Inspectors.pl is a team of design engineers and inspectors providing project follow up on behalf of foreign customers. The founder and associated engineers’ ten years of experience in the offshore market serves as the company’s foundation. We specialize in complete fabrication and testing arrangements from market screening for suitable workshops to the dispatch of goods to specified destinations.

ENGINEERING EXPERIENCE

We employ devoted engineers with a minimum of ten years of background in heavy industry. They all come from positions of such as fabrication technologists and have an impeccable sense of technical feasibility, a key value when one has to turn a drawing into a fabrication process. Our team of eight such design engineers works with state-of-the-art computer aided design software (SolidWorks, Autodesk Inventor, ACAD Lt).

We have three design offices in various locations throughout Poland assuring quick access and short distances to all major industrial centers in Poland.

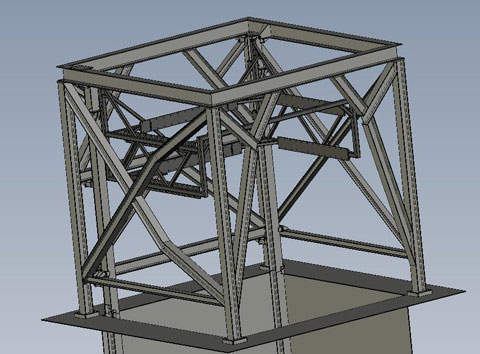

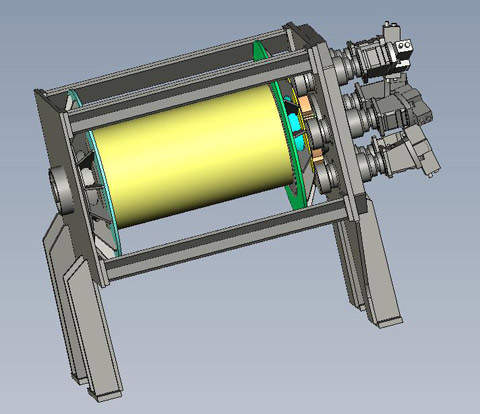

To date, we have worked with Norwegian companies providing specialized engineering solutions. For one such large project, we worked out the structural and mechanical elements of a subsea module handling system. Full details are available on our website.

FABRICATION AND TESTING OF EQUIPMENT

Testing equipment is obviously a critical part of fabrication and follow-up service. Whether contracted fabricators use their own technical resources and provide facilities for testing, or we have to make extra arrangements such as mobilizing hydraulic fitters and running Factory Acceptance Tests (FAT), we make sure that testing procedures are strictly adhered to.

Practically, we participate in all workshop preparations, inclusive of internal testing, to make sure that when customer’s representatives are invited, all items are in place and machines are running as designed. It is also our responsibility to ensure that HSE routines, as specified and used by customers, are implemented in the project quality plans, which are discussed and agreed to in the initial stages of a project.

During our years of handling offshore projects our team has supervised the fabrication and testing of equipment such as:

- BOP

- X-mass tree handling systems (cranes, skids)

- Vertical and horizontal pipe-handling systems

- Bridge cranes

- Cherry pickers

- Pedestal cranes

FABRICATION FOLLOW-UP AND COMPLETE DELIVERIES

Based on our knowledge of Polish industry and fabricators providing various services, we are capable of taking full responsibility for complete deliveries. Should a customer choose not to spend their time and energy on market study, we can play the role of substitute buyer who arranges all necessary services, inclusive of product certification by a classification society.

Thus we take all the worry and uncertainty off the customers’ shoulders. With our project management expertise and experience, we actively participate and assist in project handling, which comprises production planning, testing and inspection planning, and the creation of progress reports. These are essential communication tools that allow us to continually update the end customer.

We emphasize that we don’t select just any workshop for offshore fabrication. Thanks to our experience in the market, we enable customers to avoid the trap of well-structured and good looking web pages and promotion letters issued by inexperienced fabricators just entering this market.

Our inspectors also have the necessary experience and knowledge to organize auditing and QA systems.