Metallisation’s commitment to continuously improving and developing its technologies has led to the release of the new 145 Metal Arcspray System.

The device is able to achieve a finer, denser coating than ever before thanks to increased airflow through the pistol.

The 145 system also features digital display meters, the latest level PLC, incoming power supply MCB’s, reversible (twice the life) V-rollers to ensure the most reliable wire feed possible, as well as a remote operation capability.

It also features an optional data kit to feedback spray data to a host PLC, giving the possibility of remote monitoring and logging of certain energiser data at a customer’s HMI via a Siemens S7-1200 series CPU, thus ensuring you the best quality coating possible.

Some areas of application where MSSA products are used in the oil and gas Industry include:

- Thermal Sprayed Aluminium (TSA) & Thermal Sprayed Zinc (TSZ) for Anti Corrosion protection of Oil Rigs, Flare Booms, Corrosion Under Insulation (CUI)

- Anti -slip flooring coating applied by Arcspray

- The system can also be used with a wide range of Engineering materials that can be used to reclaim / restore worn parts

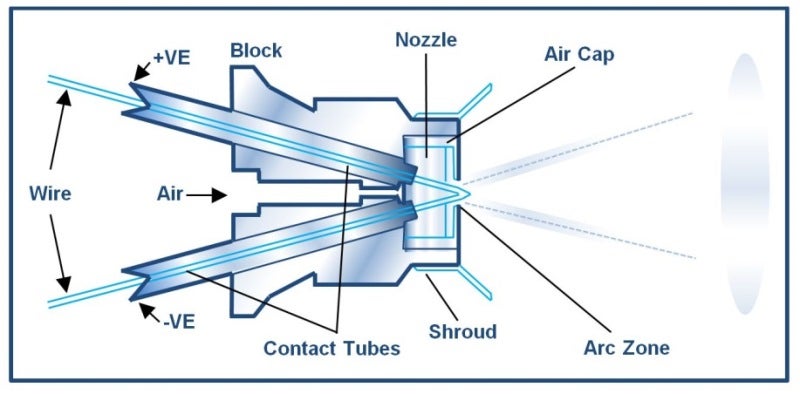

The Arcspray Process

In the Arcspray process the raw material, in the form of a pair of metallic wires, are melted by an electric arc.

This molten material is atomised by a cone of compressed air and propelled towards the work piece. Aluminium is particularly suited to arc spraying as this process can give coating bond strengths in excess of 15MPa.

Combined with the excellent performance of aluminium in saltwater environments, arc sprayed aluminium is a very common process / material combination in the marine and offshore industries.

For more information, please contact Metal Spray Supplies Australia via the enquiries form.