Karmsund Maritime Offshore deliver products and services to the oil and gas industry and specialise in the development, production and supply of patented products and solutions to the worldwide onshore and offshore petrochemical and process industries.

The company’s experienced personnel offer the oil and gas industry advanced product development, problem solving, installation, start-up and maintenance services. Its patented products and solutions are safe and cost-efficient.

Over the past few years there have been several cases of near-accidents due to leaks in flanges. Experience from offshore operation has shown that flanged connections in piping at high pressure in the presence of hydrocarbons constitute a large safety risk.

The KaMOS® method of avoiding leaks from such flanges provides a safety option and reduces the down-time associated with testing. This also reduces the loss in earnings as the result of downed production.

Sealing and surveillance of flanged connections

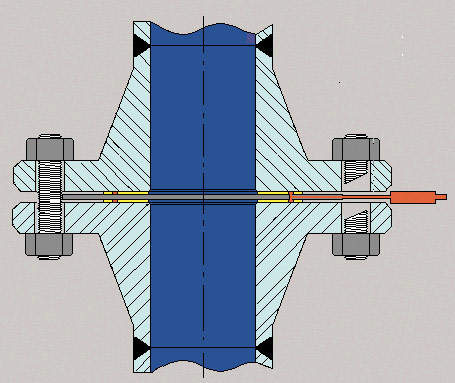

Using a unique patented technique, KaMOS has developed a sealing arrangement for pipe systems, which incorporates surveillance of flange conventions for all sizes.

KaMOS’ sealing method for flanged connections is new and able to provide a quick and effective control as to whether the flange connection is intact before the flange receives system pressure.

Flange leak testing

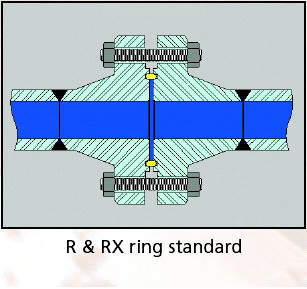

KaMOS’ new method of flange leak testing with ring joints measures whether tightness has been achieved on all sealing surfaces of the flange before it and pipe are subjected to internal pressure. Flange connections are also monitored for future leakages.

This method of flange leak testing permits flange integrity to be tested from the outside before system pressure is applied. This offers great benefits and reduces the test time for normal pressure and leak tests because repetitions of tests for leaky flanges can be avoided.

In the flange testing method, the annular space above and below the seal ring is pressurized using test gas. If no pressure loss is recorded during this pressurization, the seal is deemed tight.

Nitrogen and hydraulic test equipment

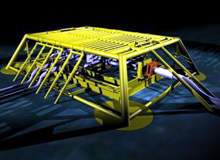

KaMOS offers nitrogen test equipment with a test range of 0-200bar for onsite use, and hydraulic test equipment with a test range of 50bar-400 bar for subsea / onsite use.

Portable valve actuator for manually operated valves

KaMOS’ portable valve actuator is an efficient solution for manually operated valves. It has been designed in co-operation with supervisors and operators who operate these units daily.

The KaMOS portable valve actuator gives cost savings and releases workmen for other work. The tool is time, cost and safety efficient. While it can take several hours to operate manual valves, using the actuator can take 10% off the time.

The KaMOS actuator can operate on valves in all positions and is reversible. It is driven with air pressure and one actuator can be used for several valves.

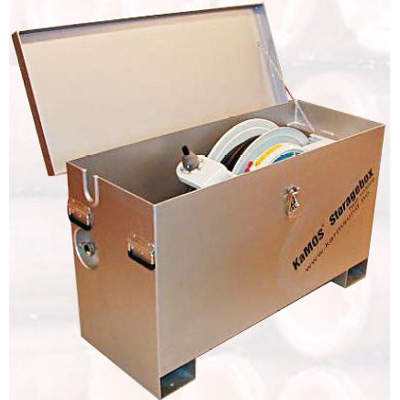

Storage box type 103000 for portable valve actuators

The KaMOS storage box type 103000* is designed to store the KaMOS portable valve actuators when not in use and also to supply the tool with air hose and adjust the air for the portable valve actuator. It contains a 20m air hose on a reel, a filter lubricator and a reduction valve. KaMOS recommends the use of this equipment together with the tools to lengthen the lifetime of the products.

The storage box is designed to be stationary at one place and to use the 20m air hose to serve a good area of the valves.

KaMOS offers a unique combination of product quality, professional skills and expertise from demanding applications to provide customers with the right technical solution, regardless of complexity, codes or standards.