Dunlop Oil & Marine is an internationally recognised leader for the supply of API-rated high-pressure hoses, fluid-handling systems, and hoses and couplings to the oil, gas, chemical and other industries. Established over 45 years ago, it is now a wholly-owned subsidiary of Continental, based in Ashington Northumberland, with additional facilities in Aberdeen.

Fluid transfer components and systems

Dunlop Oil & Marine is recognised worldwide as an innovative designer and manufacturer of high-quality and technically advanced fluid transfer components and systems. Since its conception, the company has always been involved in design, research and development, and many of these efforts have been directed at the needs of the offshore, extractive and marine industries where durable and intrinsically safe products are essential.

The company has developed into an organisation capable of offering either stand-alone or fully-integrated systems, from a comprehensive range of flexible hose assemblies, to complete fluid transfer systems.

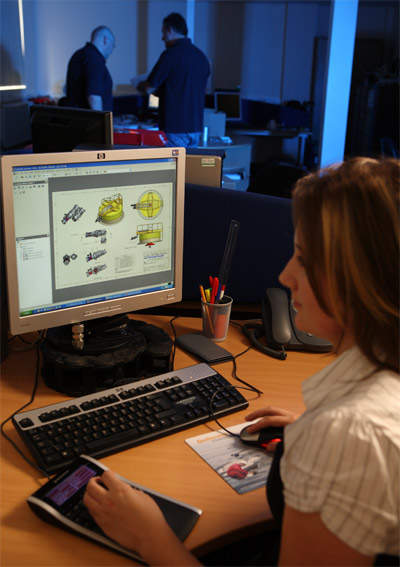

Fluid transfer system design, engineering and after-sales services

Dunlop Oil & Marine’s experienced design engineers, project engineers and after-sales support team offer a complete range of services from conceptual design, procurement, construction, installation and commissioning, through to user training and lifecycle maintenance of the product.

The company’s vision of delivering flexible engineering excellence is carried into the four main business areas of hose and couplings, high-pressure drilling and production hoses, fluid-handling systems and hose management. We supply high-quality and technically excellent products that are installed with major international oil, gas and other companies across the world.

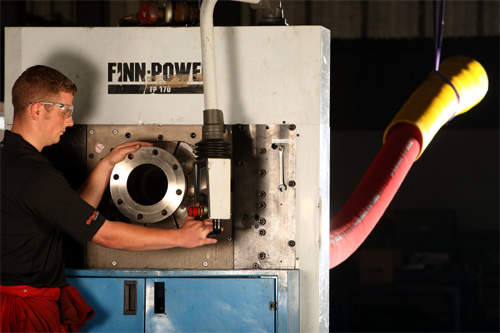

Industrial, hydraulic, fire-rated hoses and couplings

Dunlop Oil & Marine stocks a vast range of industrial and hydraulic hoses as well as its own range of fire-rated hoses under the trade name Fireshield, which now includes a fire-rated diesel oil hose. The company has recently introduced the Salamander range of floating hoses, which eliminates the need for cumbersome flotation collars. These hoses ensure a trouble-free, reliable and high-visibility solution for bulk material, potable water and diesel applications.

We also manufacture a complete range of couplings, from hose inserts and adaptors through to high-pressure, quick-disconnect and self-sealing couplings. Our specialist hoses are installed in diverse ambient conditions ranging from hot deserts to cold arctic.

High-pressure drilling and production hoses

We are responsible for the worldwide sales and marketing of high-pressure drilling and production hoses manufactured within Continental. The group is the world’s largest manufacturer and supplier of bonded high-pressure drilling and production hoses conforming to API 7K, API 16C, API RP 17B and API 17K.

Offloading systems, hose reels and handling systems

Our experience in the supply of flexible hoses and couplings is complimented by a comprehensive range of flexible hose storage and handling systems. These range from a single utility hose storage reel to a complete hose handling and fluid transfer system, as well as seawater intake systems. The company has extensive experience in the design and supply of offloading, loading and sea water intake systems for FPSOs and offshore platforms.

Hose management services

Our hose management services team offer complete packages, including hose specification, installation, future maintenance, inspection and training. Our hose analysis service ensures that the customer is supplied with the best hose for the job and when required we will install the hose on-site. In addition, our hose management services include the inspection of hoses on-site to evaluate critical hoses, reporting on their condition and suitability for use.

The qualified hose survey team has carried out inspections of hoses on offshore installations for the major international operators in the industry such as Shell, BP, Talisman, Ensco, Bluewater and Deutag. Training courses are also offered to customers to train their staff to carry out ongoing inspection of hose assemblies.

Quality in people, product and systems

Quality has always been of prime importance to the company and all staff are fully trained in maintaining the company’s quality assurance system. Personnel processes (recruitment, induction, training, personal development and appraisal) are managed through the company’s training and development programme.

With quality assurance at the forefront of Dunlop Oil & Marine’s design and production activities, it is company policy to build long-term relationships with clients and to sustain these through an ongoing commitment to understanding the business and striving to respond to the ever-changing demands of the industry.