Brugg Cables designs and manufactures a wide range of fiber-optic cables and accessories for distributed strain, temperature, acoustic and pressure sensing, resulting in the optimised monitoring and control of your critical infrastructure.

The fiber-optic cable is the sensor and thus the detector of the conditions on its full length to feed the control system with accurate status information. The results of the measurements to monitor your objects depend on the sensitivity of the cable. Mostly deployed under extremely harsh conditions, the cable has to provide application-optimised protection of the optical fibers but at the same time enable the highest sensitivity to events detected on the fibers.

The huge variety of applications and specific surroundings where the sensing cable is deployed define the large number of designs Brugg Cables can offer to its customers.

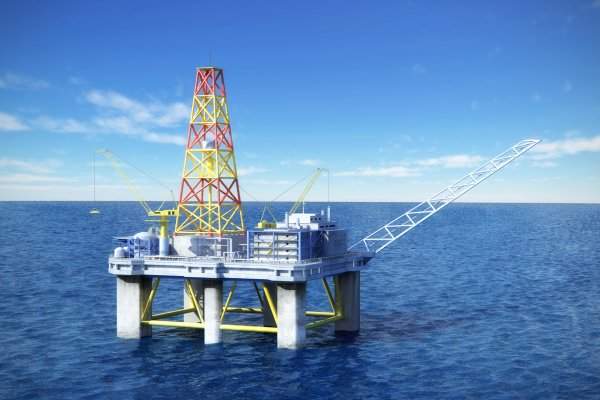

Fiber-optic cable sensing systems for the offshore industry

Distributed sensing systems support our customer by controlling their critical infrastructure with the detection of undesired incidents. The systems detect strain, temperature, acoustic / vibration, pressure, humidity and intrusion in interaction with light in optical fibers with Brillouin, Raman, Rayleigh or FBG methods. With regards to these sensing effects, Brugg Cable provides an open technology platform.

In the oil and gas industry fiber-optic cable sensing systems are used in the field of risers, umbilical cables, subsea, well, reservoir and seismic monitoring, as well as along pipelines, refineries and wells.

With Brugg’s competency and services you achieve safer and more efficient operation of your assets. Unlike other sensing cable manufacturers, Brugg Cables provides complete sensing cable system sets ready to plug into an interrogator unit.

Fiber-optic sensing cables for subsea monitoring

Brugg’s fiber-optic sensing cables are designed for many subsea applications, including in umbilical cables or for seismic monitoring of the sea ground and reservoir monitoring. These types of cables are hermetically sealed by steel tube for subsea and armoured for very tough applications and processes.

Downhole cable systems

Real-time monitoring of temperature and pressure within inaccessible and corrosive well systems protects peoples and critical installations. Our cables are specially designed for high temperature and elevated pressure, and can withstand an erosive environment. These distributed sensing systems can reduce your drilling and maintenance costs significantly.

Fiber-optic cables for monitoring of pipelines and refineries

By embedding the fiber-optic cable along the full length of a structure such as an oil or gas pipeline, the temperature or strain can be measured. Through immediate detection of strain or temperature differences in a structure, appropriate intervention can be taken to avoid extensive and expensive repairs before failures occur. Leakage and high/low pressure can be detected as well as any strain caused by ground motion and landslides.

Complete fiber-optic sensing services and accessories

With our extensive experience, Brugg Cables can provide engineering and consulting services at the beginning of a project. We are specialist designers and manufacturers of fiber-optic sensing cables and complete these cable sets with the needed termination of the cable or other specific assemblies and accessories. Enclosures, loops, mini loops, fan-outs, patch cables as well as connectors are available from Brugg Cables completely assembled and ready to use.

We support our customers during installation with the right fixtures, including anchors and brackets. Brugg provides the appropriate maintenance and repair splice set for each cable design as well as any necessary training of your staff to round off the services for your system during its whole lifecycle.