Presserv is a globally known and respected company in the field of corrosion protection and control. Established in the UK in 1998, Aberdeen-based CSL specialises in the supply and application of vapour corrosion inhibitors (VCI) and vapour-phase corrosion inhibitors (VpCI).

Although based in the UK, Presserv is called on worldwide to both supply and manage corrosion protection projects for clients. We can help with anything from the supply of a single box of inhibitors to writing a full preservation manual, to supervising or managing the preservation element of your project on-site. We are registered with FPAL number: 10043473.

We are respected providers of corrosion inhibitors, preservation services, vapour corrosion inhibitors, vapour phase corrosion inhibitors, VPCI, VCI, equipment preservation, corrosion control, process inhibitors, pipe preservation, electrical preservation, mechanical preservation, rotating equipment preservation, and deluge preservation.

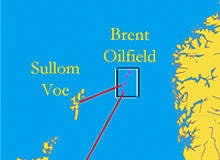

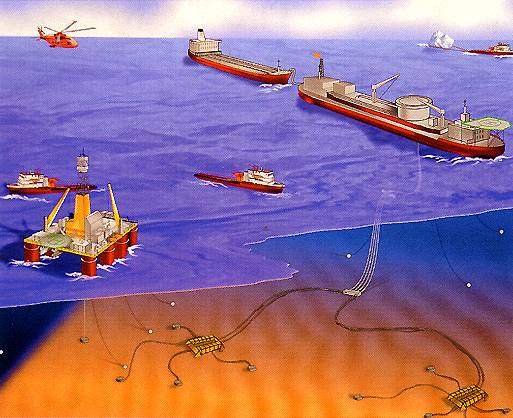

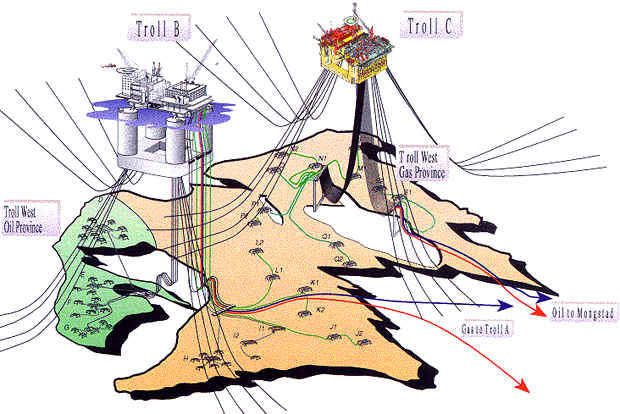

Corrosion inhibitors for the offshore industry

Presserv has been an approved Cortec distributor since 1998. We are the oil and gas distributor in the UK and Kazakhstan for the Cortec range of corrosion inhibitors, and can supply these products to almost any country.

Cortec Corporation of Minnesota, US, is the world leader in VpCI technology. Over the last 40 years, the Cortec range of corrosion inhibitors has been very successfully used in the North Sea and beyond.

Inhibitors for offshore corrosion prevention

The range of corrosion inhibitors available is endless. For oil and gas applications, we provide inhibitors and processes for electrical equipment, hydro-testing, mothballing and lay-up; inhibitor additives for process streams, deluge cleaning, and preservation; high-performance inhibited coatings and general bolt preservation.

Vapour-phase corrosion inhibitor (VCI) technology

There are countless manufacturers of vapour-phase corrosion inhibitors (VCIs) or products claiming to be VCIs (able to protect in gaseous / air phase without physical contact of chemical). Some work effectively, some do not.

In response to the bad name VCIs were getting due to many products not performing as a VCI should, Cortec renamed its products VpCI, trade-marking the term ‘VpCI’ so that no-one else can claim to manufacture them. If you want to make sure a vapour-inhibiting chemical is effective, insist on using a Cortec VpCI.

VpCI technology for the offshore industry

Cortec’s range of proven VpCI technology works by emitting a vapour that forms a layer on metal surfaces at a molecular level. This layer is self-replenishing (you can open and close boxes / enclosures), and will prevent or reduce corrosion activity down to acceptable levels. Some of Cortec products are listed as follows:

- Cortec VpCI-101 foam pads for JBs and small packages

- Cortec VpCI-111 emitters for large electrical enclosures of packages

- Cortec VpCI-609 powder for hydrotest applications or VpCI-609S for dry fogging

- Cortec VpCI-368 inhibited wax coating

- Cortec VpCI-329/322 oil additive

- Cortec M-528 additive for synthetic fluids

- Cortec VpCI-126 / Corpak film polythene for wrapping

- Cortec VpCI-Corrlube inhibited grease coating

- Cortec GalvaCorr, a new concept in cathodic protection

- Cortec VpCI-422 biochemical rust remover

Economical vapour-phase corrosion inhibitors

Cortec also produces a range of EcoAir (air-powered aerosol) and EcoLine (soybean derivatives) vapour-phase corrosion inhibitors. The list is exhaustive so please contact us for information or advice.