ExproSoft is an independent consultancy firm headquartered in Trondheim, Norway. The company specializes in risk and reliability analysis of upstream systems, experience and reliability databases and data collection, qualification of well technology and development of customized drilling and well technology related software. Well integrity management and well specific, quantitative risk assessments are other services offered by the company to oil and gas companies worldwide.

Well System Risk and Reliability Assessment

ExproSoft has a strong focus on quantitative risk assessments (QRA) and reliability issues for well systems, subsea production systems and drilling / intervention technology. Applied studies are performed by a multidisciplinary team of experienced engineers with a practical approach and strong analytical competence. Example study topics include:

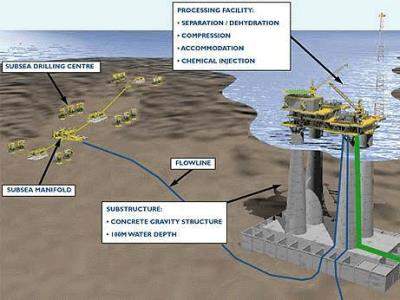

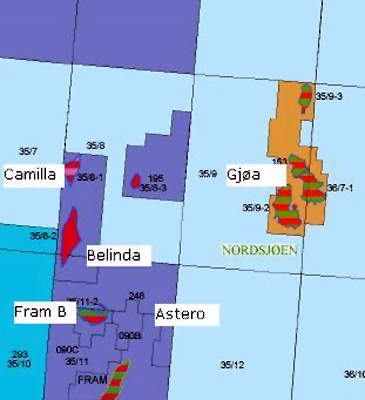

- Field development studies

- Intervention frequency studies

- Intervention systems studies

- Well completion optimization studies

- Specific downhole and drilling equipment reliability studies

- Well specific risk assessment (QRAs)

- Lifecycle cost / profit (LCC / LCP) analysis

ExproSoft’s staff has strong practical and analytical skills coupled with in-depth understanding of the functionality of well technology. As a result, the company is heavily involved in broader technical consultancy services for oil companies, typically definition of technical specifications of upstream systems and equipment and tender evaluations.

Offshore and Subsea Experience and Reliability Databases

ExproSoft has developed and is maintaining a number of experience and reliability databases which are used for in various decision making processes:

- ExproBase: modularized knowledge base for risk analysis, failure mechanisms, technology qualification, material selection, well equipment, etc.

- WellMaster: downhole completion reliability database

- SINTEF offshore blowout database: worldwide event database on offshore blowouts

- SubseaMaster: subsea production systems reliability database

- Subsea BOP master: reliability database on subsea blowout preventer systems

Most of these are joint industry projects (JIPs) where the participating oil companies provide data input, while ExproBase and SINTEF offshore blowout databases are based on public domain data which are structured and made commercially available to the industry through annual subscriptions.

Customized Offshore Field Software Development

ExproSoft has specialized in the development of Windows™ software and client / server databases, primarily for acquisition, visualization and analysis of data from offshore field operations. Development tools used are typically C++, VB, ADO, Oracle and Visual Basic, VB.NET. Web applications are also developed using Microsoft™ .NET, XML, XMS, DTD, ASP.NET and other suitable tools. ExproBase is the company’s first major development of a web application.

Well Integrity Management System

WIMS (Well Integrity Management System) is a new software tool for well integrity management. The system provides a uniform and structured approach for the handling of well integrity during the lifetime of a well. WIMS ensures that the information necessary for handling well integrity is available through one system, with a clear indication of the well barrier and integrity status at all times.

Qualification of Well Technology

ExproSoft has extensive activities on qualification of well technology. Procedures for qualification of well technology have been developed for several major oil companies and are implemented as part of their governing documentation. These procedures provide practical work procedures and tasks, which will ensure that a proper qualification process is carried out. ExproSoft has also assisted in developing prototype equipment qualification programs for oil companies and field development

organizations.

Several qualification projects have been performed by ExproSoft for specific downhole equipment items such as wellhead check valves, downhole safety valves, sliding sleeves, inflow control valves, gas lift valves, control line running equipment and others. These qualification efforts typically lead to design improvements and reduced equipment related intervention costs in the field.