/scenery-1.jpg)

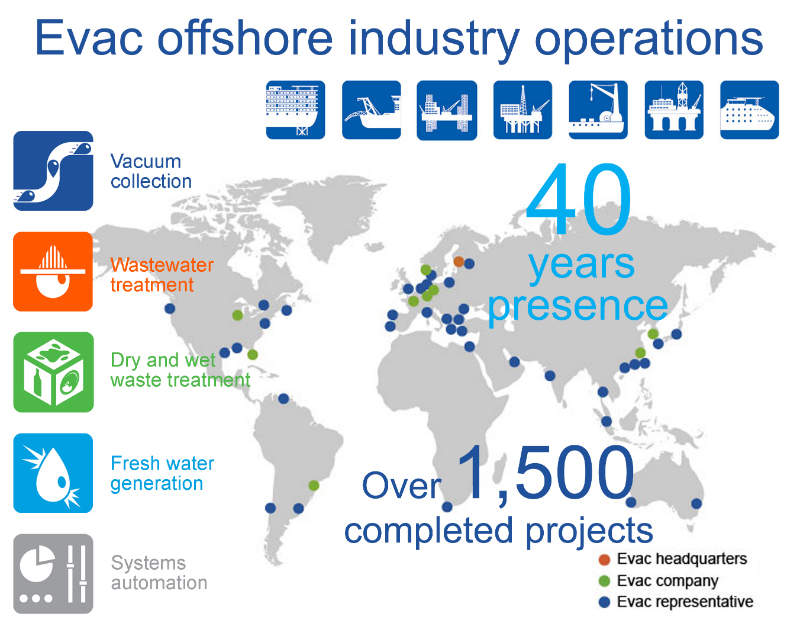

Evac is a global leader in the provision of wastewater, water management and integrated waste solutions for offshore and building applications.

We have successfully conducted more than 20,000 marine, 2,000 offshore and 2,000 building projects for clients worldwide, and have employees in Europe, Asia and the US, in addition to representatives in more than 40 countries.

Sustainable water solutions for marine applications

Evac considers sustainability to be the cornerstone of all its activities and the company is committed to developing technologies that address the increasing demand for innovative Cleantech solutions, which has been driven in recent years by climate change, the need for energy efficiency, and the growing global scarcity of fresh water resources.

Our vision is to promote clean and sustainable operations worldwide by helping our customers meet their waste and water management performance targets across a wide range of industrial applications.

We aim to contribute to a greener environment and cleaner seas by ensuring our clients are able to:

- Reduce industrial water consumption

- Purify wastewater

- Treat and recycle their waste responsibly

- Generate fresh water from seawater.

- Manage food waste responsibly and sustainably

Leading expertise and product development for oil and gas projects

Evac’s dedicated in-house product development team are continuously developing new products and refining existing systems, and our experienced technology specialists are able to support and advise customers’ engineering personnel in order to help identify the most suitable and effective solution for their individual project requirements.

Our customers benefit from the combined advantages of a global supply chain and with local flexibility, and we are able to provide expert solutions, cost-efficient procurement and rapid delivery of spare parts and components wherever clients’ vessels or platforms are located.

Environmentally compliant marine waste solutions

Evac regularly works in close collaboration with the relevant authorities and standards bodies during offshore projects in order to ensure our systems meet the strictest local and global environmental requirements.

Our operations are fully compliant with the latest ISO 14001:2004 (Environmental Management Systems), ISO 9001:2008 (Quality Management Systems) and OHSAS 18001:2007 (Occupational Health and Safety Management Systems) regulations.

Comprehensive Cleantech solutions for offshore projects

Sourcing the complete range of waste, wastewater and water management solutions needed for a project from a single supplier improves coordination and integration, and increases the efficiency of management and maintenance once installation is complete.

Our Complete Cleantech Solution is a comprehensive system that covers all waste and water requirements, including wastewater treatment and vacuum collection, in addition to fresh water generation and dry, wet, and food waste management.

Vacuum collection systems for industrial sewage treatment

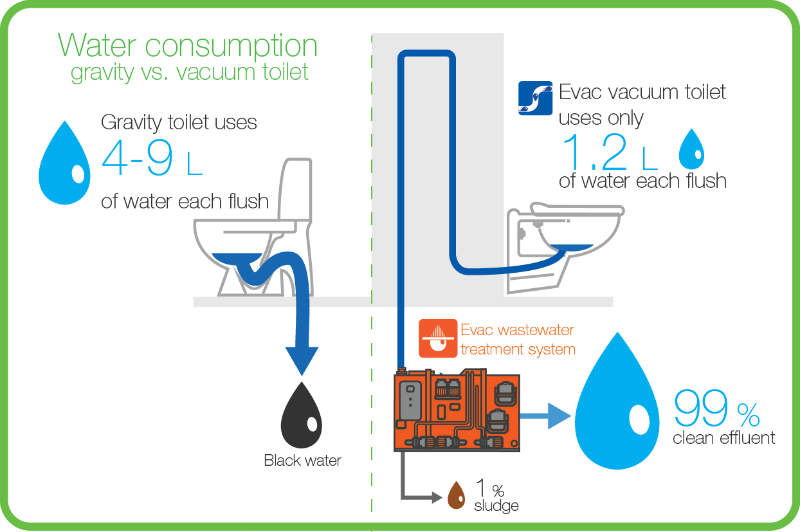

Vacuum collection devices efficiently collect food waste, sewage and condensation and transfer it to a collection tank or treatment plant using vacuum pump technology.

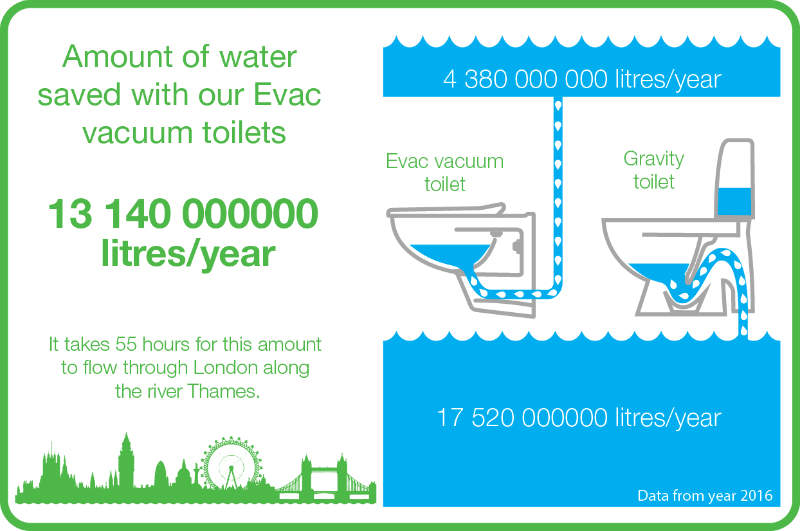

Evac has been designing, manufacturing and supplying a variety of powerful vacuum collection solutions to customers for more than four decades, including a number of food waste collection units, water-saving vacuum toilets, and vacuum and collection units for condensation, which are often deployed in conjunction with cooling systems both on land and at sea.

Electrolytic wastewater treatment systems for oil and gas platforms

Wastewater treatment solutions efficiently separate and neutralise various organic contaminants present in wastewater in order to comply with national and international health and safety regulations.

Evac is able to provide an extensive line of wastewater treatment systems such as biological and electrolytic wastewater treatment units that have been specially designed to refine black and grey water, as well as grease separating solutions for galley and kitchen wastewater applications.

We also offer a range of advanced moving bed biofilm reactors (MBBRs) and membrane bioreactors (MBRs), which are cutting-edge biological sewage treatment solutions optimized for industrial environments. MBBR devices are primarily suitable for large cruise vessels, while our versatile MBR systems can be used on a wide range of vessels. Both solutions feature nutrient removal capabilities.

Our electrolytic wastewater plants are the ideal solution for offshore oil and gas platforms / vessels, as well as a variety of naval applications.

Dry and wet waste treatment for offshore sites

Evac’s energy-efficient dry and wet waste treatment systems are able to manage mixed or recyclable waste matter in a safe and environmentally friendly manner, while reducing volume through a mix of shredding, burning and compaction processes.

Our product range includes a variety of cost-effective and low-maintenance dryers, incinerators, waste briquetting systems, bio sludge treatment units, as well as other compaction and food waste treatment solutions.

Freshwater generation for marine applications

Evac’s freshwater generation equipment filters and disinfects regular seawater, turning it into clean water for service, process and drinking applications. The systems can also adjust the water’s hardness and mineralise fresh water if required.

We provide a range of solutions that leverage reverse osmosis (RO) to desalinate seawater, in addition to a number of portable water treatment units for disinfection and mineralization purposes. Our product portfolio contains systems optimized for the varying requirements of merchant, passenger, naval and offshore environments.

Our RO desalination units are more economical and consume less energy than evaporation-based solutions, and are capable of achieving even higher energy-efficiency rates when used with energy recovery systems due to shortened amortisation times.

Automated systems for efficient water management

Evac’s integrated vacuum collection units, waste treatment solutions and fresh water generators are equipped with touchscreen panels for easy control, and all the company’s systems feature similar user interfaces to allow for hassle-free operation, supervision and maintenance across platforms.

Our primary automation solution features all systems on one single interface to facilitate fast and reliable remote programming, while having all real-time information accessible in one place allows for easy supervision and diagnostic processes.

All our modular and flexible systems can be installed and removed when required, and each solution makes use of the same spare parts and components, thereby reducing the costs and storage capacity required for maintenance.