PaR Marine, a division of PaR Systems, includes the companies Jered LLC, Marine Systems Technology (MST) and PaR Marine Services.

PaR Marine’s companies have expertise with electro-mechanical, electro-hydraulic, and pneumatic equipment design, systems engineering, advanced automation, and heavy material handling technology, as well as other innovative technologies.

Cranes, hoists, elevators, anchor windlasses and boat launch and recovery systems

Jered LLC, the largest PaR Marine company, is an engineering, manufacturing and project management company that has served both commercial and government markets since it was founded in 1946.

PaR Systems Inc, the parent company in Shoreview, Minnesota, US, has provided remote handling and robotic systems for aerospace, industrial, life sciences, and nuclear applications for more than 45 years. Jered LLC has a long history supplying marine products such as cranes and hoists, elevators (aircraft, cargo, personnel), steering gear, boat launch and recovery systems, anchor windlasses, and other deck equipment.

Fireproof doors and bulkhead systems for offshore applications

With the acquisition of MST, PaR Marine now offers fireproof doors and bulkhead systems. MST developed COMFIRE®, a state-of-the-art composite based on recycled glass that is not only stable in fire, but also offers non-combustibility with no smoke or toxicity and excellent thermal and sound insulation properties.

With MST, PaR Marine now offers fireproof, gastight, watertight, and weathertight doors in both hinge and sliding configurations.

PaR Marine offers expertise to the offshore industry in the following areas:

- Overhead hoists / heavy lifts

- Elevators (cargo / personnel)

- Material handling systems

- Deck equipment (winches, lifting technologies)

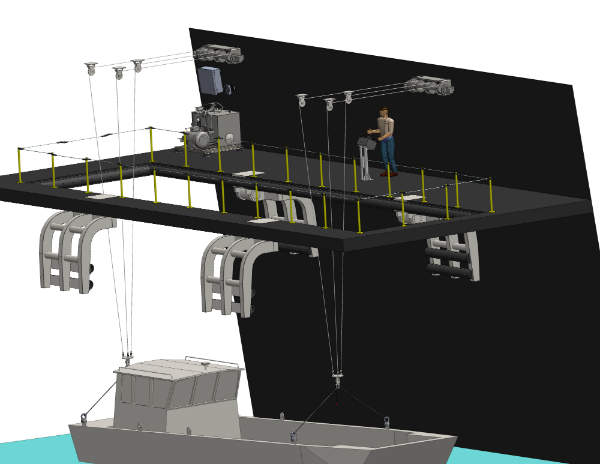

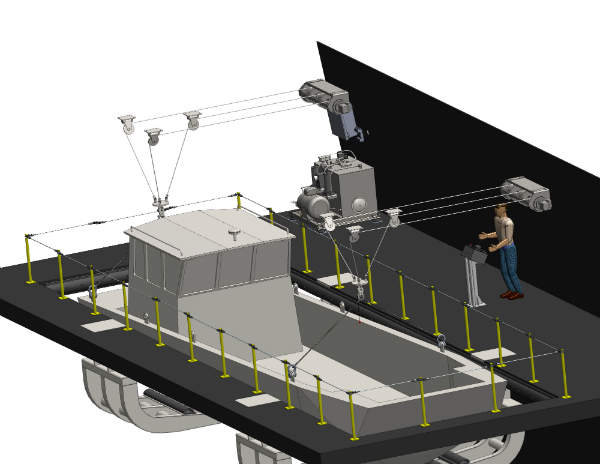

- Small boat launch and recovery systems

- Specialty engineering and fabrication

- Automation (surface and subsea)

- Fireproof doors and bulkhead systems

- Fireproof modular living quarters

Bridge crane designs and marine hoisting solutions

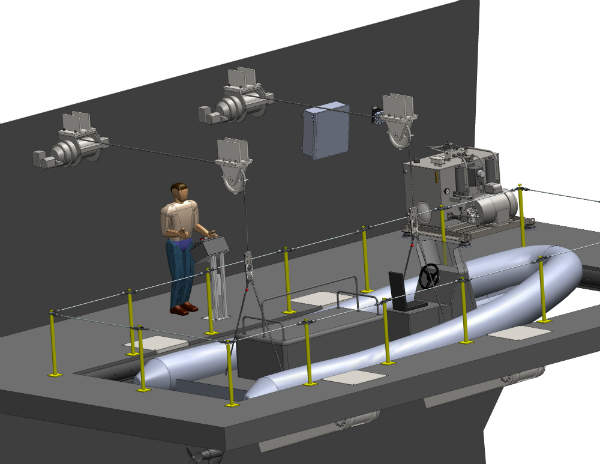

One of PaR Marine’s bridge crane designs is rated at 12,000lb at 45ft per minute (bridge), 29ft per minute (trolley), 17.5ft per minute (hoist). Typical applications include hardware maintenance and stores movement.

Another design is the Tensile Truss Crane that uses a triangulated three-part wire rope configuration. This design offers maximum stability when hoisted to the stowed position. Rotational stability is accomplished using the dual point lift versus single point. The versatility of this technology works well in LARS applications.

Benefits of Tensile Truss Cranes include:

- Much lighter weight than alternatives

- Can survive high sea-states without damage

- Can tolerate excessive side loads with little or no damage (self-limiting)

- Smaller equipment platform allows better accessibility to bulkheads and overheads

- Easier to clean and maintain, no hidden surfaces

- Able to reach to lower elevations if desired

Quality assurance in marine manufacturing facilities

PaR Marine manufacturing facilities operate under a quality assurance system certified to ISO 9001 and Mil-Q-9858A.

Product support by factory technicians for oil rigs and ships

PaR Marine backs up its products with a team of factory trained technicians who provide support on oil rigs and ships.