Huhnseal A/B specialise in the production, design and supply of mechanical seals to the offshore oil and gas industry. Products include:

- Titanium seals for e.g. injection pumps: 15,000 rpm and 18 bar pressure on seal; Shaft diameter 65 mm

- Seals for centrifugal pumps, located 300 m below sea level: 3300 rpm and 50 bar pressure on seal; Shaft diameter 77 mm

- Titanium cargo seals for crude oil: 1860 rpm and 35 bar pressure on seal; Shaft diameter 99 mm

MECHANICAL SEAL MANUFACTURING FACILITIES

With an annual turnover of 34 MSEK. Huhnseal possess their own production facilities and currently have a staff of 31.

As well as the Huhn standard program, covering the needs of most applications, a large share of Huhnseal’s business involves customising seals to meet specific customer requirements.

A key strength of Huhnseal A/B lies in the company’s ability to work out adapted sealing designs, quickly and easy.

Customer Applications:

- Offshore

- Chemical Plants

- Energy

- Nuclear Powerplants

- Cargo Vessels

- Food and Biotech Industries

- Petroleum Plants

- Paper Mills

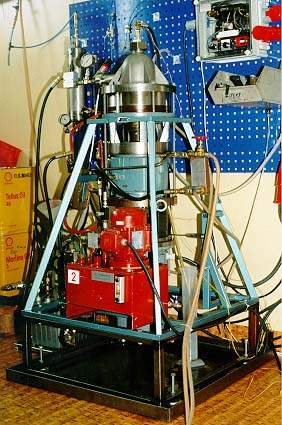

Working with the ceramics specialists, AC Cerama, Huhnseal have developed composite ceramic materials which have improved the pressure and speed performance of the mechanical seal rings. Ceramic materials are made using the hot isostaic pressing method and tested to simulate offshore conditions using a 3,600 rpm test rig, pressurised with hydraulic oil.

Sampling ceramics from a variety of worldwide suppliers, Huhnseal run extensive tests until the seal face collapses. Tungsten carbide and silicon carbide rings tend to break at between 10-25 bar whereas the AC Cerama ceramic withstands pressures up to 45 bar (although it has tested some materials to 70 bar with improved frictional behaviour). Tests have also been undertaken using diamond coatings whereby the friction coefficient is reduced by two thirds.

Huhnseal is a major supplier to Framo, using its standard materials – mainly for injection pumps which are run by high capacity pressure motors up to 6 MW and where the seals need to withstand pressures of 18 bar. Each seal is supplied with certification showing that has been tested to exact rig simulations.

Huhnseal seals are used on submersible pumps and early last year they supplied seals for eight Framo pumps which were installed on China’s Lufeng Field. These pumps lie at a depth of 300 metres below the seabed and this is the first time that the subsea pumps have been used for a floating production system. Each pump has a 2 MW (3,000 rpm) motor with seals for a pressure of 50 bar.

The seal casing is made of titanium which normally withstands pressures up to 45 bar however, Huhnseal have adapted the design to enhance the speed, size and balance ratio so that it can cope with the higher pressure. The seal faces are also made with a special silicon carbide.

Huhnseal have been working closely with Framo on the development of a subsea water injection pump and have supplied seals for two water injection pumps on the ETAP project. We are seeing an increased demand for multiphase handling as older fields require more water injection to recover the oil.

Huhnseal A/B work in close co-operation with their customers, testing every seal to make sure they have a fit-for-purpose design. For example, we have been working with one company to develop abrasive resistant ceramic seals for deep hole onshore wells where there is a lot of sand. In addition to its 3,600 rpm test rig, Huhnseal AB have installed a test rig capable of handling speeds up to 15,000 rpm.

Please also see:

For the Food Processing Industry – www.foodprocessing-technology.com – Huhnseal – Hygienic Mechanical Seals and O-rings for Agitators, Mixers and Pumps