Midsund Bruk designs, engineers and supplies pressure vessels and storage tanks for offshore applications.

We use various design codes, such as PED, EN 13445, ASME U and U2, and PD 5500, as well as an array of welding technologies.

Pressure vessels for offshore and subsea operations

Midsund Bruk provides heavy carbon steel vessels such as P355/P500, vessels made in exotic steel such as stainless 316 L, duplex 22% Cr, super-duplex 25% Cr, 6Mo and Inconel 625/825, as well as titanium units. Some of our vessels require internal overlay cladding and post-weld heat treatment (PWHT), which is performed in-house.

We are in the process of establishing ourselves within the subsea segment by designing, fabricating and testing modules made of exotic steel. We also provide customised services for heavy steel projects.

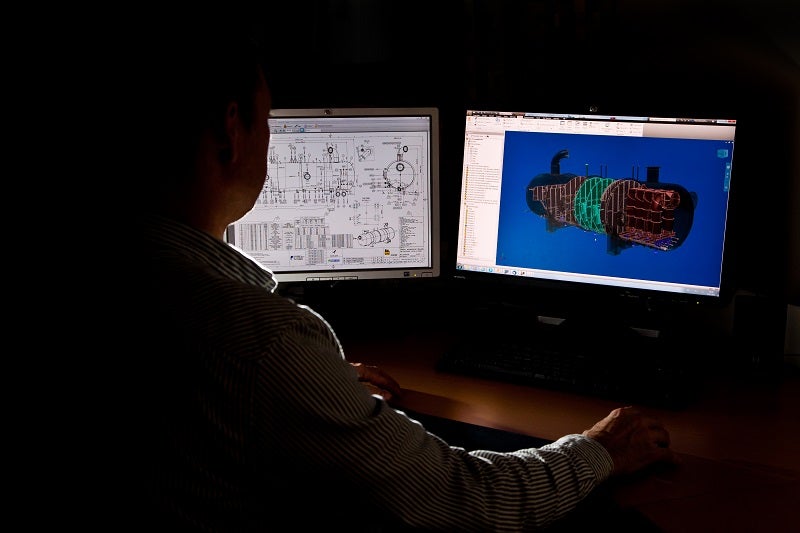

Front-end engineering services and nondestructive evaluations

Midsund Bruk serves its customers through front-end engineering design (FEED) and pre-FEED phases, based upon which we can provide cost estimates. Our team have the skills to carry out nondestructive evaluations (NDE) and surface treatment, which includes in-house NDE Level II/III and Frosio Level III.

This means we are a one-stop-shop for pressure vessels, including insulation, internal process equipment and external fixtures such as ladders and platforms.

Additionally, we perform reviews of third-party designs and follow up other fabricators on behalf of our customers.

Cutting machines, rollers and welding equipment

Our new Messer cutting machine cuts in three axes, using both plasma and gas (OxiFuel), and is linked directly to the 3D model. The same holds true for our sand and water machine. The Messer machine can cut 100mm duplex, whereas the sand and water machine cuts 250mm.

We have one of the largest rollers in Scandinavia, which has been newly upgraded. Our three rolling machines have a capacity of up to 150mm and the thickness depends on the width and material strength (E-module). Conical parts can be delivered if needed.

Midsund Bruk has a range of machinery, from tungsten inert gas (TIG) machines to large welding cranes (10m high and 8m long) for submerged arc welding (SAW). We are in the process of expanding our expertise in robotics and currently have one operational robot, with more to come.

Workshops and outdoor area with deep-water quays

Mudsund Bruk has three main workshops:

- Hall one – l04m by 25m with hook height of 12m and max crane capacity of 64t

- Hall two – l04m by 25m with hook height of 8/12m and max crane capacity of 100t

- Hall three – 60m by 30m with hook height of 27m and max crane capacity of 250t

We have workshops for specialist projects such as:

- Sandblasting and painting (32m long, 12m wide and 11 m high)

- Post-weld Heat Treatment (PWHT) (17m long, 11m wide and 7m high)

- Hall for Washing, pickling and passivation (25,5m long, 7m wide and 8m high)

Our 25,000m² outdoor area features a 75t portal crane and is used for storage and large-size operations.

The main quay is 6m deep and 50m long, but we can easily facilitate 15m depth using a barge for roll-on/roll-off at the north end. We are approved by the International Ship and Port Facility Security Code (ISPS).

About Midsund Bruk

Midsund Bruk is part of National Oilwell Varco (NOV) and can source products when needed, as well as delivering internals of all makes independently to stand-alone projects.

We use Visual Vessel Design (VVD), PVElite, ANSYS, FEMAP, AutoDesk Inventor, WeldEye and SharePoint in addition to standard Microsoft Office.