Brastec Technologies SA is a Brazilian-based equipment builder with a strong name for flexible pipe and cable manufacturing, handling and storage systems. Brastec designs, builds and supplies engineering solutions for the onshore and offshore oil, gas, telecom, and energy industries.

The company is deeply involved in the preparation of pre-salt exploration through the supply of equipment for flexible pipe manufacture, construction of onshore vessel supply bases, ROV launching and handling equipment and various types of testing systems.

Brastec provides its customers with preventive maintenance, including spare part planning, to ensure that operation and maintenance stay in tune.

Turnkey offshore design and engineering

Brastec is an engineering powerhouse with the turnkey supply of offshore design and equipment, where cost, automation and quality are a key competitive advantage. The company has an international technology network with joint ventures and technology partnerships, to supply local and international projects with state-of-the-art solutions.

Combining strong engineering departments with manufacturing has allowed Brastec to build turnkey testing and material-handling facilities. The company also has a dedicated R&D department to prepare itself and its clients for the next generation of equipment and products.

Oil and gas production lines

Brastec develops equipment capable of fully supporting oil and gas production lines, including:

- Extrusion lines for flexible tubes

- Carcass lines for metallic and composite flexible tubes (framing)

- Armouring lines for metallic and composite flexible tubes

- Line for the application of metallic shielding for flexible tubes (Flexlock)

- A complete range of custom testing equipment such as dynamic testing chambers (tension, pressure, vortex induced testing, bend and twist, and hyperbaric test chambers)

Onshore and offshore equipment manufacture

Brastec specialises in the engineering and manufacture of onshore and offshore equipment. This includes delivering complete projects from development to delivery and meeting the standards of the competitive oil and gas market.

Brastec is able to provide various types of heavy equipment, designed and manufactured with advanced technology in the most complex materials.

With its in-house engineering and assembly staff, Brastec is fully prepared to serve the market with innovative solutions that include the turnkey supply of equipment, international field support and development of next-generation solutions. The company has the experience and expertise to supply complete manufacturing plants.

Pipe launching systems

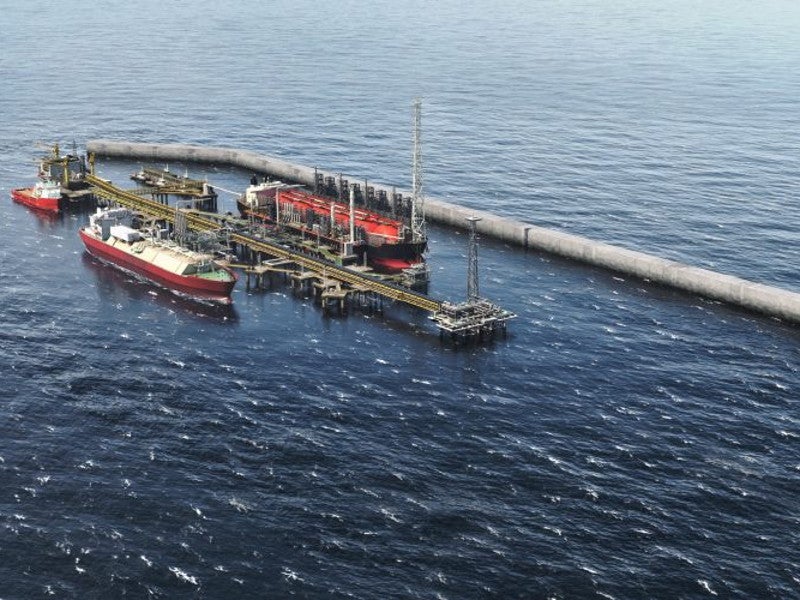

Brastec supplies equipment for the offshore industry, which includes complete pipe laying systems (S and J lay) as well as storage baskets and carousels for vessels. Systems up to a capacity of 400t can be custom developed for different application needs.

Flexible pipe and umbilical cable manufacturing systems

Brastec is a full service supplier of equipment for the manufacture of flexible pipes and umbilical cables. These systems include all process steps from carcass, armouring and pressure vault manufacturing up to extrusion systems and pipe-handling equipment. Brastec is also involved in the development phase of the customer’s products, with testing and simulation systems.

Brastec designs and develops machinery for the manufacture of flexible pipes and umbilical cables, and equipment geared for the storage and handling of flexible tubes. All equipment is designed utilising 3D design methods and finite element analysis to guarantee a proper dimensioning and functionality during its design life.

Offshore expansion

Brastec is currently expanding its presence in the offshore market, with a strong focus on pipe-laying vessels and related equipment. With experience with tensioners, carousels, spooling systems and subsea support equipment, Brastec is developing strong name recognition in this market.

Brastec Technologies history

Brastec was established in 2002 and is nationally and internationally recognised as a major player in its business segment. Today, its headquarters and manufacturing plant are located in Jundiaí, in the interior region of São Paulo state.