Rysco Corrosion Services is a Canadian-based oilfield service company dedicated to providing internal corrosion monitoring solutions to onshore and offshore oil and gas producers. Primary services include solutions relating to threaded and hydraulic access fitting field service, electronic monitoring (ER, LPR, Galvanic), monitoring equipment supply and specification, weight-loss corrosion coupon analysis, and sessile / planktonic bacterial sampling and reporting.

Additional services include field sampling (water, Fe/Mn, CI residuals) and onshore pipeline external coating inspections via ACCA, ACVG, DCVG, and CIPS.

Rysco Corrosion Services can provide audit services related to internal corrosion monitoring and production specialty chemical usage. Proper monitoring should ensure that all mitigation strategies have the potential to be evaluated.

The company employs educational resources to provide access to sophisticated analytical equipment to provide innovative solutions related to corrosion and specialty chemical monitoring.

Equipment supply and specification: access fittings, hydraulic access fittings, electronic probes

In addition to determinating monitoring locations, equipment selection and specification is one of the most important elements of internal corrosion monitoring. There can be many different configurations of internal corrosion monitoring tools. The most common configuration for the insertion of corrosion monitoring equipment is access fittings.

Access fittings are available in many mounting configurations and are a suitable alternative to retractable and plug coupon holders. Primary advantages to access fittings are the ability to place monitoring in exactly the same position in subsequent pulls, the easy exchange of weight-loss corrosion coupons for electronic monitoring, and the ability to retrieve the monitoring equipment without isolation and minimal pipeline depressurisation from the equipment.

Access fittings are available in many mounting configurations (flanged, butt weld, flare weld) and various metallurgies. A significant advantage to access fittings over retractable and plug coupon holders is the ability to collect flowing produced water samples while the pipeline remains online.

Internal corrosion monitoring field service: coupons, probes

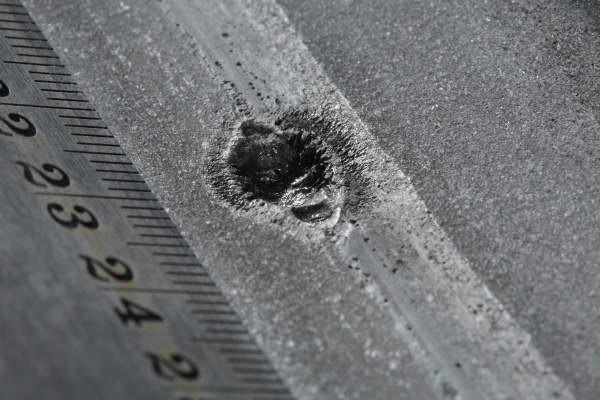

Weight-loss corrosion coupons (mechanical) and probes (electronic) are suitable complementary methods for monitoring internal corrosion.

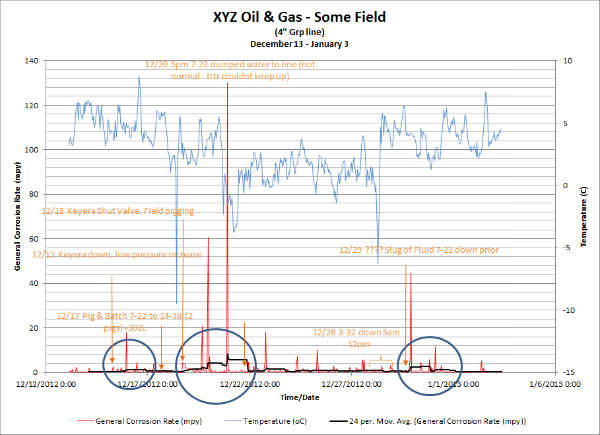

Rysco Corrosion Services supplies, installs and services the most common commercial products available, including coupons, electrical resistance (ER), linear polarisation resistance (LPR), and galvanic probes. The primary advantage to electronic monitoring is the ability monitor corrosion events in close to real-time capacity (i.e. hourly intervals), versus the time weighted average reported with weight-loss corrosion coupons.

Electronic probes can be configured to read online, remotely, or via client SCADA system with 4mA-20mA interface.

Bacterial sampling: sessile / planktonic SRB / APB

Bacteria can be a mechanism in corrosion in oil and gas production, and is commonly referred to as microbial influenced corrosion (MIC). Rysco Corrosion Services is able to provide sampling, inoculation, and reporting for the most common types of oilfield bacteria.

The accepted standard for bacterial testing in oilfield produced water is serial inoculation via dilution.

Rysco Corrosion Services is able to test for planktonic (free floating) and sessile (attached) sulfate reducing bacteria (SRB) and acid producing bacteria (APB) through this method. Techniques employed adhere to NACE TM0194 ‘Field Monitoring of Bacterial Growth in Oil and Gas Systems’.

Additional bacterial testing may be completed through the utilisation of BART™ tests to identify iron-related bacteria (IRB), sulfate reducing bacteria (SRB), slime forming bacteria (SLYM), heterotrophic aerobic bacteria (HAB), denitrifying bacteria (DN), nitrifying bacteria (N), and acid producing bacteria (APB).

Field sampling: produced water, solids, Fe / Mn, corrosion inhibitor residuals

Produced water chemistries can be used as a valuable tool in monitoring internal corrosion on pipelines. Full water analysis, Fe / Mn concentrations, and corrosion inhibitor residuals can provide indications as to the corrosiveness of oilfield produced water, or the effectiveness of corrosion inhibitor programmes (mitigation).

Proper sampling of waters for representativeness and technique is equally as important as good lab analysis on the supplied produced water sample. Rysco Corrosion Services adheres to API RP 045 ‘Recommended Practice for Analysis of Oilfield Waters’ for sample collection of produced water sampling.

Novel techniques for sample analysis

Rysco Corrosion Services is currently researching and evaluating novel techniques for the quantification of oilfield samples related to corrosion mitigation by the addition of corrosion inhibitors.

Specifically, Rysco is evaluating alternatives and complimentary testing related to corrosion inhibitor residual analysis (both batch and continuous applications), and surface evaluations (CID – copper ion displacement alternatives).

Audit services – monitoring and specialty chemical programmes

Rysco Corrosion Services Inc is able to provide audit services for the evaluation and presentation of recommendations related to existing and proposed internal corrosion monitoring programmes.

These audits can be complemented with audit services for the evaluation and presentation of recommendations related to existing and proposed production specialty chemical programmes.

Please contact us with your business enquiry.