CoorsTek offers the oil and gas industry a wide variety of extreme-service components and assemblies made from specialty materials including alumina, silicon carbide, tungsten carbide, metals and polymers.

Our products include an extensive range of wear and chemical-resistant products perfect for rigorous oil-field duty.

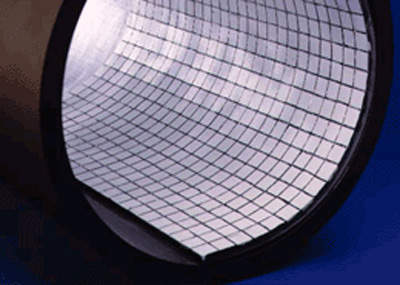

Ceramic wear brick

CoorsTek provides advanced ceramic wear brick for a variety of applications in mining, material processing and material handling. Our wear-reduction experts help you decide the best material, configuration and bonding method to ensure optimal performance.

Offshore mechanical seal components

We offer a wide variety of long-life, heat-stable and corrosion-resistant ceramic hard-face seals using high-grade aluminas, silicon carbide, tungsten carbide and specialty polymers.

Polymer bearings and bushings

CoorsTek consistently evaluates and researches new, advanced polymers to ensure optimal performance in next-generation product applications. We provide quick-turn prototypes for low-volume machined to high-volume injection-molded components in most bearing-grade materials.

Ceramic machining services for electronics

We provide complex, multi-axis ceramic machining for green machining, prototype manufacturing and general component finishing. As the largest laser-machining operation in North America and the UK, CoorsTek has unparalleled expertise in precision ceramic machining.

Machining services for high-purity metals

CoorsTek provides value-added metal machining services for high-purity metals.

Machining for high-performance plastics

CNC machines, simple lathes, grinders and polishers all help to provide the tight-tolerances required for high-performance plastic components.

Pulsation stabilizers

With over four decades of pulsation system experience, CoorsTek understands severe-service fluid-handling environments and assists design, production and maintenance engineers to optimize system productivity, prolong product life and reduce unscheduled maintenance.

Our SurgeTek™ pulsation equipment line extends pipelines’ and related components’ useful lives by reducing surges and other flow irregularities through gas-charged and maintenance-free (ZM-series) flow dampening and stabilizing systems.

Spring-energized PTFE seals

Spring-energized PTFE seals offer extreme-temperature, high-pressure, chemically inert, static and dynamic sealing for the most demanding applications. Our thin, flexible PTFE sealing jacket, made resilient by an internal energizing spring, applies a load to the sealing element at low pressures.

As the system pressure increases, the spring engages to create a highly efficient seal against the mating surface. The spring provides permanent resilience to the seal jacket and compensates for jacket wear, hardware misalignment or eccentricity.

Teflon-filled offshore plastic shapes and parts

CoorsTek provides Teflon-filled plastic shapes and parts in sizes up to 609mm (24in) in diameter. We also offer UHMW-PE materials, with rods up to 63.5mm (2.5in) in diameter, and tubes up to 32.75mm x 63.5mm (1.25in x 2.5in) in diameter.

Plastic tape and film manufacturing

Tapes are manufactured to the highest standard using high-temperature silicone or acrylic adhesives. Combining premium backing materials with high-performance adhesives, we manufacture some of the most specialized tapes available.

Many of our own PTFE-coated fiberglass fabrics are made bondable on one side and are converted into adhesive tapes. Our tapes are used in diverse industries including packaging, food processing, aerospace, electrics / electronics and molding.

Semi-finished plastic tubes and rods

CoorsTek offers a line of high-performance plastic semi-finished products in addition to our proprietary materials. These materials are used in diverse applications but primary emphasis is placed on wear, chemical compatibility, extreme temperature and low friction materials.

For all products, our experts can help you choose the best material and design to maximize performance and minimize cost.

Advanced zirconia material

State-of-the-art processes, precise material controls, and our dedication to operational excellence built our latest zirconia offering for severe service environments – Dura-Z™ partially-stabilized zirconia. This material offers a significant performance gain over competitive materials and our own standard TTZ.

Dura-Z zirconia material benefits include:

- 40% stronger than TTZ

- 60% greater fracture toughness than TTZ

- Equivalence to TTZ in all other measured properties

- Best-in-industry fatigue resistance behavior