Adaptive Engineering Services (AES) provides engineering services and products to the oil and gas industry, focusing on offshore systems and deep-water applications.

AES provides its customers with turnkey system solutions and expertise in design, engineering, testing, ABS and DNV certifications, procurement, construction, quality control, installation, maintenance and repair of offshore and subsea systems.

Offshore and marine systems

Through its applied technology and fabrication expertise, AES provides a wide range of integrated engineering services and turnkey offshore systems, including:

- ABS and DNV certification

- Diving support vessel (DSV) work platforms

- Offshore construction

- Subsea pipeline monitoring and data control systems

- Subsea pipeline systems (steel and HDPE pipelines)

- Subsea sensor systems

- Subsea tooling for remote-operated vessel (ROV) intervention

- Surface diving systems

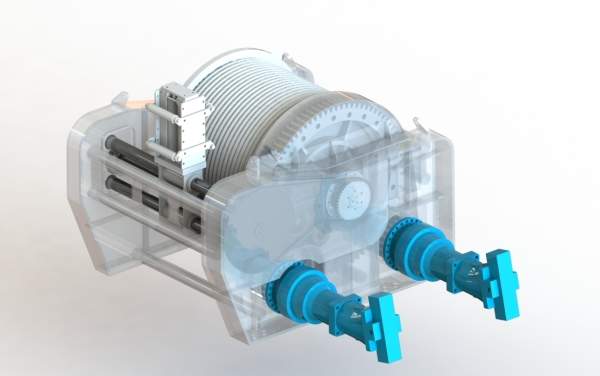

- Saturated diving winches (ABS and IMCA certified):

- Diving bell winch (21,000lb safe working limit (SWL))

- Guide wire winch (29,000lb SWL)

- Umbilical winch (3,000lb SWL)

- Man riding winches for surface diving operations (2,500lb to 7,500lb SWL)

- Saturated diving systems rated for 1,000ft of sea water (fsw) (300msw):

- Diving bell

- Transfer under pressure (TUP)

- Deck decompression chambers (DDC)

- Human rescue chambers (HRC)

- HRC emergency deployment systems

- Handling systems, A-Frame and trolley systems

- Tool davit

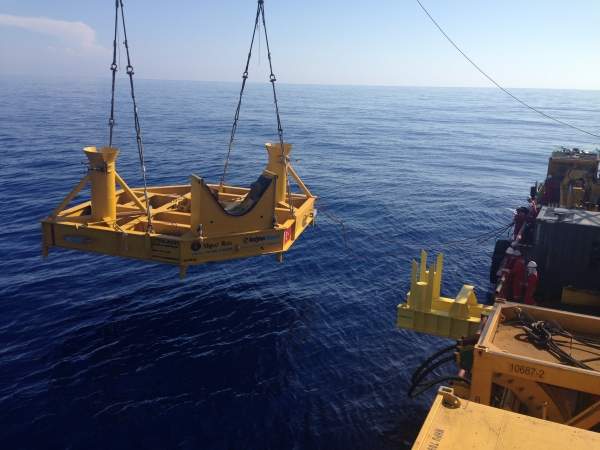

Offshore and subsea engineering projects

AES’ team of engineers, specialists and technicians are involved from the initial project plans to the finished product, including the onsite installations, testing and commissioning phases. The team ensures that the delivered solutions result in a cost-effective, efficient, high-quality service.

AES acts as an extension to its customers’ technical, engineering, testing and procurement departments, in order to facilitate quick product development and an efficient transition into production.

With more than 25 years of experience, AES executes successive research, development and innovation in its daily engineering tasks and operations for future projects. The company’s technical and support team provides a broad range of project management and detailed engineering services.

AES’s range of facilities includes:

- 3D modelling

- ASME pressure vessels designs using Cosmos

- Cathodic protection

- Certification

- Commissioning

- Concept development

- Design validation and testing

- Fabrication

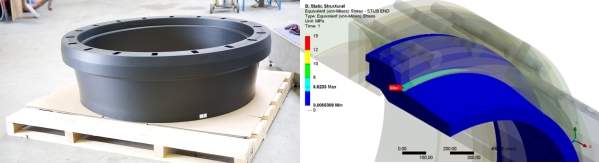

- Finite element analysis (FEA) using ANSYS

- Hand calculations

- Hydraulic system and circuit designs

- Piping and flow calculations

- Preliminary and complete design documentation

- Project management

- Prototype development

- Quality control

Offshore development projects

AES has conducted expansive engineering and construction works for offshore technology development, which include:

- The design, detailed engineering, prototype fabrication, design verification and ABS certification services for the development of Y-Piece and steel to high-density polyethylene (HDPE) joints for the 80km-long offshore crossing of the TRNC Fresh Water Pipeline Project

- The design and supply of 300msw-rated subsea sensor and monitoring system for the TRNC Fresh Water Pipeline Project

- The delivery of seven 1,000fsw-rated saturation diving system projects to clients in the Gulf of Mexico and Middle East

- Provision of engineering, mobilisation and certification services for DSV and offshore supply vessels (OSVs)

- The supply of ROV intervention components for pipelines

In between large-scale projects, AES has undertaken design, engineering and certification contracts for offshore and marine applications.

Project risk management

Understanding and evaluating the risks associated with offshore and subsea operations is a specialist business requiring a thorough knowledge of this complex industry. AES understands the requirements of the industry while performing risk management during each phase of the project.

With its wide experience and skillsets built on completed turnkey custom solutions, AES knows what it takes to deliver unique solutions in short lead times.