Armacell specialises in flexible technical insulation materials and is the inventor of the Armaflex, the first flexible foam insulation for pipes, ducts, vessels etc.

For more than 60 years, Armaflex® Insulation Systems have been implemented in a wide range of projects worldwide.

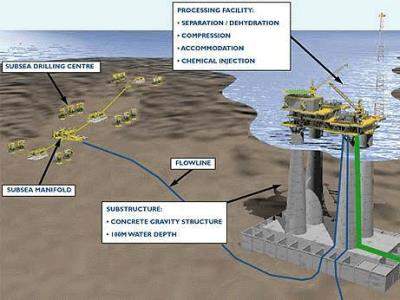

The Armacell Engineered Systems oil and gas division offers specially designed, cost-effective thermal and thermal-acoustic insulation systems for Oil and Gas industries.

Mitigation of Corrosion Under Insulation (CUI)

Corrosion under insulation (CUI) causes catastrophic failure and extended downtime. It is estimated that 40 to 60% of pipe maintenance expenditure is down to CUI, costing the oil and gas industry around $1tn a year worldwide.

The right choice of insulation can significantly reduce downtimes and maintenance costs. A test conducted by TNO / Endures (Netherlands) has confirmed that Armaflex insulation systems minimize the risk of CUI.

The test confirms the excellent results achieved with Armacell’s elastomeric insulation materials all over the world.

Comprehensive sound control and thermal insulation system in a single system

ArmaSound Industrial Systems provide the required noise control and protection against condensation and moisture penetration.

The system is available in different configurations with various insulation layers and thicknesses, each designed to meet target noise requirements.

When compared with traditional insulation constructions, ArmaSound Industrial Systems are fully compliant to ISO 15665 with reduced insulation thickness and weight.

Key benefits of ArmaSound Industrial Systems include:

- Reductions in space (up to 60%) and weight (50%)

- Installed cost saving up to 30%

- Reduced maintenance time and costs

- Improved health, safety, environment and system life expectancy

- ISO 15665, Norsok R-004 and ASTM E1222 compliant

Maintenance-friendly thermal-acoustic insulation systems

If thermal-acoustic insulation is required on low-temperature installations, the combined use of Armaflex Cryogenic and ArmaSound Industrial Systems is recommended.

The dust and fibre-free systems are easy to install and designed to work together to reduce total installation and maintenance costs.

Low-temperature flexible insulation systems

Armaflex Cryogenic Systems are specially designed for low-temperature applications (down to -180°C).

The systems ensure excellent thermal insulation and decrease the risk of CUI, and may not require additional vapour barriers or contraction joints.

Key benefits include:

- Flexible, even at low temperatures

- Reduced risk of crack development and propagation

- Contraction and expansion joints may not be required

- Easy to install

- Low density and weight

- Cost effective

Polymer-based covering material to minimise risk of CUI

Arma-Chek R is a flexible polymer-based, installation-friendly covering that provides extra system security to further reduces the risk of CUI in harsh environments.

It is fully weatherproof and highly resistant to water vapour, UV radiation, oil and chemicals, and its non-metallic nature eliminates the risk of galvanic damage and corrosion.

About Armacell Engineered Systems

With 23 manufacturing plants in 16 countries across four continents, Armacell Engineered Systems provides an efficient delivery service and supplies large industrial projects from multiple sources.

Local sales representatives, technical consultants and application specialists are available to support facility operators, designers and insulation contractors.

Armacell’s insulation systems have been specified for ventures operated by some of the leading international oil and gas companies, such as Shell, BP, Total and Chevron. Previous projects include the Schiehallion FPSO (1997), the Terra Nova FPSO (1999), Sakhalin (2005), the Snøhvit LNG terminal (2005), the Sonatrach Skikda LNG project (2010), Dalian (2011), Claire Ridge (2015) and Ichthys (2015).

Armacell’s products are certified according to international fire standards, including those of the International Maritime Organisation (IMO), Lloyd’s, DNV and the American Bureau of Shipping (ABS). Further information is available upon request.