Maxwell Oil Tools offers composite innovations for the upstream petroleum industry, with a range of centralising systems.

Our centralising systems are engineered specifically to each client’s unique well design and are guaranteed to reduce friction factors and resist abrasive wear. These systems can be applied as casing or liner centralisers, drill pipe protectors or customised downhole solutions. Whether drilling a well or deploying a casing string, Maxwell’s composite tools aim to outperform conventional products available on the market.

Light and durable composite materials

The exceptional performance of composite materials makes them an ideal solution for centraliser systems in tight tolerance situations where friction is a major factor.

Maxwell has borrowed concepts from industries such as auto racing and aeronautics, which are trending towards lighter materials with higher mechanical strength. Maxwell has augmented these materials by adding a proprietary matrix of micronised particles with Kevlar reinforcement to optimise strength and longevity.

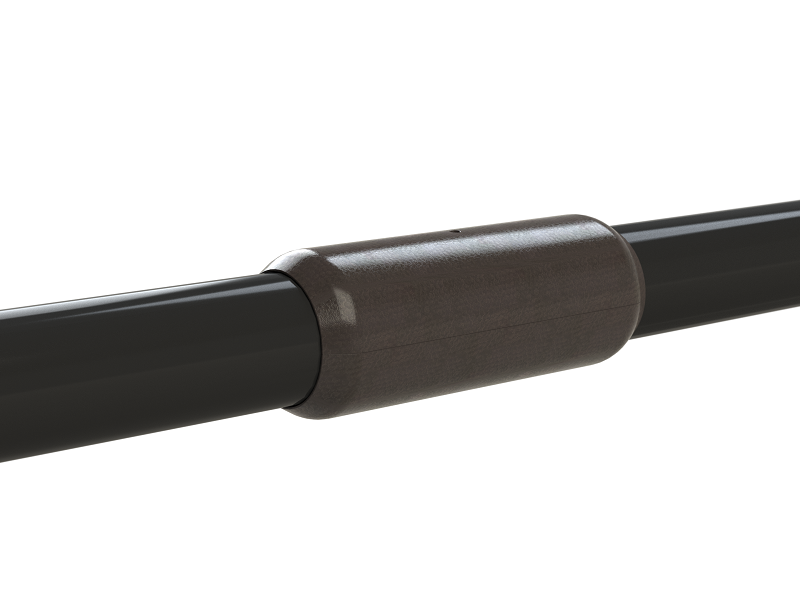

Protectors for drill pipes and casing

When applied as a drill pipe protector, under high side load and rotation, MAXDRILLTM composite materials drastically reduce casing wear and help prevent expensive tie-back work where the casing wall has been compromised.

The reduced friction in open hole allows operators to plan longer and more aggressive wells to optimise pay zone coverage. Emerging designs allow drilling teams to quickly replace the protector when it has reached its lifespan.

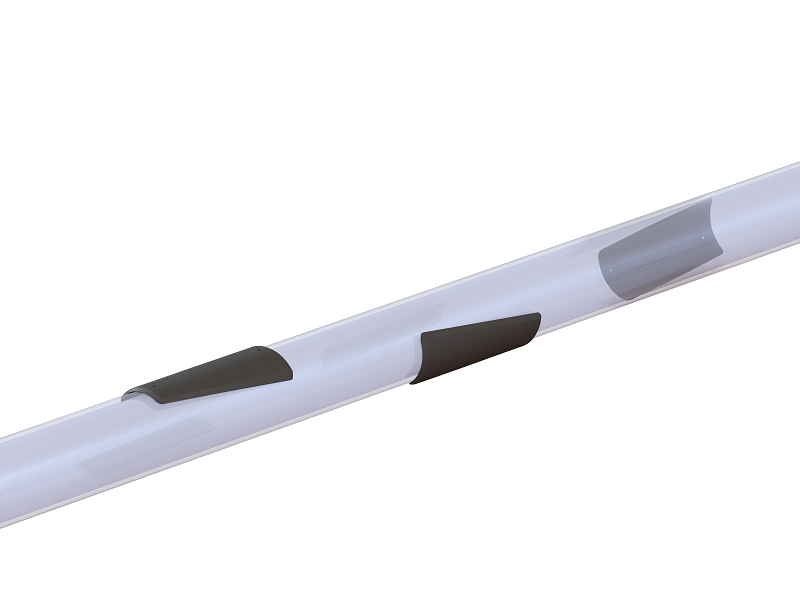

Ceramic and composite centraliser directly bonded to your tubular

The offset Multilayer Composite Centralizer (MCCTM) system significantly reduces friction factors during casing and liner placement. Conventional, one-piece centralisers restrict flow while pushing debris downhole, which increases the force required to reach measured depth.

By bonding the shell directly to the pipe, Maxwell has eliminated the need for bulky stop collars to optimize fluid flow and maximize debris dispersal. This results in reduced torque and drag, lower ECD values, mitigation of surge effect, and faster casing string deployment.

Low friction factor for extended reach drilling projects

Using Maxwell’s line of composite tools has resulted in record-breaking extended reach drilling projects worldwide. Producers are now able to run larger casing strings further downhole to increase production volumes.

By offsetting the centralisers down the length of the casing, Maxwell has optimised well bore standoff, creating more consistent cementing and increasing overall well integrity.

High quality offshore centralising systems

Maxwell makes quality control paramount to its corporate culture. Every shell is inspected before being shipped to ensure no defects are present. Field technicians constantly verify the integrity of the epoxy after installation and measure the profile of each shell before signing off. If any step of the installation fails the quality control process, the unit is reinstalled and verified before being released.

Worldwide presence and on-site installation

Our systems are now being used offshore in the North Sea, West Africa, and the Gulf of Mexico. Maxwell has won product qualifications with some of the largest oil and gas producers in the world and is becoming a benchmark for drilling and casing placement efficiency.

With offices in Italy, Scotland, Norway, the US, Middle East and Canada, Maxwell Oil Tools representatives are present in some of the most important energy-producing nations.