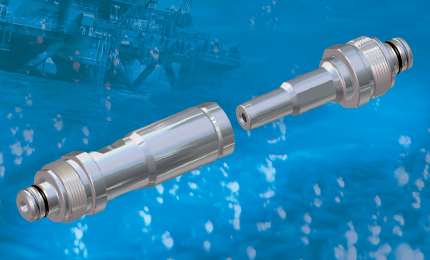

The original HMO design with integrated floatability provides the self-alignment of the plug into the socket. The long-stepped guiding of the plug and the large front cone of the socket ensure the perfect self-alignment at connection. This feature allows the total removal of constraints imposed by rigid pipes onto the coupling and on the internal seals at connection for an increased life of the couplings and long-lasting tightness.

Applications:

- High pressure and high temperature

- Chemical product injection

- Hydraulic circuits of actuator control

Fluids:

- Hydraulic fluids

- Corrosion inhibitors

- Paraffin inhibitors

- Methanol

Radial misalignment compensation:

- Up to 0.05in

Compensation of interface defaults:

- Up to 0.1in without tightness or flow loss

Long-lasting and reliable sealing

Double sealing barriers between plug and socket, as well as in the pocket recessed mounting:

- Primary tightness by high-tech metallic seal

- Secondary tightness by elastomer sea and anti-extrusion ring adapted to the fluids

Seals working in excellent conditions:

- No seal in the fluid jet eliminating any risk of seal ejection

- Total removal of constraints on the seals at connection

Easy maintenance:

- Sockets and plugs are accessible and dismountable from the front and totally independent of the pipes

Seals types:

- Primary tightness: metallic seals for a long life

- Secondary tightness: elastomer seals selected according to the fluids