Superior Performance for Downhole Applications

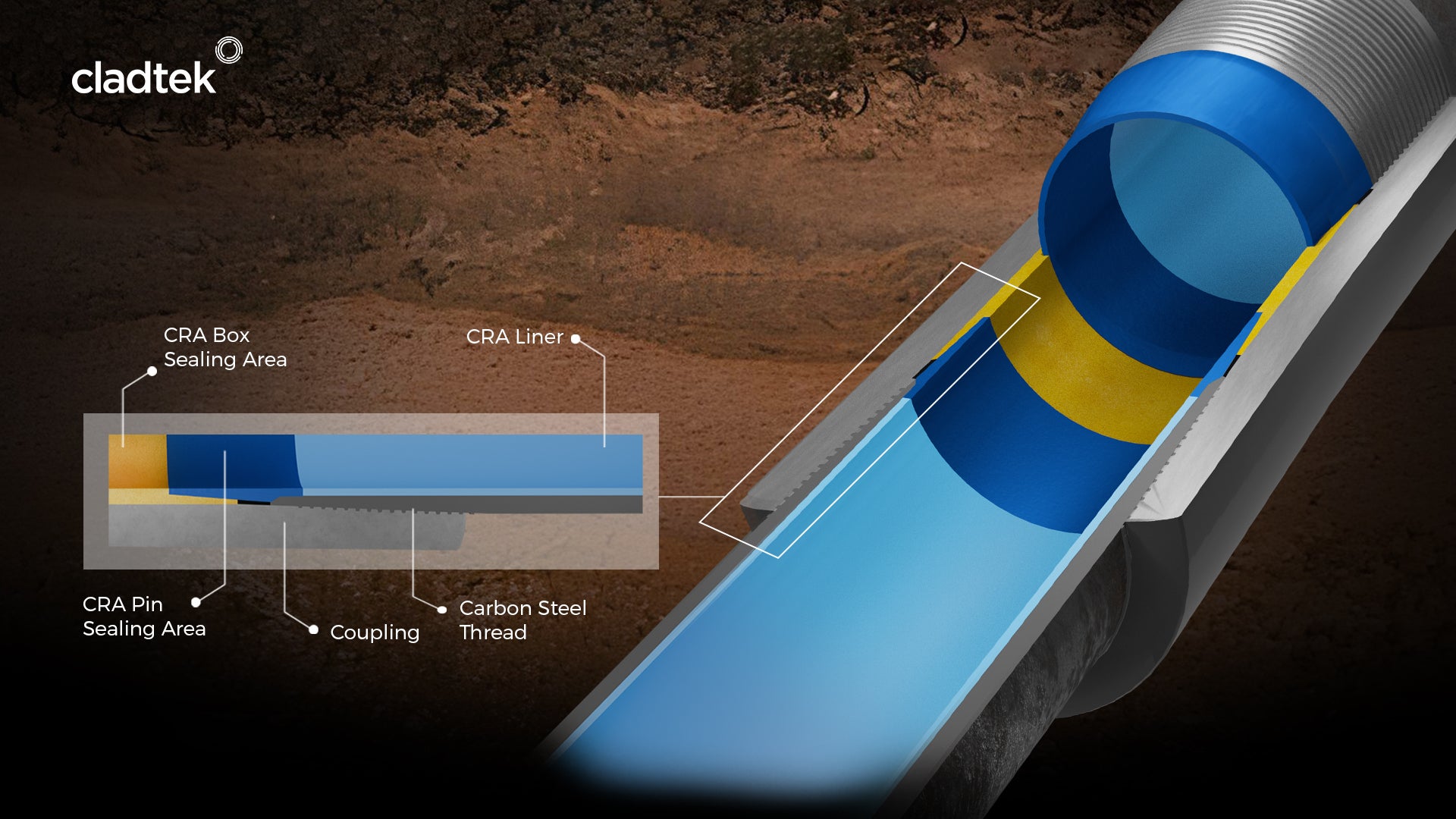

Cladtek’s Mechanically Lined Tubulars (MLT) combine the strength of a carbon steel outer layer with the corrosion resistance of a CRA lining, offering a cost-effective, durable, and high-performance alternative to solid CRA tubulars. Designed with premium connections featuring metal-to-metal gas-tight sealing, CRA-MLT provides enhanced corrosion protection while maintaining ease of handling and installation.

Applications of CRA Mechanically Lined Tubulars

Mechanically Lined Tubulars are widely used in downhole applications across multiple industries, providing superior corrosion resistance, high-temperature tolerance, and long-term reliability.

Geothermal & Water Injection Wells

- The CRA liner protects against corrosive fluids while withstanding extreme temperatures beyond the range of non-metallic liners such as GRE.

- Ideal for large-bore gas wells and water injection applications, ensuring durability in high-pressure environments.

Carbon Capture, Utilisation & Storage (CCUS) and Carbon Capture & Storage (CCS)

- Traditional CO₂ capture relies on 25Cr solid CRA tubulars—Cladtek’s MLT offers comparable performance at a lower cost.

- MLT technology is scalable, with increasing cost benefits as diameter size increases.

- Unlike GRE alternatives, MLT allows for cleaning and inspection interventions with minimal risk of damage.

CRA Mechanically Lined Tubulars – Specifications

Cladtek’s MLT is engineered to meet the most demanding industry requirements, ensuring high performance, cost savings, and long-term reliability.

Material and Size Specifications:

- Diameter Range: 4in – 20in

- Host Tubular: API 5CT

- Grade Selection: K55, L80, T95, P110 (including 13Cr/22Cr hybrids)

- CRA Liner Options: 316L, 317LMN, 6 Mo, 22Cr Duplex, 25Cr Super Duplex, 904L, Alloy 825, Alloy 625, Titanium & Titanium Alloys

- Sealing System: Premium connection with CRA metal-to-metal sealing, while the outer surface and threads remain carbon steel, reducing handling risks, galling, and the need for special tooling.

Key Features and Benefits

- Exceptional Corrosion Resistance – Withstands harsh environments, ensuring long-term performance.

- High-Pressure & High-Temperature Suitability – Rated for extreme conditions, including temperatures up to 370°C.

- Cost-Effective Alternative – Provides superior performance at a reduced cost compared to solid CRA.

- Scalability & Availability – More economical for larger diameters, with greater local content potential.

- Sustainable & Recyclable – The reversible manufacturing process allows for material recovery and reuse.

With industry-leading expertise and proven technological advancements, Cladtek’s CRA Mechanically Lined Tubulars provide a reliable, cost-effective, and high-performance solution for demanding downhole applications. Whether for geothermal, CCUS, or water injection, CRA-MLT ensures long-lasting durability, reduced maintenance, and exceptional corrosion protection.