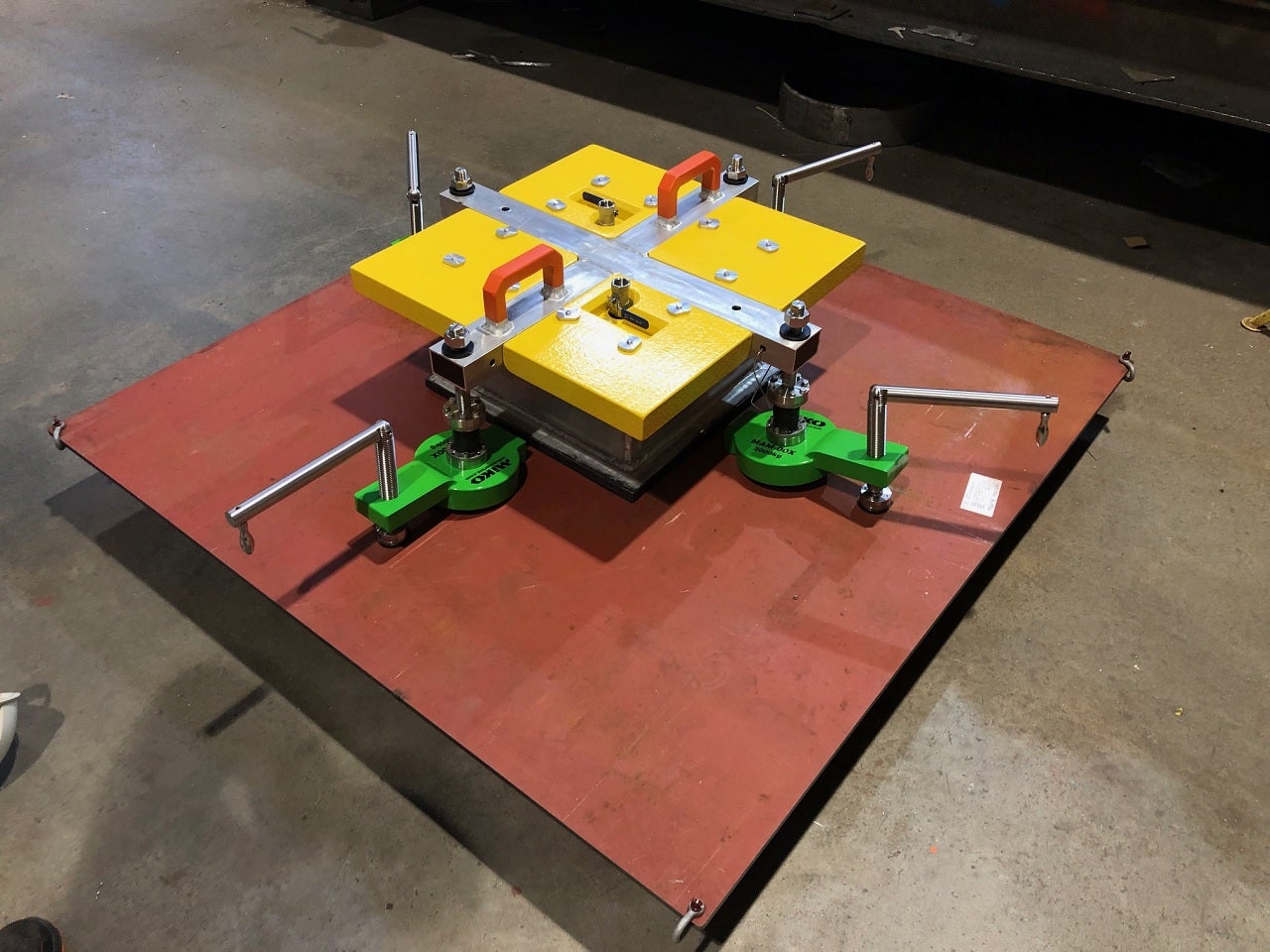

Used for sealing leaks in oil storage tanks, the kit contains two powerful magnetic patches of different sizes. The most suitable one can be applied to cover a leak whether it is above or below water. It can be further secured with powerful permanent magnets supplied with the kit.

The patch easily resists the pressure of the escaping liquid while a layer of soft neoprene at its centre enables it to fit the shape of the hole and maintain a leak-proof seal until the tank can be emptied and a permanent repair made.

The kit contains two Miko anchor magnets each with a holding force of 450kg and four smaller magnets capable of holding 90kg each. Despite being exceptionally strong permanent magnets, they are all equipped with a release lever that enables them to be detached and repositioned with ease.

When used in conjunction with the magnetic layer of the Plaster they provide extremely powerful adhesion that is capable of retaining any volume of hydrocarbons until the tank is emptied for repair.

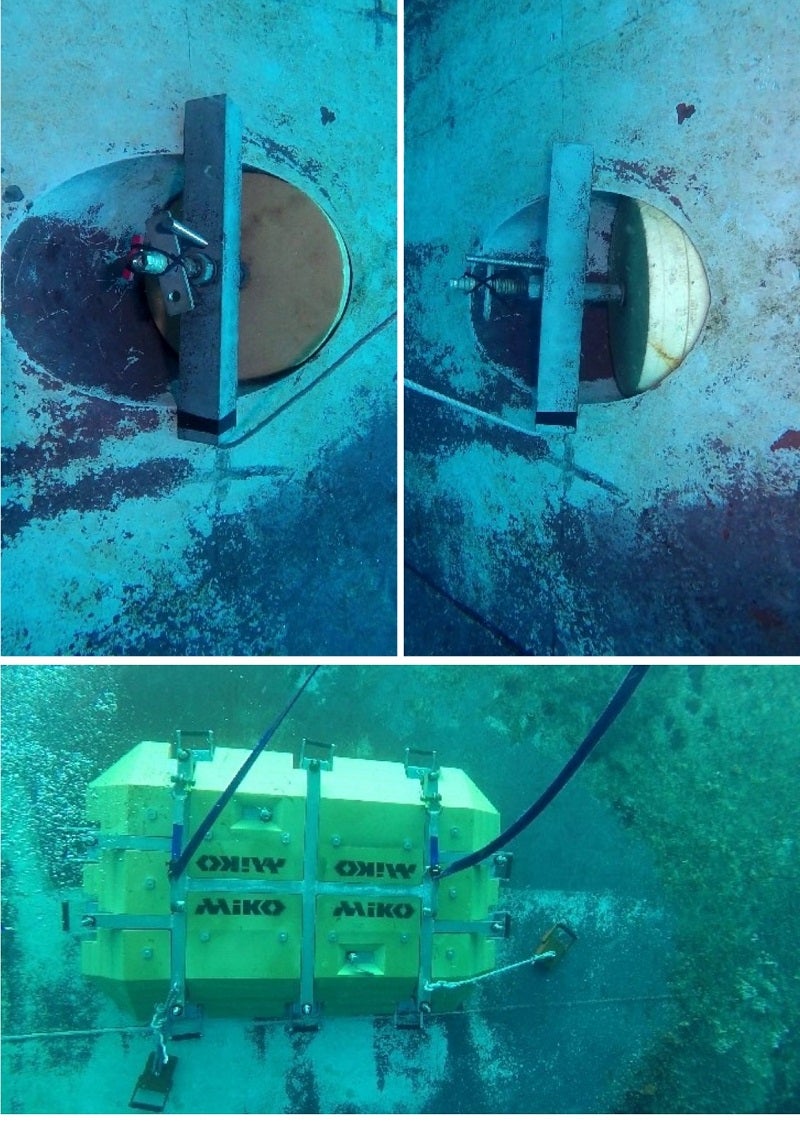

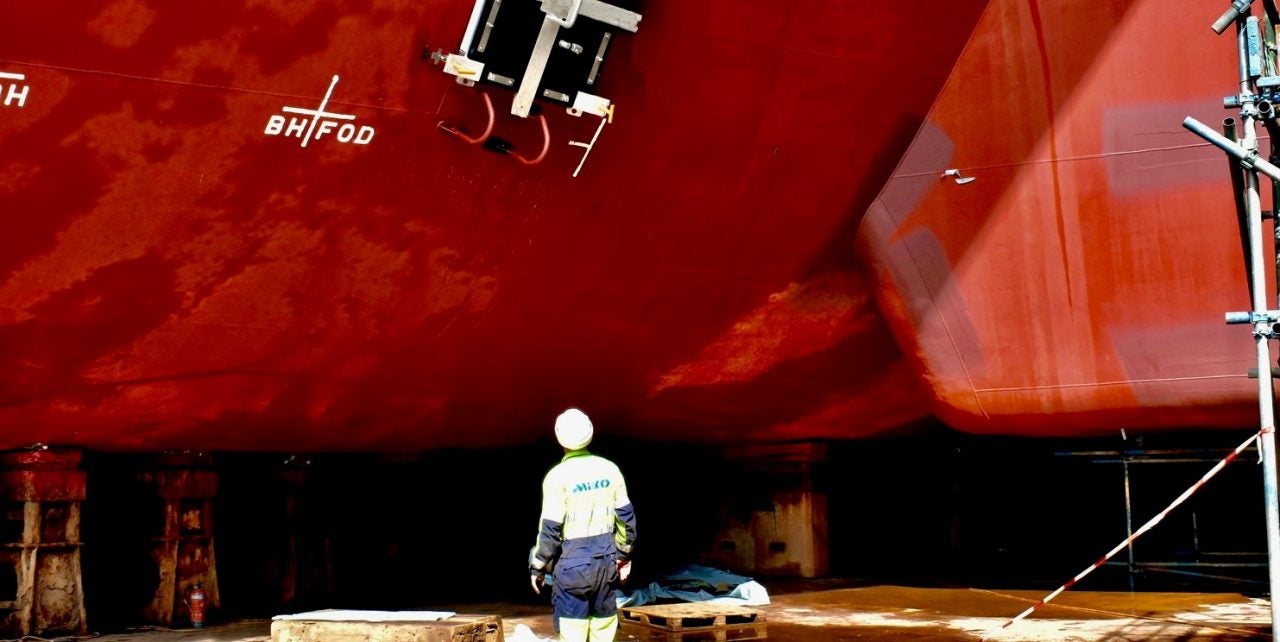

Hull and sea chest closures

Miko hull closures and cofferdams combine custom manufacture with magnetic adhesion to provide a fast and efficient method of closing hull openings during repair and maintenance work.

The closures are manufactured by Miko to fit the curvature of the hull and are held in position by powerful permanent magnets or mechanical spring-loaded latches.

Used on major oil industry repair contracts they are shown to provide valuable time and cost savings when compared with traditional sea chest closure methods. 3D laser scanning enables precision manufacture of the Miko blanks and ensures a perfect fit against the curved hull profile.

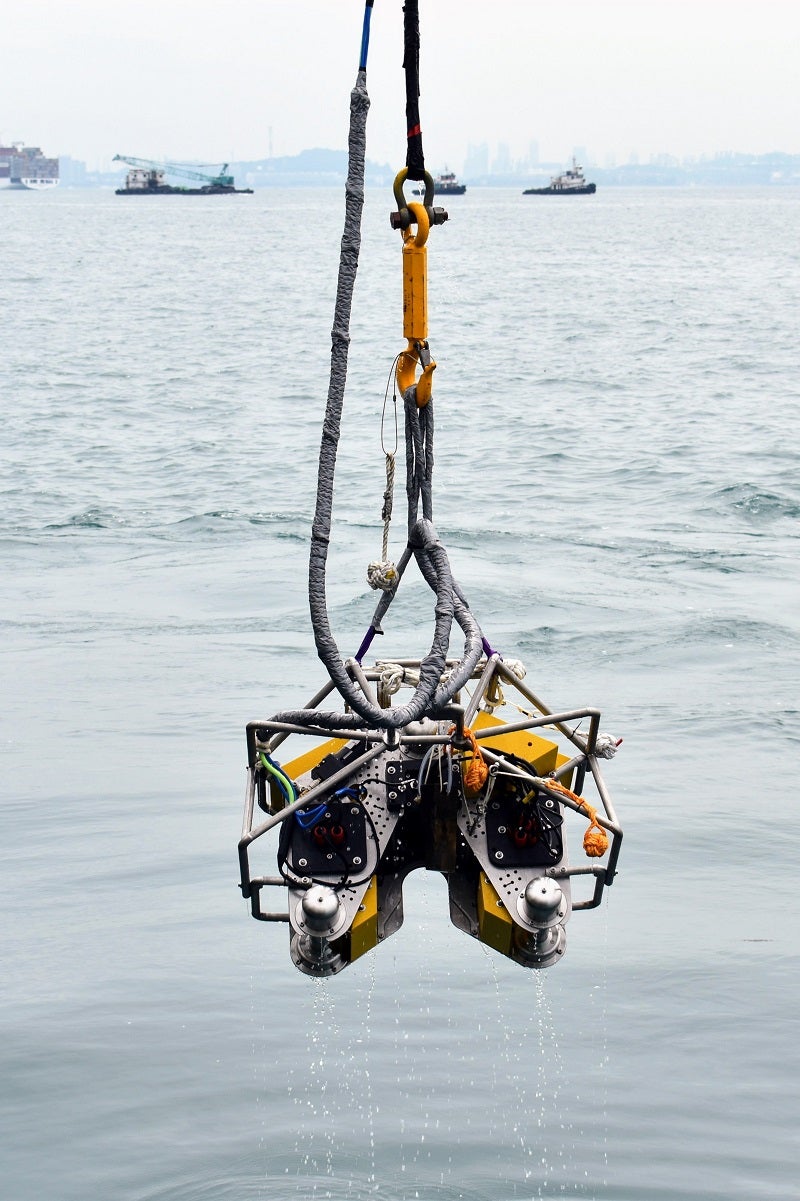

Powerful Miko MAM permanent magnets, each capable of holding up to 450kg, create an immediate watertight seal for the closures without the need for any other fastenings being welded to the hull. The neutrally buoyant plates are easily handled underwater by ROV and on completion, each magnet is simply freed by having its release lever lifted by a diver or ROV so the blank can be quickly retrieved by crane.

Miko Marine AS

Miko Marine AS was founded in 1996 to develop and market its unique magnetic patches. The company is based in Oslo, Norway, from where it also provides a range of unique salvage and support products for the marine industry.

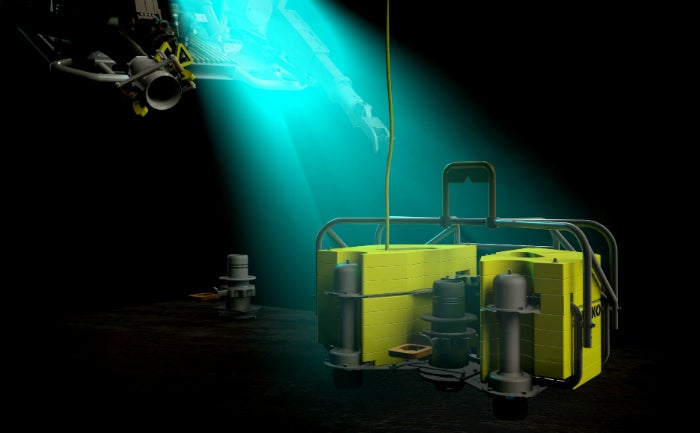

The company’s most recent innovation has been the Moskito hot-tap oil recovery system. This was the first tool that can enable bunker fuels and other hydrocarbon cargoes to be quickly and easily extracted from the tanks of sunken vessels. The Moskito was recently used to recover 400t of heavy fuel oil from the tanks of the sunken general cargo vessel Thorco Cloud.