A Cost-Effective, Robust Solution for Pipelines and Risers

The RapidPipe Connector is an innovative, high-performance system designed for pipelines and risers, offering cost-effective, durable, and sustainable connections. Engineered for quick installation, easy recovery, and reuse, it significantly reduces project costs and environmental impact.

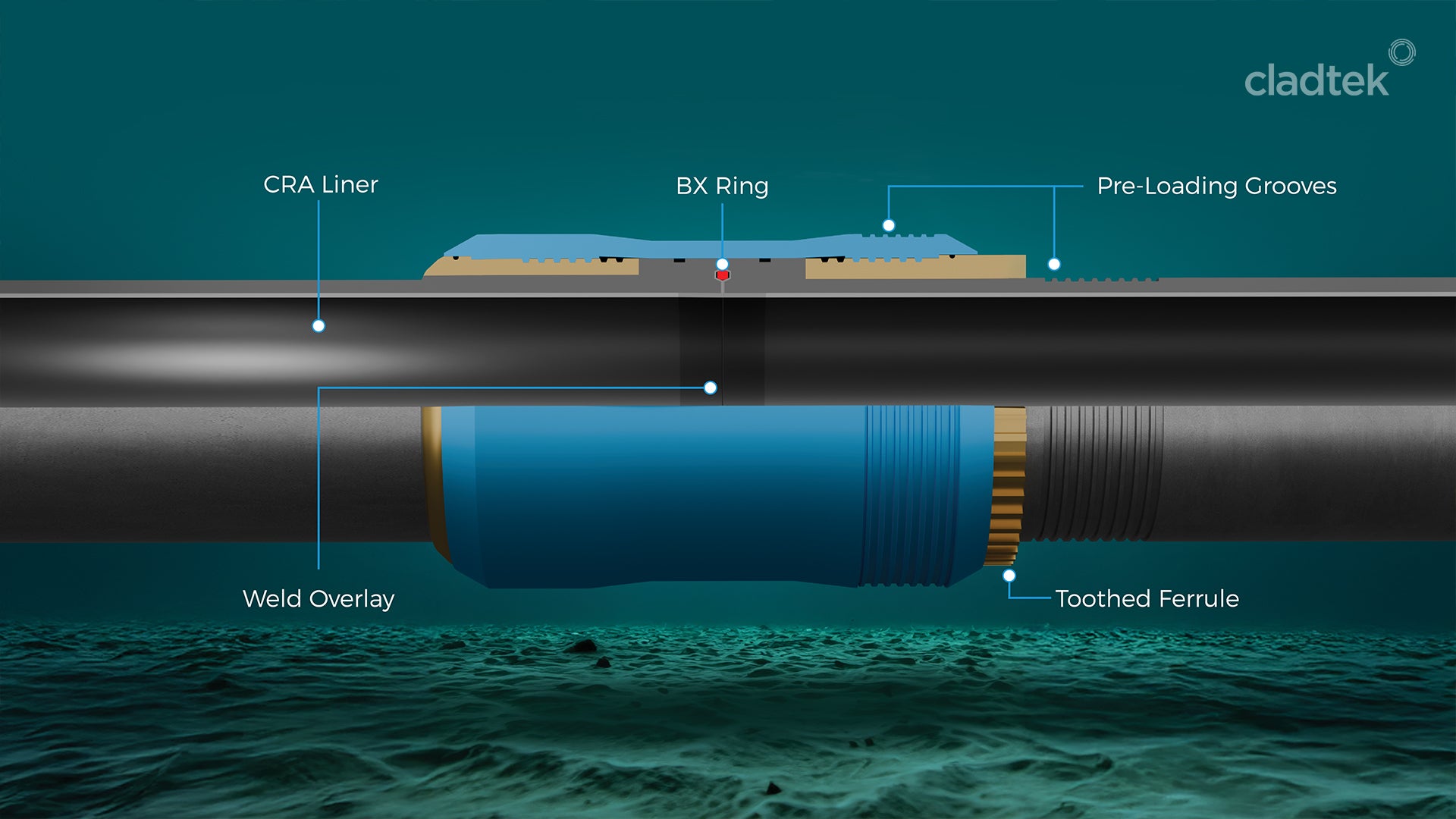

Unlike conventional welding, which can be slow, costly, and impractical in certain environments, RapidPipe Connectors provide a seamless, efficient connection method, making them ideal for harsh conditions and applications involving H₂, CO₂, and sour oil & gas. The system supports carbon steel (CS) pipes lined with CRA alloys, including titanium alloys, as well as HDPE/UHMWPE liners.

Key Features

Cost-Effective & Robust – A rigid pipe alternative to traditional flexible flowlines and risers, ensuring economic efficiency and durability.

Fast Installation – Onshore fabrication minimises vessel activities, reducing overall project timelines and enabling the use of vessels of opportunity such as large CSVs and drilling rigs.

Easy Assembly & Pre-Loading – The preloaded design ensures excellent fatigue performance, simplifying installation even in difficult conditions.

Recoverable & Reusable – Designed for recovery and reuse, significantly lowering operational costs and CO₂ emissions.

Sealing Integrity – Uses a proven BX ring seal with optional secondary metallic or elastomeric seals for enhanced reliability.

Specifications

Hubs: ASTM L5 Class 3 Grade F80

Sealing Face: UNS NO6625 Alloy 625

Maximum Working Pressure: 1,380 bar (20,000 psi)

Nominal Pipe Diameter Range: 6 inch – 20 inch

Temperature Range: +121°C to -40°C (wider on request)

Applicable Codes: API 17G, DNV ST-F101, DNV RP-C203

Applications

Designed for versatility across both the Oil & Gas and Renewable Energy sectors, RapidPipe is suited for:

- Pipeline and riser installations using J-Lay or S-Lay techniques

- CO₂ transportation pipelines

- Seabed mining risers

- Subsea structure and PLET connections

- TLP tether installations

- Caisson installations

Sustainability Advantages

RapidPipe reduces environmental impact by enabling onshore welding, NDT, and coating, which decreases transit emissions. Its recovery and reuse capabilities support oil, gas, water injection, EOR (Enhanced Oil Recovery), CO₂, and H₂ applications, reducing the need for decommissioning. Fast installation further minimises emissions from offshore vessels, while the robust connector design eliminates post-installation maintenance.

By combining cost efficiency, ease of installation, and environmental benefits, RapidPipe Connectors provide a reliable, high-performance solution for modern pipeline infrastructure.