ZINGA is a protective coating that has been produced and commercialised by Zingametall in Belgium for more than 40 years, during which the company has gained technical expertise and extensive knowledge in galvanic protection.

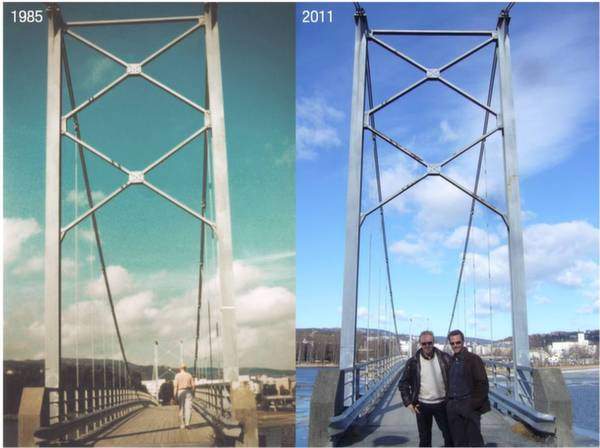

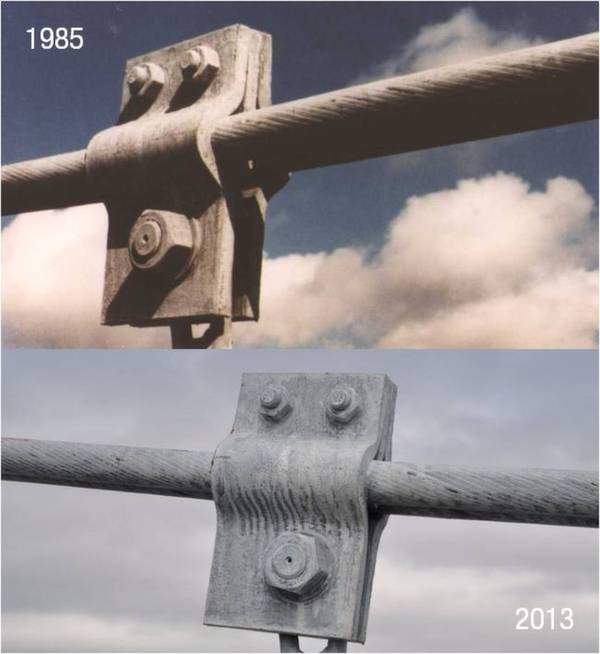

In numerous field tests, project applications and standardised testing, ZINGA has proven to provide active, long-lasting and sustainable protection to steel structures worldwide.

Galvanic protection coating for offshore structures

ZINGA is a one-component, film-galvanising system containing 96% zinc (dust) in its dry film. It is a metallic coating rather than a paint. The purity of zinc used is so high that dry ZINGA does not contain any toxic elements.

The zinc in the coating (anode) protects the steel in a comparable way to hot-dip galvanising. Upon impact, the electron flow from a potential difference between zinc and steel will prevent the latter from corroding.

As the ZINGA oxidises, a layer of zinc salts slowly builds up on the coating’s surface, closing the film and enhancing the barrier effect.

Protection of a wide range of steel structures

ZINGA provides protection without the need for topcoats.

ZINGA can be used in duplex systems (active + passive layer), where it is overcoated with a compatible paint. The additional protection of the topcoat significantly increases the durability of the system.

Although ZINGA is only available in grey, its significant advantage is that it can be reapplied in the future with minimal preparation and without compromising its integrity. ZINGA is often used on its own, because the structure is already on site or too big for molten zinc baths.

Re-liquidising coating for easy maintenance

Another of ZINGA’s unique characteristics is its ability to re-liquidise when a new coat is applied onto an existing layer to form a single homogeneous layer.

This ensures massive cost saving in ongoing maintenance because the old ZINGA layer does not need to be removed before re-coating with a new layer, although a removal of contaminants is required.

Standardised, anti-corrosion testing

Over the last 30 years, ZINGA has undergone numerous anti-corrosion testing at different certified laboratories worldwide.

All testing was according to local and international standards, including:

- ISO 12944: ZINGA 2 x 90 µm DFT – C5 I/M High

- NORSOK M-501- syst. 1 and 7: ZINGA 2 x 60 µm DFT – passed

- ASTM B-117 (Salt spray): ZINGA 2 x 90 µm DFT – more than 4,200 hours passed

Approvals and certifications

In consequence of ZINGA’s performance (proven by testing), ZINGA has been approved for use by governments, companies, armies.

The most important include:

- Lloyd’s Register (Approval for use in void spaces)

- European Technical Approval (Europe)

- Approval by APAS (Australia)

- Registration by Petrobras (Brazil)

- Approval by Ministry of Transport (Canada)

- Approval by Czech Railway (Czech Republic)

- Approval by Engineers India Limited (India)

- Approval by Statoil (Norway)

- Approval by CFE (Mexico)

- Approval by Agrement Technic (Romania)

- Approval by Land Rover (UK)

- Approval by Crown’s Castle (USA)