Umbilicals International (UI) designs and manufactures an extensive range of cables, hoses and umbilicals for use in harsh environments. UI serves the diving, subsea, ROV and oil and gas industries worldwide and is ISO 9001:2000 accredited by DNV, therefore meeting the highest standards demanded by the oil and gas industry.

A division of special cable systems manufacturer HL-Technologies, UI is located in Stafford, near Houston, Texas, in a 100,000ft² purpose-built manufacturing facility. Whether you need a basic electrical cable or a custom-engineered control umbilical, the required expertise in design and manufacturing is available from UI.

Harsh-environment cables

Umbilicals International is a leading designer and manufacturer of a comprehensive range of purpose-built cables for use in harsh environments. These cables are frequently used within the offshore oil and gas industry where extreme conditions require the highest quality in cable design and construction.

Cable designs range from a single copper-core conductor to cables with multiple copper cores, fiber-optics, hoses and steel armoring. UI’s manufacturing facility allows an almost unlimited variety of custom-built cables to be produced.

Intervention and workover umbilicals

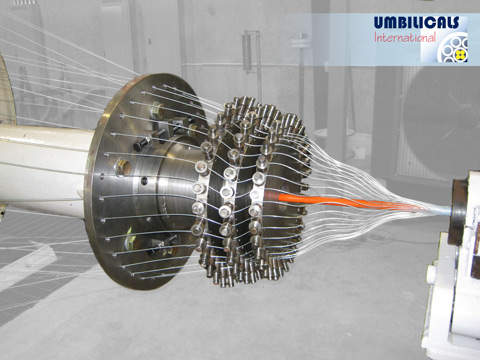

Umbilicals International has extensive experience in the design and manufacturing of a range of dynamic umbilicals for offshore use. Installation workover control system (IWOCS) umbilicals are custom-designed to meet the customer’s job’s specific requirements and tested to withstand the harsh operational conditions found offshore.

These intervention umbilicals may be hydraulic, electro-hydraulic or purely electrical and are designed and manufactured to withstand multiple deployments. Where the umbilical contains hoses, the hose type is selected to best suit clients’ needs and specifications, taking into consideration pressure rating, flexibility and fluid type.

The hoses are tied together with the cables to provide one secure bundle which is either jacketed or braided depending on the customer’s requirement/preference. Various end-fitting and electrical terminations are available to suit specific needs.

Control umbilicals / hoses

UI is a specialist in the design and manufacture of hydraulic and electro-hydraulic umbilicals for the upstream energy industry.

Subsea control umbilical applications include blow-out preventer (BOP) MUX control, wellhead control, flying leads and many other oilfield-related umbilicals and assemblies. These products are used to provide power and control of subsea and topside equipment in harsh and hazardous environments.

Divers’ umbilicals

UI’s line of diving umbilicals and hoses, Diveline, is designed to make life easier both underwater and on-deck for professional divers. Aquaflow, Texflow and Flexflow hoses, unique materials and cabled rope-like construction combine to produce the most flexible, controlled buoyancy umbilicals available today.

Diveline umbilicals not only improve diver efficiency but also reduce costs for the operator.

Underwater cables for diving umbilicals

Along with diving hoses and life-support umbilicals, UI also offers a full range of purpose-built underwater cables for use both separately and incorporated into diving umbilicals. All cables feature flexible, fatigue-resistant constructions and tough, abrasion-resistant polyurethane outer jackets.

In addition to these standard products, custom-designed cables can also be supplied to suit particular applications or customers’ requirements.

ROV tethers and umbilicals

As a harsh-environment cable manufacturer, UI has the design and manufacturing capabilities to provide a variety of remotely operated vehicle (ROV) cables. ROV tethers can significantly affect vehicle performance, so are invariably required to be highly flexible and robust.

UI has extensive experience designing and manufacturing tethers and umbilicals for the full spectrum of ROVs, from small electric eyeball systems to large hydraulically powered work-class vehicles.

Depending on the intended operating conditions, the ROV umbilical may be designed with strength properties obtained from kevlar/vectran or from a steel armor that provides extra protection for the cable. Electrical and optical signals are integrated into a cable design to meet the specific needs of the ROV.

UI is fully capable of providing both recognized ROV tether/umbilical designs or creating innovative new constructions to fit clients’ needs.

Design and manufacture

All designing and manufacturing is performed in-house by UI’s own engineers, operators and machinery at its comprehensive facility. In addition to UI, the HL-Technologies family also includes Geocable Systems (GS), who serves the complete seismic market. With the broad range of expertise possessed by UI and its affiliates, the highest quality is delivered with every project handled.