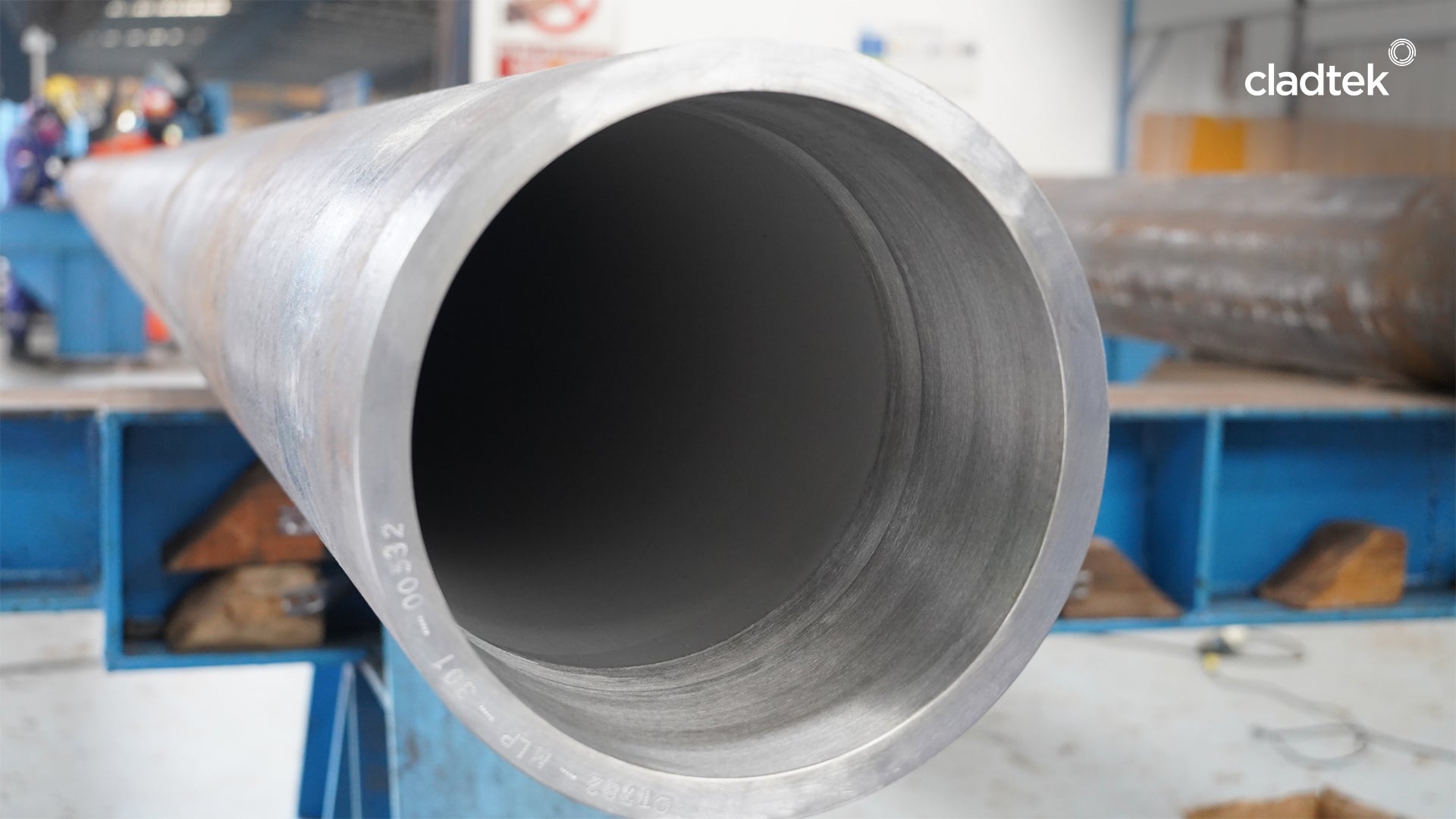

Mechanically Lined Pipe (MLP) has emerged as a leading corrosion-resistant pipeline solution, combining the strength of a carbon steel carrier pipe with the corrosion-resistant properties of a CRA liner. This bimetallic design ensures superior performance, extended service life, and significant cost savings compared to solid CRA pipes.

Cladtek has been at the forefront of MLP development since 2004, when we introduced weld overlay ends to Mechanically Lined Pipes—now a standard requirement across the industry. Our milestones include:

- 2005: Successfully manufactured the smallest MLP with a 4” diameter

- 2011: Produced our largest MLP for ExxonMobil

- Recent Success: Supplied 90 km of MLP for the Mero 1 project

Understanding Mechanically Lined Pipe

MLP consists of an outer carbon steel carrier pipe that provides structural strength and an inner corrosion-resistant alloy (CRA) liner that protects against aggressive transported fluids. These materials are mechanically bonded through interference fitting, with weld overlay cladding applied to both ends to enhance fit-up and installability.

Key Benefits of MLP

- Durability & Longevity – The mechanical bonding process ensures a tight connection between the CRA liner and carbon steel carrier, minimizing delamination risks and enhancing long-term performance.

- Versatility – Available in various sizes, pressure ratings, and CRA compositions to meet specific project needs.

- Ease of Installation – Designed for efficient welding, flanging, and coupling, reducing project time and costs.

- Reduced Maintenance Costs – The corrosion-resistant CRA layer minimizes maintenance and inspection requirements, lowering operational expenses.

- Cost-Effectiveness – Compared to solid CRA pipes, MLP offers up to 50% cost savings, making it a budget-friendly yet high-performance alternative.

Applications of Mechanically Lined Pipe

MLP is widely used in both oil and gas and renewable energy sectors for applications requiring superior corrosion resistance and durability.

Oil & Gas Applications:

- Offshore Pipelines – Withstands high pressures and corrosive conditions in offshore environments.

- Subsea Pipelines – Provides superior corrosion resistance against saltwater and chemical exposure.

- Sour Service Pipelines – Offers excellent resistance to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC).

- Water Injection Pipelines – Handles the corrosive effects of water injection operations with enhanced durability.

Renewable Energy & Emerging Applications:

- Geothermal – Suitable for steam gathering flowlines, downhole production tubing, liners, and water reinjection lines due to its high-temperature and abrasion resistance.

- Carbon Capture, Utilization & Storage (CCUS) – Used in CO₂ transportation pipelines, injection wells, and storage infrastructures for efficient CO₂ distribution.

- Risers – A reliable solution for dynamic & static risers, ensuring durability in harsh offshore environments.

Cladtek’s MLP Manufacturing Capabilities

Cladtek manufactures MLPs to the highest industry standards, offering a range of specifications to meet diverse project requirements.

Material & Size Specifications:

- Size Range: 4in – 36in

- Outer Layer (Carbon Steel): API 5LB, HYCS, LTCS in SMLS, ERW, HFW/HFI, LSAW

- Inner Layer (CRA Liner): 316L, 317LMN, 6 Mo, 904L, Duplex, Alloy 825, Alloy 625

- Available Lengths: 6m, 12m, DJ (24m), or custom lengths

Certifications & Compliance:

- API 5LD – CRA Clad and Lined Steel Pipes

- API 5LC – CRA Line Pipe

- DNV ST-F101 – Submarine Pipeline Systems

- Project-Specific Requirements