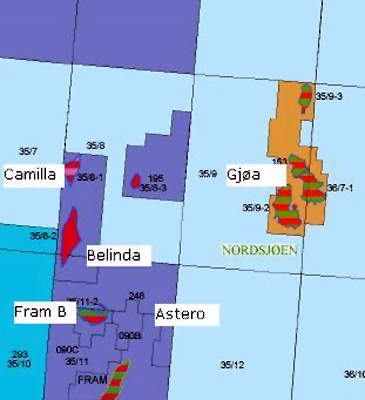

Scanmudring specialises in deepwater seabed intervention. Scanmudring delivers complex intervention operations for the excavation, removal or relocation of all types and quantities of seabed soil. We operate in deepwater, difficult conditions and in areas with restricted access worldwide.

Subsea intervention services

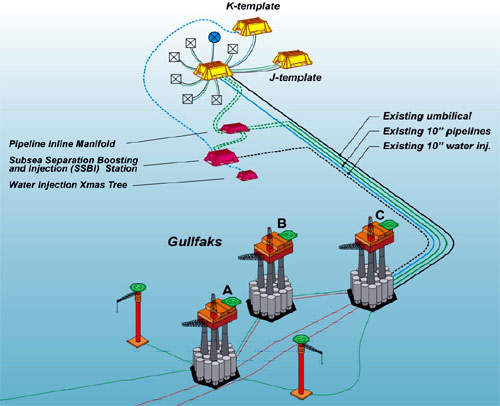

Scanmudring was established in 1985. Offices, workshops and test quay access are located in Mandal in the southern part of Norway. Scanmudring’s core business is within subsea intervention – primarily for the offshore oil, gas and energy industry – in connection with the installation, maintenance and modification of subsea equipment, as well as decommissioning and spudcan dredging. Scanmudring provides equipment and services for the removal of drill cuttings and rock dump, dredging and seabed levelling and pipeline deburial.

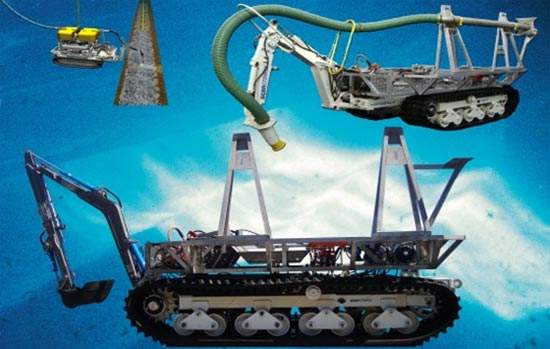

Scanmudring has designed, developed and operated its own specialised machinery: Scanmaskin, Scancrawler, Scandredge, Scangrabber, and ScanROVdredge manipulator. All Scanmudring’s equipment is designed for performing accurate and controlled operations in rough environments in 10m to 1,000m of water depth. In addition, our engineering capacity is engaged in studies, methods engineering and development of equipment.

By monitoring the projects for several thousand hours of subsea operation, we are proud to declare that our skilled operators and reliable equipment ensures that the projects are completed with a high focus on safe performance and efficiency.

Subsea excavators and tool carrier systems

The Scanmaskin subsea excavators and tool carrier systems are based on modified excavators combined with ROV technologies. This combination harnesses the experience of advanced subsea technologies and the ruggedness of land-based construction machines.

All Scanmaskin systems are uniquely designed for rapid mobilisation and for the performance of accurate and controlled operations in challenging environments such as strong currents and reduced visibility in water depths of up to 1,000m. All Scanmaskins are fully equipped with our in-house monitoring system (MoS).

Subsea WROV-powered excavator and tool-carrier system

The Scancrawler is developed and operated by Scanmudring. The system consists of the unit and control panels only. It is built on the foundation of a Scanmaskin, and is powered and controlled through wet docking a ROV to the unit. Operation is controlled and monitored with our MoS system from the operating position in the ROV control container. It can be operated from a vessel or a platform.

ROV and diver-operated dredge system

The Scandredge series seabed-positioned dredge ejector system is identical to the successful system used on the Scanmaskin, which is arranged on a certified lifting frame. The Scandredge can be supplied for both ROV and diver operations and has been used successfully in a range of underwater constructions worldwide. It is available in two different configurations: electric and hydraulic powered standalone dredge systems. The Scandredge for ROV operations is normally included with a Scandredge ROV manipulator.

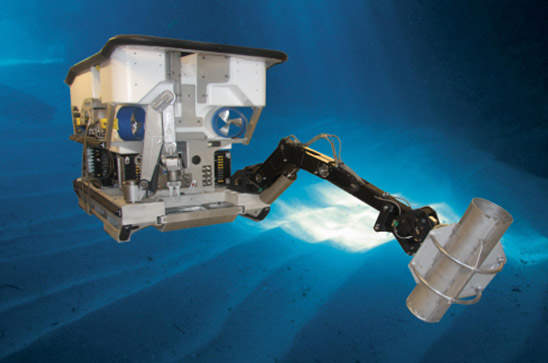

ROV dredging manipulator

The Scandredge ROV manipulator is a five function, rate-controlled manipulator, especially designed for ROV dredging operations, with nozzle size from 10in to 14in. This manipulator is designed to pick up and manoeuvre the dredge nozzle to optimum position; it is mounted in a front of a work-class ROV.

Permanent dredging tool for ROVs

ScanROVdredge is a specialised tool developed for minor work and cleaning tasks. The ScanROVdredge is optimised for weight vs. performance for use on lightweight and work-class ROVs, as a permanent fitted dredging tool. The ScanROVdredge is assembled, operated and maintained by the ROV team. The ScanROVdredge can be supplied with a water jet on the suction nozzle. The water jet function is manually activated by using the ROV manipulator.

For more information please contact the office in Mandal, Norway.