Since 1969, Accoat has been a core provider of surface solutions to a vast range of industries worldwide. Its clients include companies from the offshore, petrochemical, heavy chemical, pharmaceutical and foodstuffs industries.

Accoat is a subsidiary of SP Group, a Danish organisation listed on the Nordic Stock Exchange in Copenhagen. SP Group has subsidiaries in several countries and employs over 700 people.

Advanced corrosion protection production facilities

Accoat’s headquarters with its 9,000m² production facility is based in Kvistgaard, 40km north of Copenhagen.

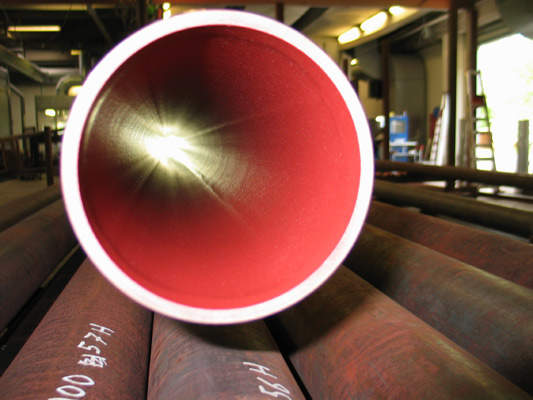

Accoat’s second plant, in Stoholm, Jutland, with its 1,800m², is specifically intended for the automated coating of downhole production tubes, while its transport system can handle up to 40t. The plant carries out internal sandblasting pretreating processes for tubing, and the sinters ovens’ capacity is 14m x 3.2m x 3.2m.

Additionally, in 2010, Accoat has established a coating facility of 800m² in Brazil, which is located in the proximity of Sao Paulo in Sorocaba.

Downhole production tubing

Accoat is a partner in marketing DuPont™ StreaMax™ flow solutions for downhole production tubing. Moreover, Accoat is a first choice as an applicator of internal coating in the North Sea region.

DuPont™ StreaMax™ is a registered trademark of DuPont®. StreaMax® is a coating especially developed and designed to maximise well productivity and to minimise operation and maintenance costs.

High-quality corrosion protection and flow enhancement

Accoat’s ability to deliver efficient services is confirmed by the certifications that the company has received. The production plants in Denmark are certified by:

- The quality standard DS ISO 9001:2008

- The environmental standard DS/ISO 14001:2004

- Qualified supplier in the Joint Qualification System (JQS), Achilles. Ref. no. 26762

Accoat is your surface solutions provider when you need:

- Flow enhancement

- Non-stick

- Low friction

- Corrosion protection

Our further capabilities include:

- Development and customisation of coating processes

- Handling and managing large and heavy items

- Flexible and versatile production facilities

- Supplying to customers worldwide

DuPont™ StreaMax™ coating for downhole production tubing

- Maximise productivity

- Minimise maintenance costs

- Non-stick

- Flow enhancement

Application to the internal coating of oil tubes.

Accotron wear-resistant coating

- Hard, wear resistant

- Chemical resistant

- Corrosion-protective

- FDA approved

Applications – valves, pumps and reaction vessels for the chemical industries.

Accoshield non-stick coatings

- Reduced coefficient of friction

- Non-stick

- Chemical resistant

- Temperature resistant

Applications – reaction vessels, pipes, pumps and valves for the chemical industry.

Accopon / Accolan chemical-resistant coatings

- Reduced coefficient of friction

- Wear-resistant coating

- Non-stick

- Chemical resistant

Applications – mixers, reaction vessels, rollers, fasteners, valves, moulds and welding tools.