Timken offers a complete line of solutions for the oil and gas industry, including alloy steel, bearings, maintenance tools, condition monitoring, engineered surfaces and more.

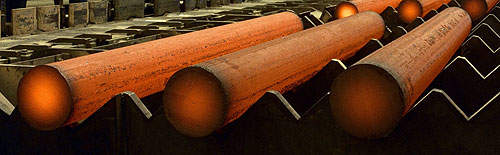

With more than 1.5 million tons of annual melt capacity, Timken produces one of the widest ranges of specialty steels in the world. Most of that steel leaves the Timken steel-making facilities in the form of alloy and carbon solid bars or billets. In addition, much steel is produced as seamless mechanical tubing that is used both in our own bearing plants and also by our customers.

Timken helps offshore drilling customers overcome the unique challenges of the industry, including harsh environments and costly equipment downtime. Offshore drilling companies depend on Timken for technology that helps keep their drilling and production strings running at top performance.

High-strength steel

Timken specializes in steel that has the strength and corrosion resistance needed for energy exploration and production. Through enhanced products, Timken helps offshore customers drill deeper. Timken produces ingot-cast and continuous-cast steel bars in three steel-making facilities. Rigorous quality control at every process step, combined with advanced inspection capabilities, ensure that Timken® steel products will be up to the task in even the most demanding customer applications, such as:

Steel for offshore drill bits

Deeper wells and harsh drilling environments put much higher demands on the toughness and longevity of drill bits. Timken steels have been instrumental in increasing bit life and have helped to set many drilling depth records.

Alloy steel for drill collars

Timken alloy steel bars, as-rolled or quench-and-tempered, are the preferred choice of drill collar manufacturers due to consistent chemistries and good surface quality.

Heavy-wall drill pipe steel

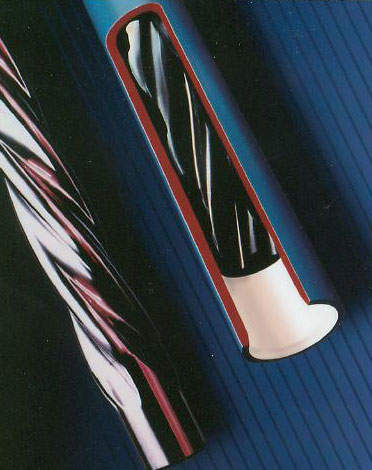

Strong but flexible, Timken seamless mechanical heavy-wall tubing is produced to provide the strength necessary for the transition zone between pipe and drill collars.

Steel for mud motors

Timken developed Impact® steels to meet the needs of mud motors. Seamless mechanical tubing produced from Impact steels is now the benchmark for demanding applications.

High-quality tool joint steel

Timken steel tubing and bars provide tight chemistry control and consistent response to heat treating.

Bearings for oil and gas drilling equipment

Timken is one of the largest suppliers of bearings to the critical equipment used in the oilfield industry. Equipment producers and drilling contractors look to the performance and reliability of Timken bearings in key equipment, such as top drives, mud pumps, crown and traveling blocks, draw works, and jacking systems. Timken offers a complete range of bearing types, from standard designs to bearings engineered specifically for the demands of oil and gas drilling equipment. Timken bearings help customers improve equipment performance, lengthen maintenance intervals and reduce bearing replacement costs.

Value-added boring services

Timken Boring Specialties, LLC (formerly part of Boring Specialties, Inc.) combines leading well boring and finishing products with a wide range of Timken high-quality alloy steel bars and tubes, resulting in a one-stop steel source for customers in the energy market segment.

Timken produces some of the cleanest, highest-quality steels in the world for the most demanding applications. The majority of steel manufactured by Timken is custom melt steel to the customer’s chemistry and manufacturing specifications. Timken also produces standard ASTM grades and quality level steel, which is a higher performing and longer lasting steel than offered by our competitors.

Where no steel exists that will do the job, The Timken Company keeps the world turning with innovative friction management and power transmission products and services that are critical to help hard-working machinery perform efficiently and reliably. With 2010 sales of $4.1bn and operations in 29 countries with approximately 20,000 people, Timken is Where You Turn® for better performance.