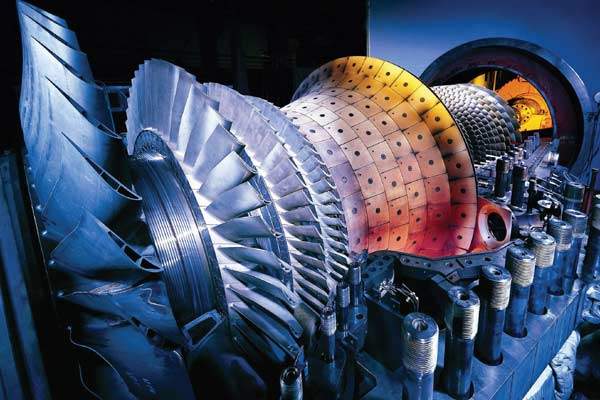

Holland-Controls has over 100 years of engineering experience in controlling gas turbines. Holland-Controls offers optimum control system solutions for existing turbines, reciprocating engines and related equipment. Our challenge is to offer dedicated services using off-the-shelf components from renowned manufacturers.

Customised controls systems for turbine installations

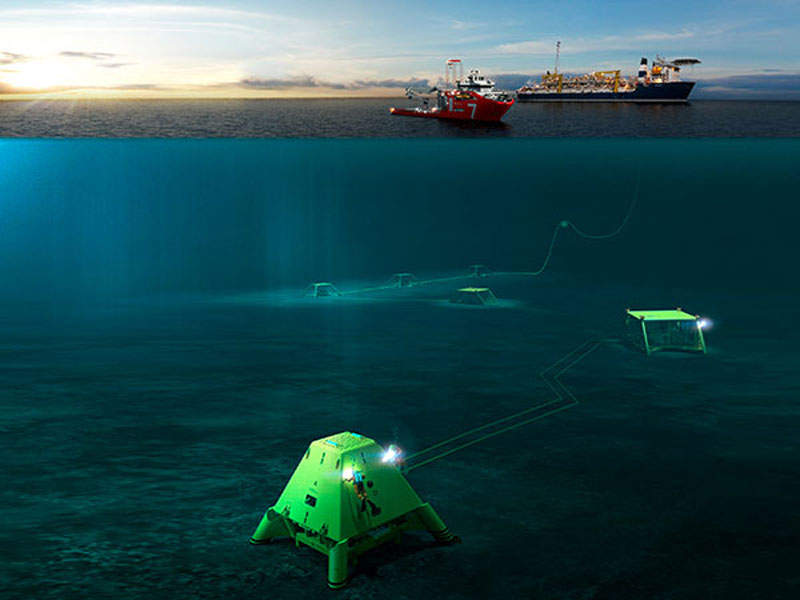

Holland-Controls is a specialist in the market of control systems for turbine installations and has vast experience in the oil and gas industry. Our capabilities include control systems for gas installations, reciprocating engines, steam turbines, station control systems and electric power management systems.

Turbine control system services

Holland-Controls offers services for control systems primarily used in the oil and gas industry as well as utility installations. We provide a complete spectrum of services, including specification, software and hardware design, parts procurement and system assembly, in-house and on-site testing, subcontracting and supervision for on-site construction, commissioning, handover, customer training and support.

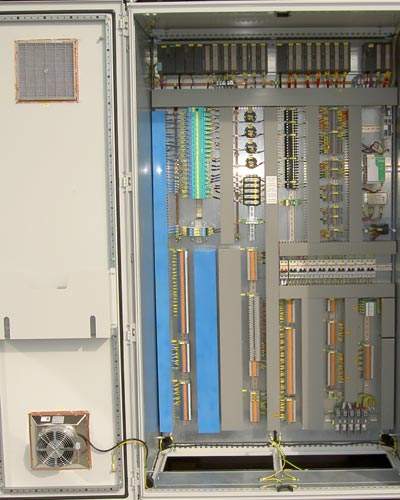

Control system retrofits / upgrades

Control systems tend to age faster than the equipment they are controlling due to rapid advancements in electronics and software. Retrofitting an old control system leads to a more efficient, accurate and reliable installation while lowering the cost of ownership. This results in better information about the operation of the installation, making it possible to operate engines closer to their limits without affecting engine life.

Turnkey control retrofits

The retrofitting of existing control systems is one of the important areas of Holland-Controls’ expertise. We offer various levels of control system upgrades (retrofits) to suit your needs. Control system upgrades can take place in various shapes and formats. This depends on the criticality of the system involved, the money that can justifiably be spent on it and the competence already available on site.

Limited control-system-only and complete system upgrades

The retrofitting of existing control systems is one of the important areas of Holland-Controls’ expertise. We offer various levels of control system upgrades (retrofits) to suit your needs, which can take place in various shapes and formats depending on the criticality of the system involved, the money that can justifiably be spent on it and the competence already available on site. This includes the following:

- Limited control system upgrades: if a particular component is causing trouble, but the installation is not highly critical, only the troubled component is replaced

- Control-system-only upgrades: if the instrumentation on the engine is sufficiently modern, it is worthwhile to consider only upgrading the control system

- Field instrumentation modernisation: for example, replacing the hydraulic fuel valve by an electric version or switch-type sensors by analog instruments to dramatically improve the diagnostics capability of the system

- Complete system upgrades: involves “stripping and upgrading everything with a wire” to achieve a system that is as new as when first installed and meets today’s standards and practices

Control system consultancy / engineering services

Holland-Controls provides consultancy / engineering services for the design of control system upgrades or to provide an independent second opinion on current projects. We can offer the following consultancy services:

- Design specification

- Second opinion engineering

- Factory acceptance testing

- Commissioning

Independent advice for control systems and projects

Holland-Controls can act as a consultant or independent engineer for a range of projects. Our expertise can help suppliers of controls equipment, but also customers in the process of buying equipment with the evaluating process.

Control system technical support

Besides consultancy, Holland-Controls can provide technical support for control systems. Our staff are technically qualified and know many installations and types of equipment inside out. We are particularly knowledgeable on En-Tronic Flexitrend systems and systems based on Allen Bradley Control-Logix and Siemens S7.

ISO-quality design

Holland-Controls complies to relevant European standards related to CE, ATEX and PED. Our uniform engineering methods and practices according to ISO 9001:2008 procedures enable reliable customer solutions.

References

Equipment dealt with by our engineers include Rolls-Royce RB211, Rolls-Royce Avon, Rolls-Royce Olympus, General Electric Frame 3, GE Frame 5, Solar Centaur, Solar Mars, Solar Taurus, Allison KB5, KC5 as well as Cooper Bessemer, Superior and Dresser Rand reciprocating engines.

Based on vast experience and a wide variety of units and applications, we can perform control system retrofits on almost any gas turbine and recip engine.

Our customers include Fluxys, Rolls-Royce, StatoilHydro, E.on Ruhrgas, OMV, EECT, Bayer, EECT, Petrobras and Halliburton. For full details, please visit our website.