Zebung Rubber Technology specialises in the design, manufacture and supply of premium-quality rubber hose solutions for the oil and gas industry.

The company’s product range includes hydraulic rubber, oil and chemical hoses, in addition to specialist units and related accessories.

We are also able to provide customised hoses based on a client’s specifications, such as size, thickness, conveying medium and working pressure.

Marine hoses for oil platform processes

Zebung’s comprehensive selection of rubber hose systems are designed to comply with the latest Oil Companies International Marine Forum (OCIMF) and ISO 9001 standards.

They are available with single and double carcass configurations in both floating and submarine varieties, depending on customer needs.

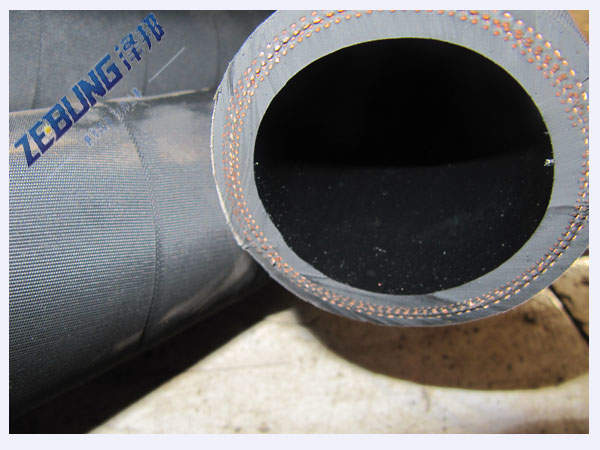

Our high-elasticity, smooth bore hoses are used for transporting oil and other liquid petroleum substances between loading and unloading vessels during offshore activities.

Our rugged oil suction and discharge hoses are made from elastomers that have been manufactured to be damage and temperature-resistant, and are suitable for liquids with temperatures ranging from -20°c to 82°c.

These systems have been optimised for continuous operation and are able to reach rapid flow velocities of 21m/s, with higher flow rates also possible with additional customisation.

Hydraulic hose systems for the offshore industry

Zebung Rubber Technology stocks an extensive range of highly flexible industrial hoses manufactured to the latest international safety standards, from general-purpose air and water hoses for machinery cleaning and cooling activities, to specialised units for custom applications.

Our hoses are available in both low and high-pressure configurations, as well as textile, steel wire and copper wire braided materials, depending on individual client requirements.

Zebung is able to provide liquefied petroleum gas (LPG), liquefied natural gas (LNG) and diesel suction systems developed for liquid fuel transport trucks, which are reinforced with helix steel wire and high-tensile textile cord for added protection. The SAE 100R3 and SAE 100R6 hydraulic oil delivery hoses are used throughout the oil and gas industry.

Our catalogue of products also includes a wide variety of food, chemical, sand blast, dry cement and plaster / concrete hoses, and we remain committed to providing customers with safe, high-quality and long-lasting hose solutions across a diverse cross-section of industries.

Dredging hoses for subsea environments

Zebung is able to supply specialist dredge hoses, which are lightweight, durable and highly flexible systems optimised for seabed dredging operations.

Our dredging hoses are available in several types, including a floating version equipped with a thin layer of foam that prevents water absorption, and an armoured variant reinforced with HB steel rings for applications with abrasive materials such as coral and limestone.

The company has also developed an innovative suction dredge hose lined with a smooth-textured interior, which has been proven to facilitate the conveyance of silt while mitigating excess substance build-up and corrosion damage. Additionally, our robust, heavy-duty discharge hose is resistant to impact damage, making it the solution for expelling waste seawater, silt and other matter in port and dock areas.

Zebung’s dredging hoses are supplied in diameters ranging from 150mm to 900mm as standard, with larger systems also available on a bespoke basis.

About Zebung Rubber Technology

Zebung Rubber Technology is a member of the China Rubber Industry Association, and has gained a reputation as one of the leading industrial fluid hose suppliers in the country over the past 15 years.

Our quality-assured products are manufactured in-house in our state-of-the-art, 63,000m2 production facility, and certified to BV, LR, CE, ECM and ISO 9001 standards.

The company has been named as one of the top four manufactures of floating oil loading and discharging rubber hoses, according the GMPHOM 2009 certification requirements.

Since Zebung first entered the global market in 2011, its customer base has grown to include companies in Singapore, Malaysia, Australia, the Middle East, Argentina, the US, the Netherlands, and the UK.