DISTIXX® is an ISO 9001:2008-accredited manufacturer of flange protection products for the industrial market.

DISTIXX is headquartered in the Netherlands with an Indian branch, DISTIXX Protectors, which was established in 2010 to meet demand from the fast-growing Indian market.

DISTIXX works in partnership with its customers and continually seeks to provide new solutions for new challenges. We strive to meet your asset integrity requirements – whatever they are and wherever they may be.

Flange face protection products

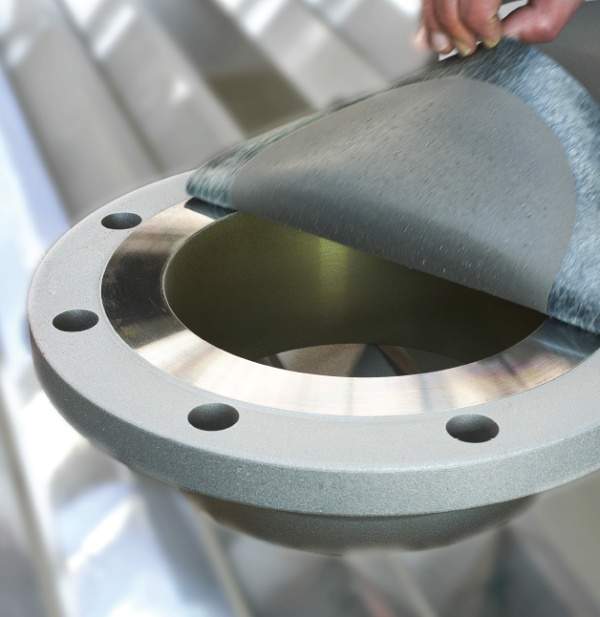

Our core business is the development and manufacture of self-adhesive DISTIXX products for full flange face protection.

We use advanced CNC production machinery and work in close cooperation with leading European rubber and adhesive producers to develop products that meet evolving product specifications.

DISTIXX flange protection products are used worldwide in a variety of industries, including oil and gas, petrochemical, paper and pulp, food, water, nuclear power and renewable power.

Vulnerable surface protection

DISTIXX products are designed to meet the stringent requirements of the industrial marketplace. They combine high-quality NBR-based rubber and a specially developed adhesive that leaves no surface residue when removed.

Our asset integrity range includes flange faces on valves and pumps, pipes, turbines, engine parts and any other vulnerable surfaces that require protection during blasting, painting, storage or transportation.

Features of DISTIXX self-adhesive flange protection products

DISTIXX self-adhesive flange protection products come in all shapes and sizes and take just seconds to apply and remove. They save you time and money, offering 100% protection during blasting, painting, transportation and storage. They are chloride-free and oil and weather-resistant, and will not deform – even in rugged environments. They can withstand a temperature range of -20ºC to +60ºC.

Applications for surface protection products

DISTIXX surface protection products are designed to mitigate damage to valve facing and equipment, providing significant time savings during shutdown, maintenance or commissioning. They are also used to prevent damage to valves and equipment during transportation.

To find out how they can be used in your operations, please contact us using the details or enquiry form below.