Heerema Fabrication Group (HFG) specialises in the engineering and fabrication of large complex constructions, mainly for the oil and gas offshore industry.

The company’s wide range of services include design, fabrication, hook-up, project management, procurement and commissioning of offshore installations worldwide.

Integrated engineering services for the oil and gas industry

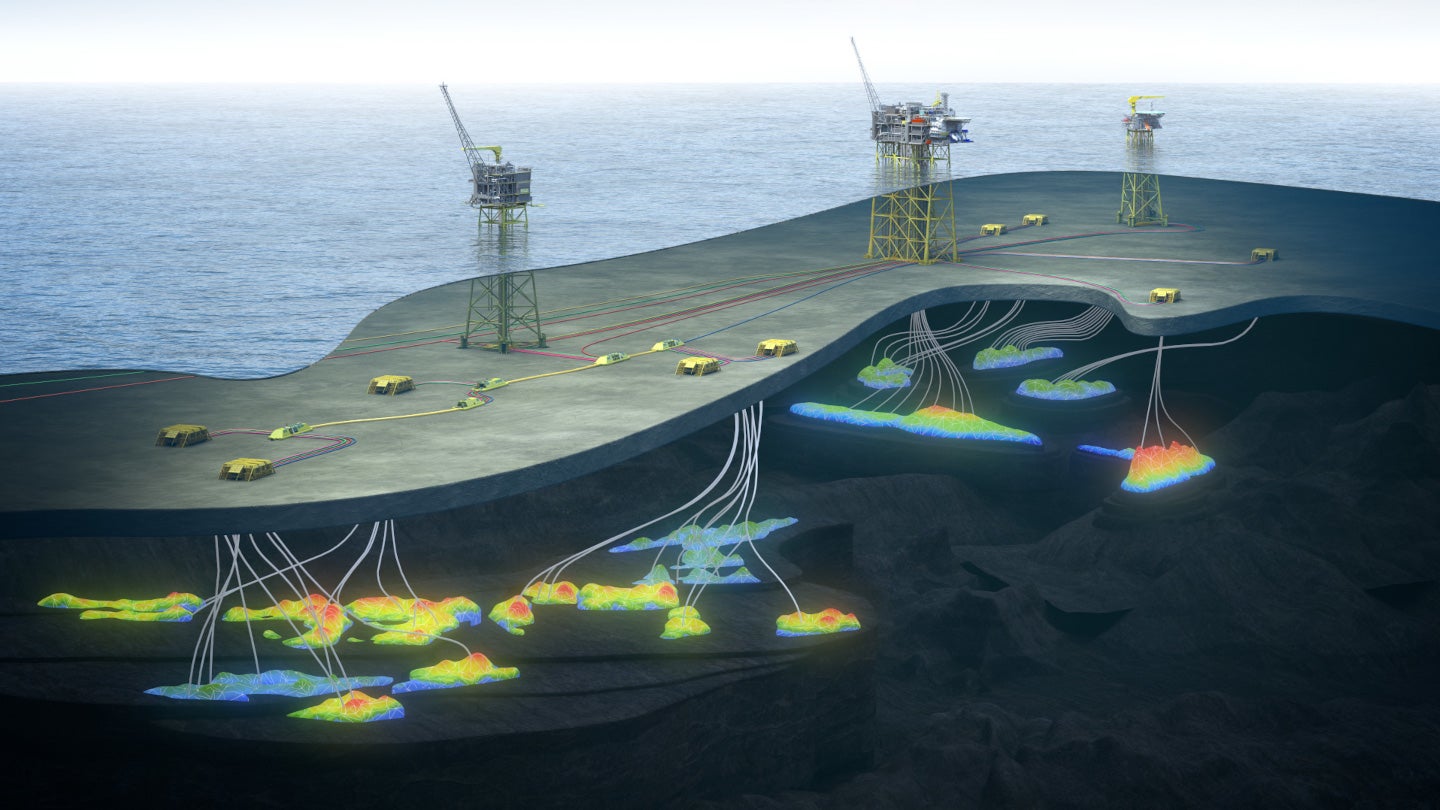

HFG supplies integrated project management and engineering services, which ensures the completion of all engineering, procurement, construction and installation (EPCI) contracts in the offshore oil and gas, and energy-related industries.

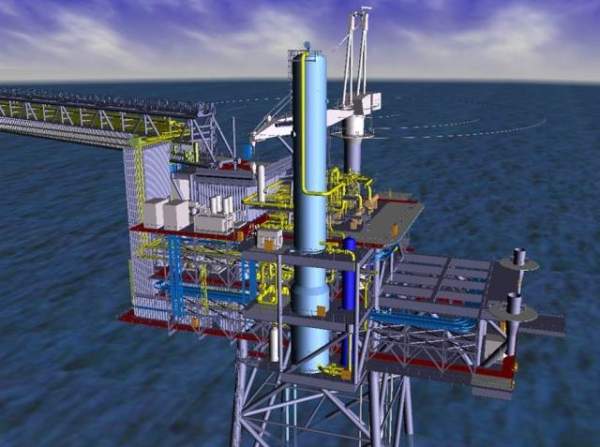

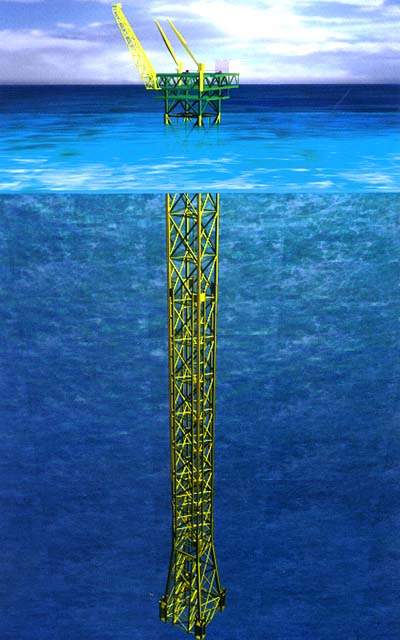

The company’s engineering department, HFG Engineering (HFGE), provides services with a focus on offshore facility design, with an emphasis on jackets.

The department specialises in fabrication-driven engineering and efficient designs, which optimise cost-efficiency and time of processes, as well as reducing associated fabrication safety risks.

Offshore fabrication facilities

HFG has a number of fabrication yards with facilities to build modules of up to 10,000t, as well as a multi-disciplined engineering department. The company focuses on the fabrication and EPCI contracting of jackets, topsides, modules, decks and topside integration projects.

HFG’s companies include:

- Heerema Zwijndrecht (Zwijndrecht, Netherlands)

- Heerema Vlissingen (Vlissingen, Netherlands)

- Heerema Hartlepool (Hartlepool, UK)

- HFG Engineering (Houston and Metairie, US)

Since 1964, Heerema Fabrication Group has fabricated platforms on the Dutch, Norwegian and UK Continental Shelves.

Quality assurance and safety standards

HFG continuously aims to surpass the expectations of its clients, while minimising the safety hazards on its installations and completing operations without a single incident relating to the environment, or health and safety.

HFG’s management system covers the combined activities of environment, quality assurance, health and safety, and security. It is designed to be compliant with the requirements of multiple international standards, including:

- EN 1090-1:2009 Execution of Steel Structures

- ISO 14001: 2004 Environmental Management Systems

- ISO 3834-2: 2005 Quality Requirements for Welding Metallic Materials

- ISO 9001: 2008 Quality Management Systems requirements

- OHSAS 18001: 2007 Occupational Health and Safety Management Systems

- PED 97/23/EC:1999 Pressure Equipment Directive (Hartlepool yard only)

- SCC**:2008/05 SHE Checklist Contractors (Dutch and Opole yards)