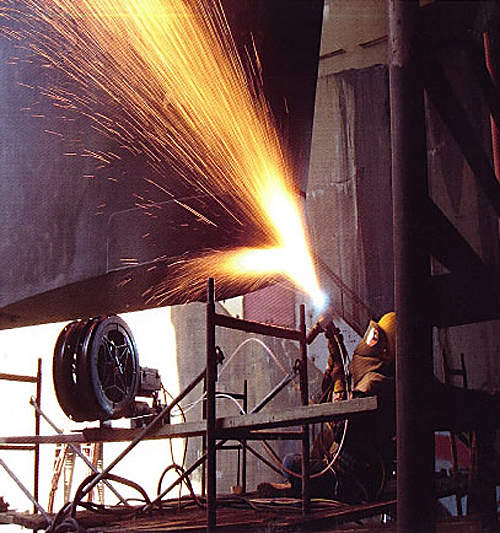

Protecting steel in the offshore industry is essential as corrosion can slowly destroy your most important assets. With advancements in thermal spraying technology, metalizing has emerged as the best corrosion protection solution available.

MTM Metalizing is a joint venture set up with International Metalizing & Coating (IMC), which has been in thermal spray application business since 1995. We use IMC’s patented electric arc spray technology, which meets demanding specifications for quality, durability and speed of application.

We provide customized solutions to corrosion problems in the marine, petrochemical, structural steel, rail and infrastructure industries. Our technology has been approved and used in a variety of corrosion-prevention projects for high-profile clients, including Panama Canal Authority, NASA, the US Navy, the New Jersey Department of Transportation and the American Bureau of Shipping (ABS).

Metalizing for offshore corrosion protection

Metalizing is a process by which a metallic coating is deposited on to a surface. In use for the last 100 years, studies prove that metalizing is the best corrosion fighting system in the world.

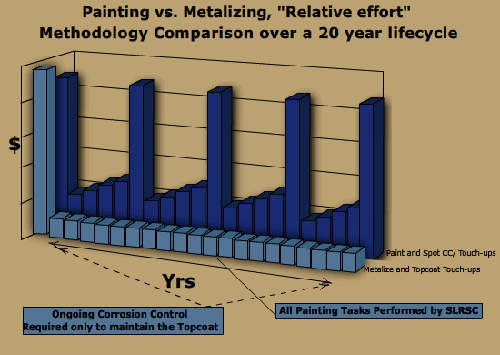

With MTM Metalizing’s process, previous application problems when using old metalizing methods have been overcome. No matter what the environment, our metalizing solutions deliver long-lasting protection for equipment with minimum trouble and expense.

Metalizing has been protecting steel for more than 30 years. Delivering an unmatched service life, metalizing provides a much lower lifecycle cost and an upfront project cost that is competitive with conventional coating.

Metalizing machines for corrosion protection

Our metalizing machines are manufactured by IMC in New Jersey, US, and registered with the US Patent Office and the Paris Convention of Countries. They are extremely compact, light and portable, measuring 40cm high, 80cm long and 36cm wide, and weighing no more than 20kg.

These machines are capable of spraying wire diameters up to 4.76mm. Fast deposition rates of more than 100m²/hr at 250µm thickness can be achieved, which exceeds airless paint systems.

Any metal that can be put in wire form can be metal sprayed with these machines. They can also apply different metals at the same time to form an instant alloy. Rough or smooth surfaces can be produced by varying air pressure, along with an adjustable spray pattern for small or large applications.

ABS-approved zinc and aluminum metalizing

Micrograph studies substantiate that the metalizing process is the only thermal spray application that has no porosity. The ABS has issued certifications for zinc and aluminum applications performed by these machines.

Metal-sprayed zinc coating for vessels

After extensive testing, including accelerated corrosion tests, DNV has given type approval under IMO / PSPC requirements for metal-sprayed zinc coating, applied by MTM Metalizing, to be used for ballast tank coatings for vessels.

DNV’s approval is considered to be the first issued under the IMO guidelines. Due to the application speed of IMC’s equipment, metalizing can be used as a realistic alternative for ballast tank coating for the first time.

Aluminum and zinc-form anodic coating

Aluminum and zinc-form anodic coating protects against corrosion for many years. Aluminum ensures a heat-resistant coating that can withstand cyclic heat application of up to 600°C. By using arc spray instead of the flame spray process, the application rate is vastly increased, as is the quality of the coating.

Through the selection of the metal to be sprayed, multiple types of protection can be attained. For example, Inconel can provide a seawater / erosion-resistant coating for marine applications, while other wear-resistant coatings can be achieved with aluminum or nickel-based coatings.

Metalizing for marine applications

MTM Metalizing provides metalizing for the following marine applications:

- Tank linings

- Anti-fouling

- Anti-corrosion

- Exhaust stacks

- Steam pipes

- Non-skid decking

- High-abrasion areas

- Chain lockers

- Process equipment

- Ballast areas

- Potable water tanks

- Fuel tanks

- Super structures of any vessel

On-site metalizing for the offshore industry

With the latest advancements of the IMC patented application technology, our process can be conducted on-site and is not just confined to blasting and spraying chambers. Our metalizing machines are compact and mobile, and designed for difficult-to-reach areas. The fast application rate of our equipment enables us to complete large area jobs within tight schedules.

Metalizing requires a short set-up time and dry, clean air pressurized at around 125psi and 185cfm. Our metalizing unit consists of metalizing wires, patented metalizing machines (ASMM and RedDevil) with wire feeder and feed tubes, heavy-duty electric cables, a moisture separator, 19mm (3/4in) air lines and fittings.